Tearable elastic composite articles

A technology of elastic composite materials and products, applied in adhesive dressings, non-adhesive dressings, dressings, etc., can solve the problems of increasing manufacturing costs and achieve the effect of improving the transverse tearing characteristics of the web

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-10

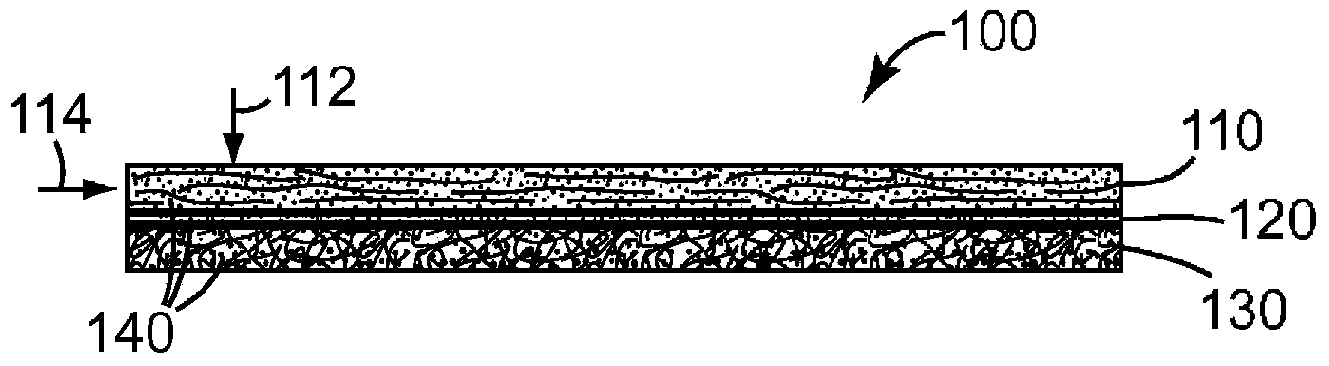

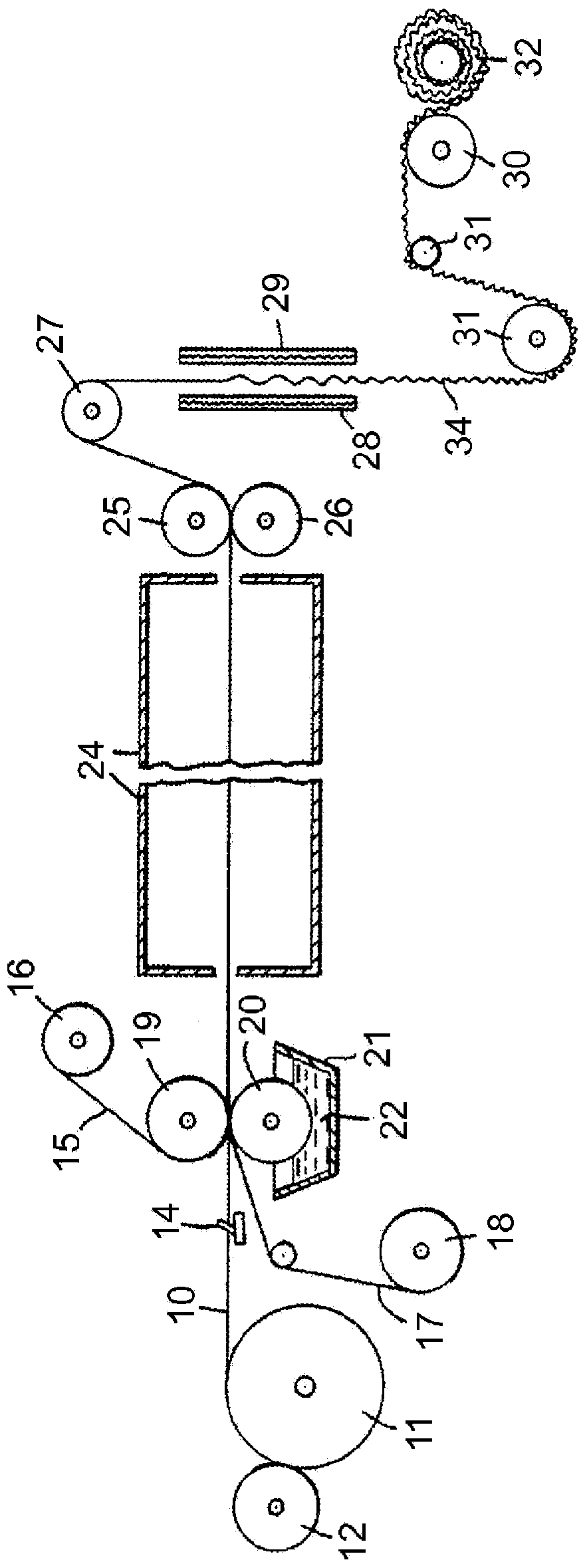

[0037] The elastic composite article of the present invention was prepared substantially as described in column 15, lines 18-30 of U.S. Patent No. 7,854,716 (Schuren et al.), except as follows:

[0038] • The spandex yarn used was 210 denier, 10 epi.

[0039] • The draw ratio is between 2.5:1 and 3.5:1.

[0040] • Replace one of the nonwoven webs in each composite with a polyester woven scrim from Milliken & Company.

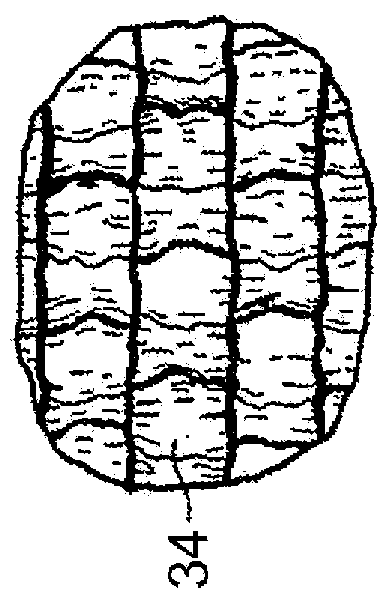

[0041] • Cut the resulting sheet material into strips (stretched dimensions) 3 inches wide and 5 yards long.

[0042] Specific compositions of composite articles, as well as properties of specific woven scrims are shown in Table 1 below. The properties of Examples 1 - 10 and comparative commercially available samples (Comparative Examples C-1 - C-5) were measured according to the description below. The results are shown in Table 2.

[0043] Table 1

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com