Films with Enhanced Abrasion Strength, Clarity and Conformity

A multi-layer film, linear low-density technology, applied in the field of MDO film, making marked products, and multi-layer film, can solve the problems such as difficulty in obtaining EVA film and rising price of MDO film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

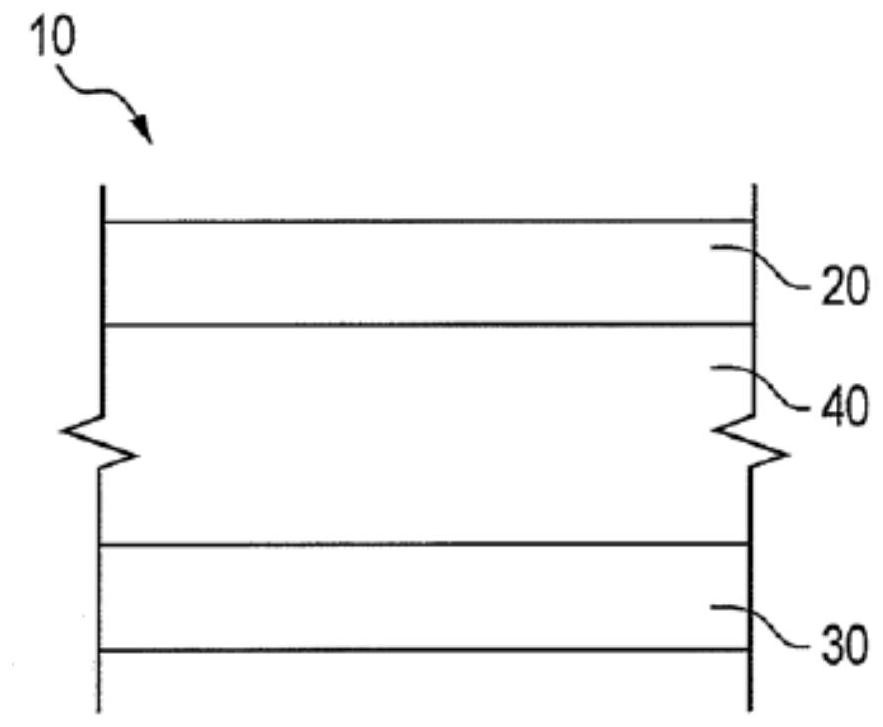

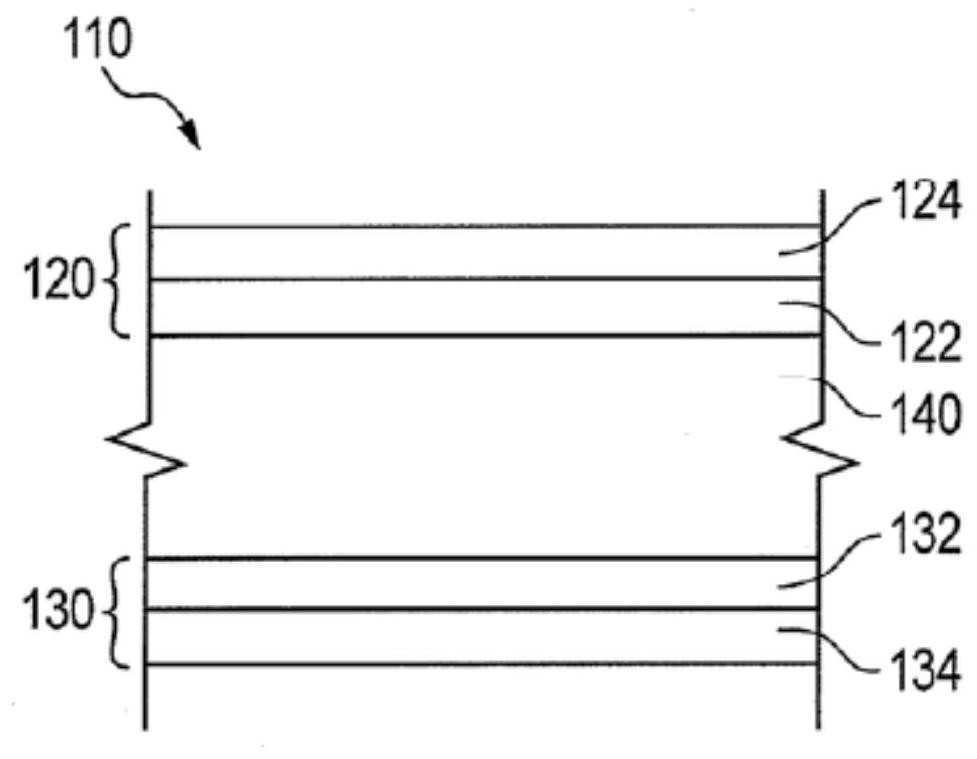

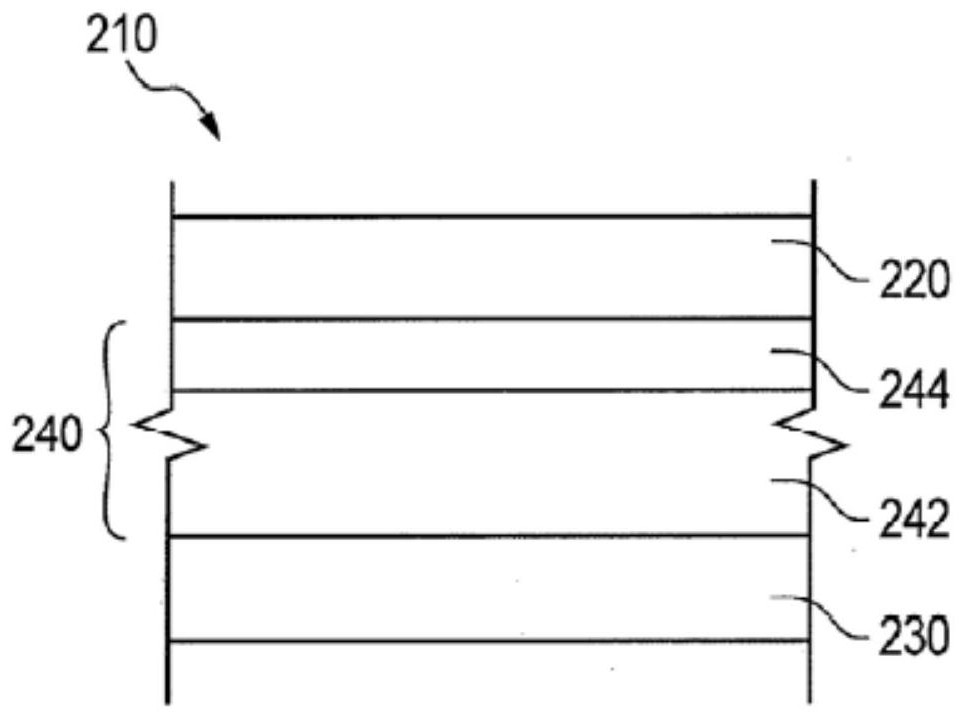

[0067] Various multilayer films according to the inventive subject matter were prepared. Each multilayer film includes a single core layer disposed between two skin layers. In some embodiments, the composition of the skin layers is the same, while in other embodiments, the composition of the skin layers is different. The weight ratio of the core layer is 70%, and the weight ratio of each skin layer is 15%. Table 1 summarizes the multilayer films with skin-core-skin arrangement and the composition of each layer.

[0068] Table 1 - Multilayer films of Examples 1-14

[0069]

[0070]

[0071]

[0072]

[0073]

[0074] Given that marked articles, including marked bottles, are likely to be conveyed on metal rails on high speed production lines or metal rails lined with high density polyethylene, enhanced abrasion resistance is desirable. Wall friction encountered by marked articles can lead to surface defects, including scratches or marred markings, which are aes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com