An adjustable piezoelectric ceramic oil-sealed hydrostatic bearing

A piezoelectric ceramic and hydrostatic bearing technology, applied in the direction of bearings, shafts and bearings, bearing components, etc., can solve the problems of reduced bearing capacity, reduced bearing cavity pressure, and increased bearing temperature, so as to avoid the reduction of bearing capacity, Low power consumption and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

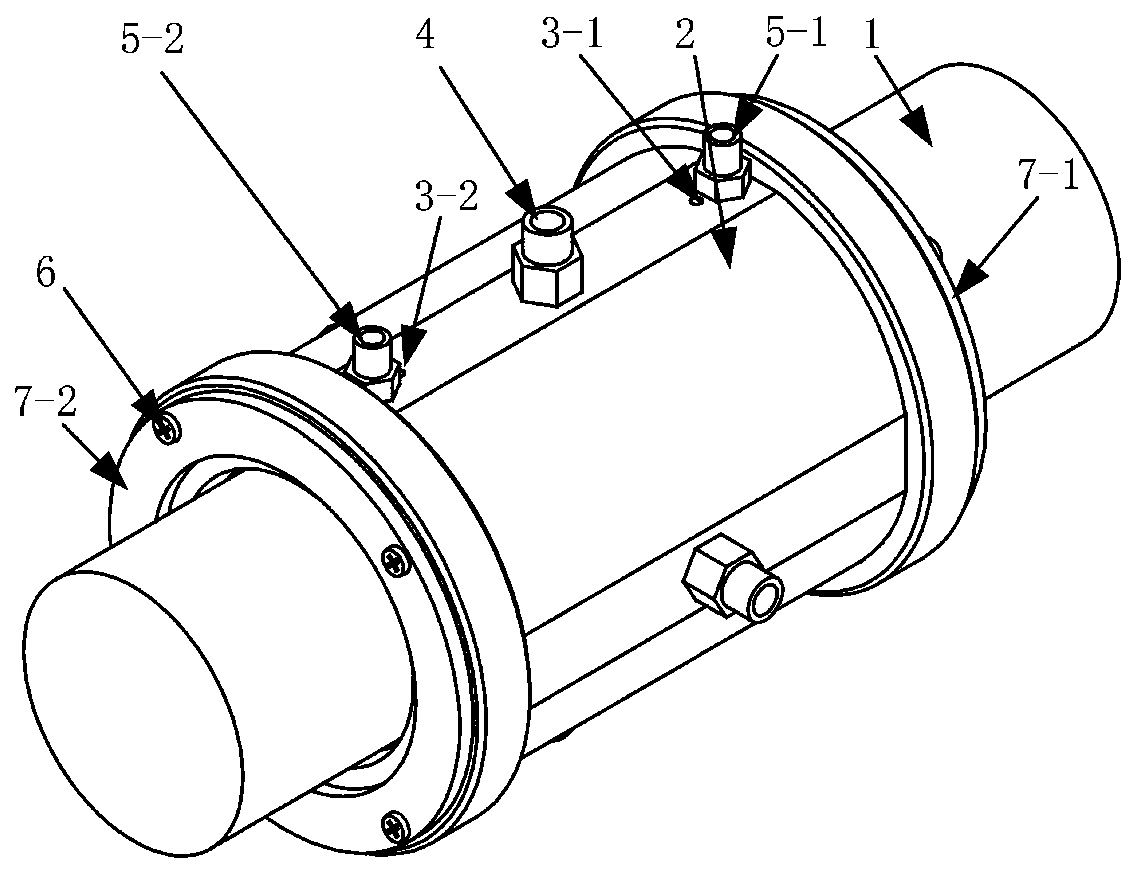

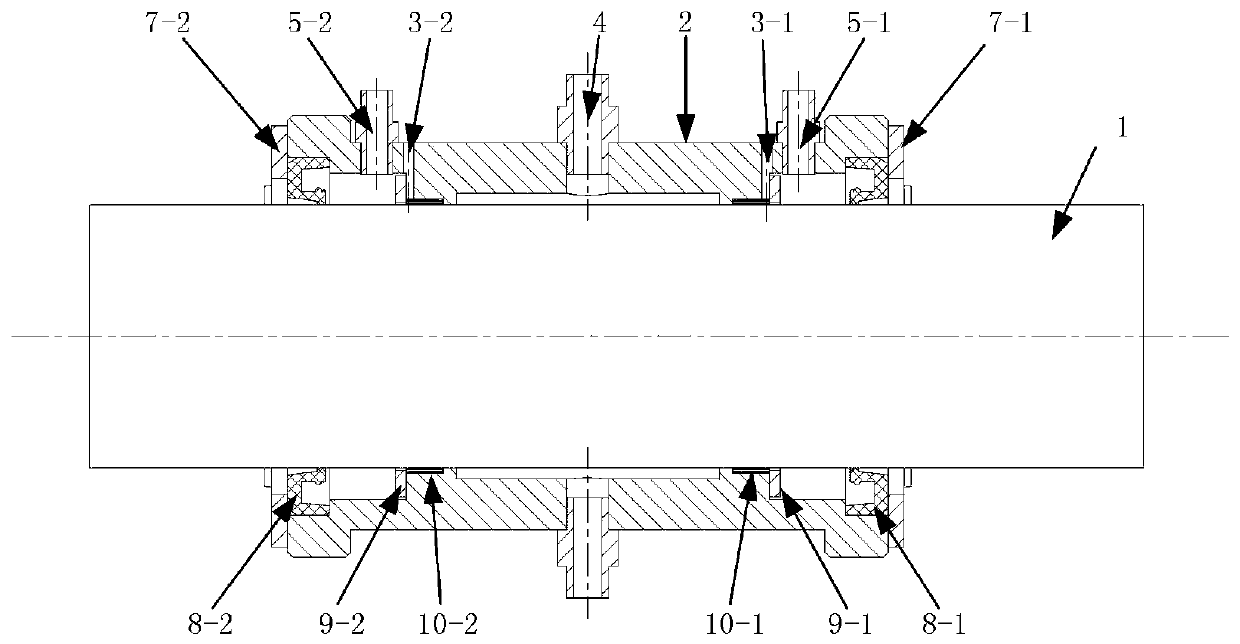

[0021] A preferred embodiment of an adjustable piezoelectric ceramic oil-sealed hydrostatic bearing of the present invention, the bearing is a left-right symmetrical structure, including a shaft 1 (50 mm in diameter), a stator 2, and a first outer retaining ring 7- 1. The first skeleton sealing ring 8-1, the first inner retaining ring 9-1, the first piezoelectric ceramic bimorph 10-1, the second outer retaining ring 7-2, the second skeleton sealing ring 8-2, the second Two inner retaining rings 9-2 and the second piezoelectric ceramic bimorph 10-2; the overall structure of the bearing is as follows figure 1 and figure 2 shown.

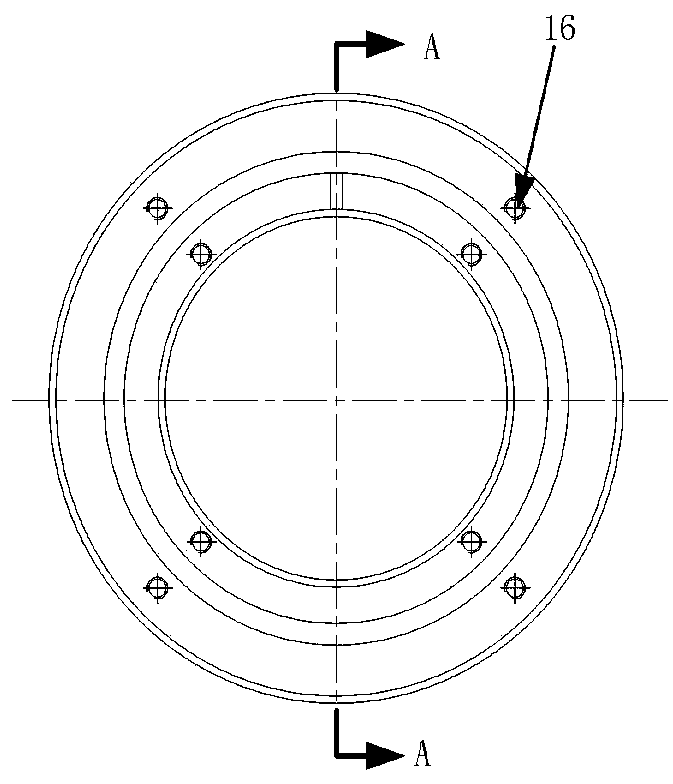

[0022] The stator 2 is a rotating body, such as Figure 3-4 As shown, there are five coaxial chambers in the revolving body, from left to right respectively the first chamber 23, the second chamber 24, the third cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com