Multifunctional waste fluff classification treatment and recycling device for garment processing

A technology of a recycling device and a processing plant, applied in the field of garment processing, can solve the problems of inconvenient handling, poor drying effect of waste velvet, easy dripping of water into the drying box, etc., so as to improve the waterproof effect and improve the anti-slip effect. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

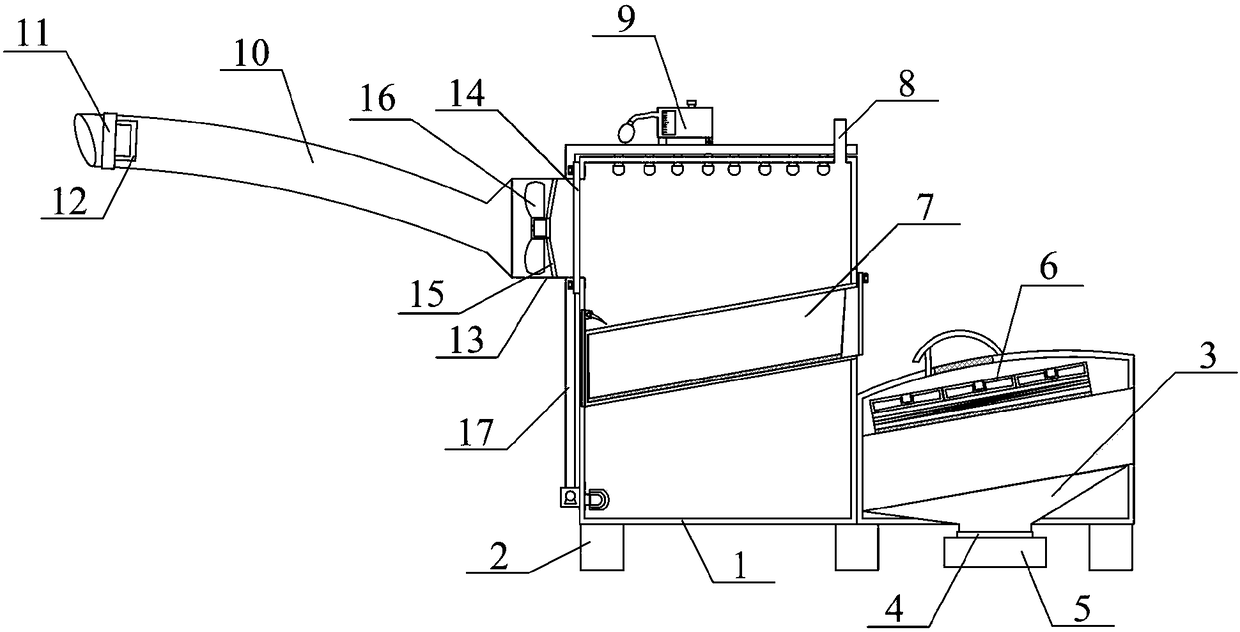

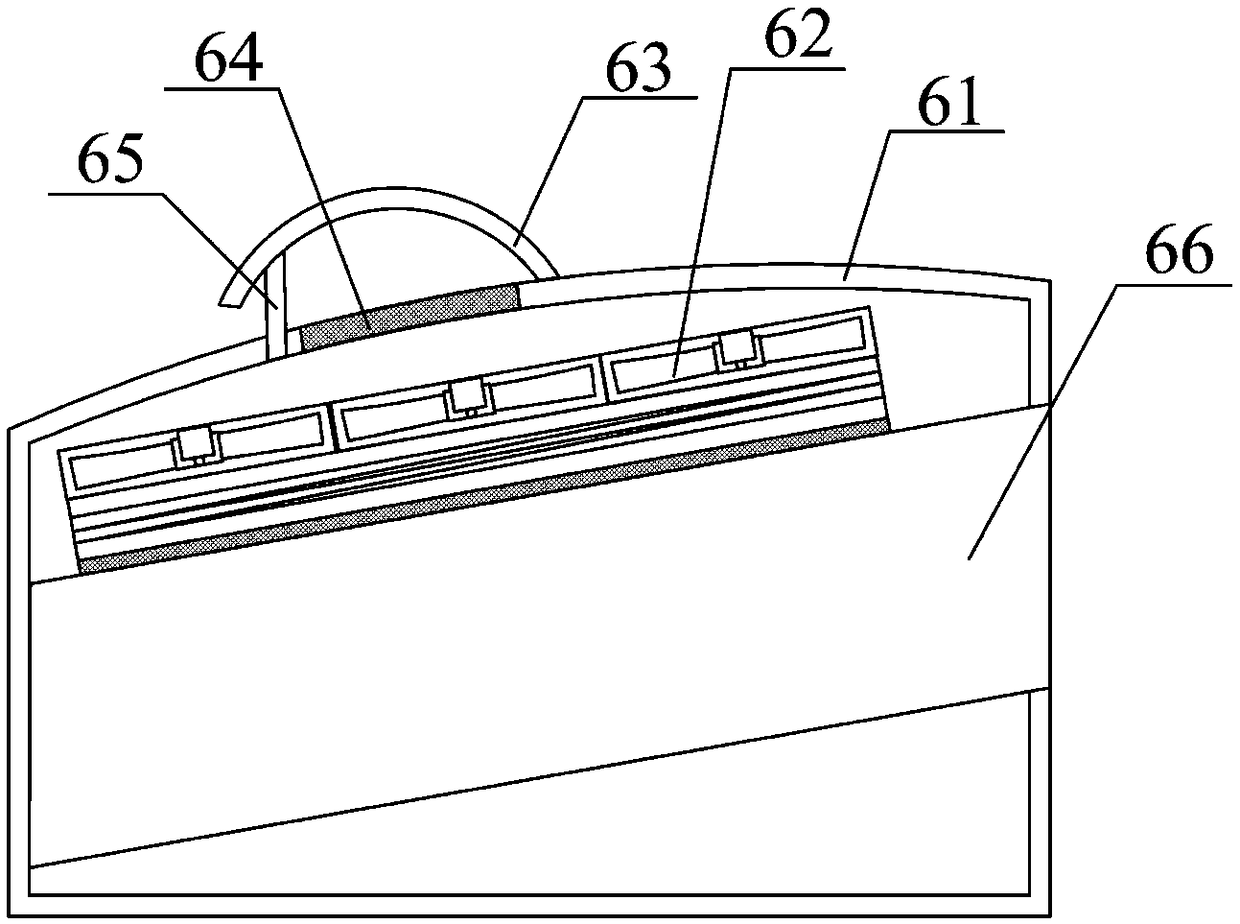

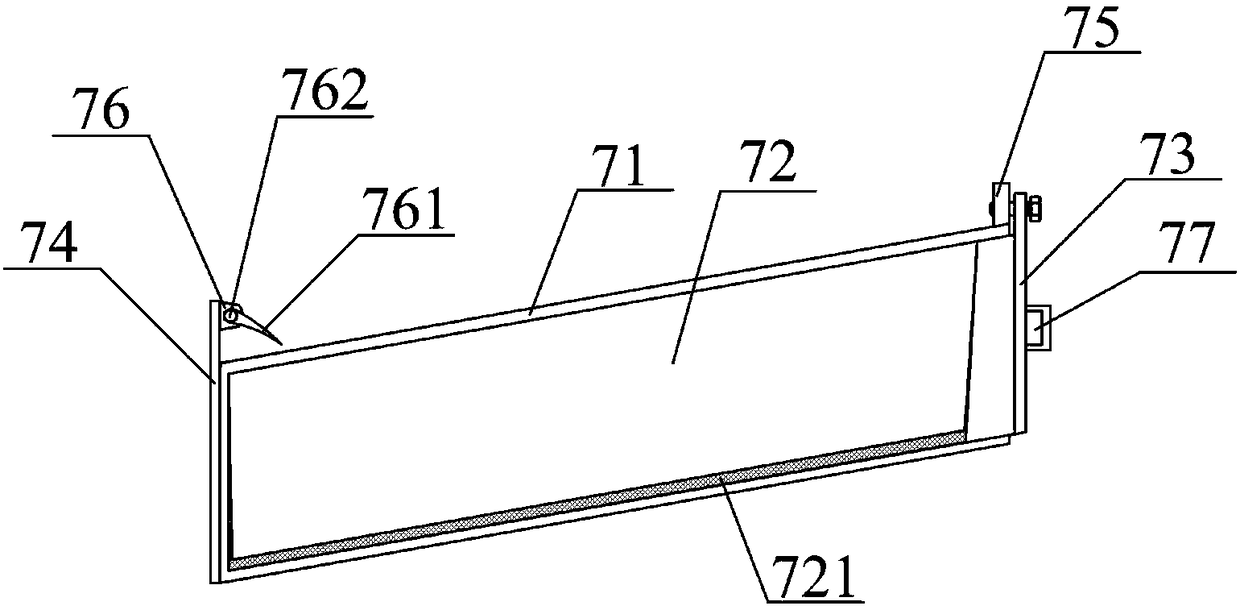

[0037] as attached figure 1 to attach Figure 6 shown

[0038] The present invention provides a multi-functional waste velvet sorting, processing and recovery device for garment processing factories, which includes a cleaning box 1, a rubber support block 2, a waste liquid diversion bucket 3, a liquid outlet pipe 4, a liquid storage box 5, and a velvet recovery heating and drying device. Dry frame structure 6, fluff cleaning sieve hopper structure 7, air outlet duct 8, disinfectant will add tank structure 9, exhaust pipe 10, fixing ring 11, handle 12, fan frame 13, fixing plate 14, fan bracket 15, The exhaust fan 16 and the water circulation spraying conduit structure 17, the rubber support blocks 2 are respectively glued to the left and right sides of the bottom of the cleaning box 1 and the bottom left and right sides of the fluff recovery heating and drying frame structure 6; The bolts of the funnel 3 are installed on the inner lower part of the fluff recovery heating and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap