Baking oven and photoresist pre-baking method

A baking furnace and baking cavity technology, applied in optics, optomechanical equipment, instruments, etc., can solve the problems of uneven substrate photoresist film thickness, uneven heating, uneven photoresist film thickness, etc., to avoid photoresist Non-uniform film thickness and line width, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

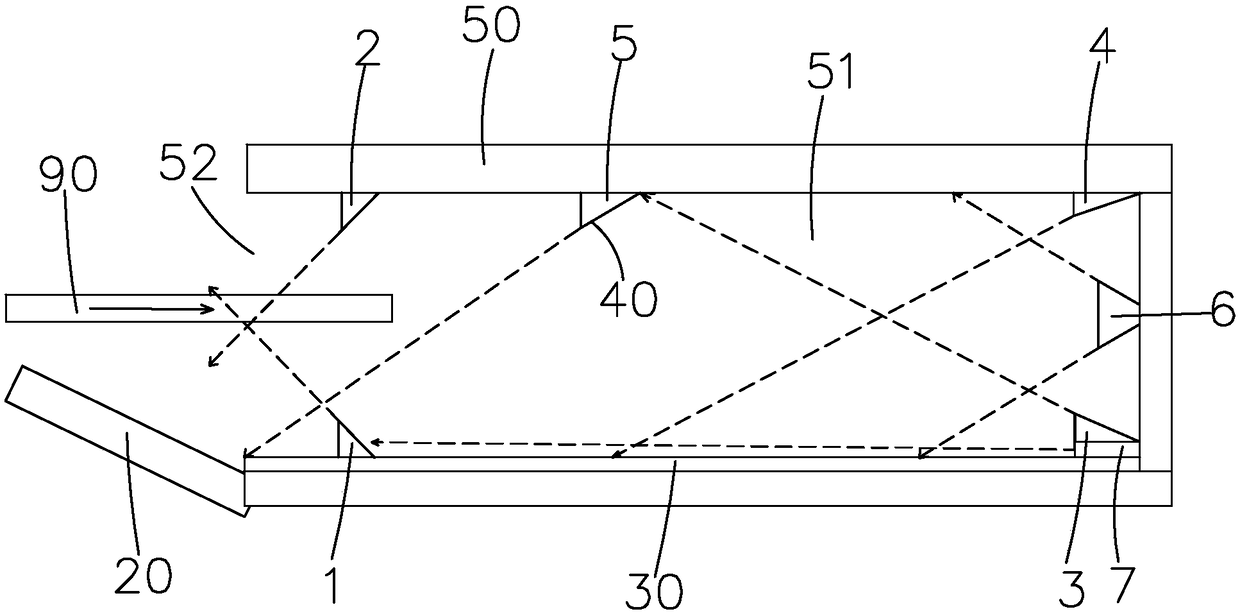

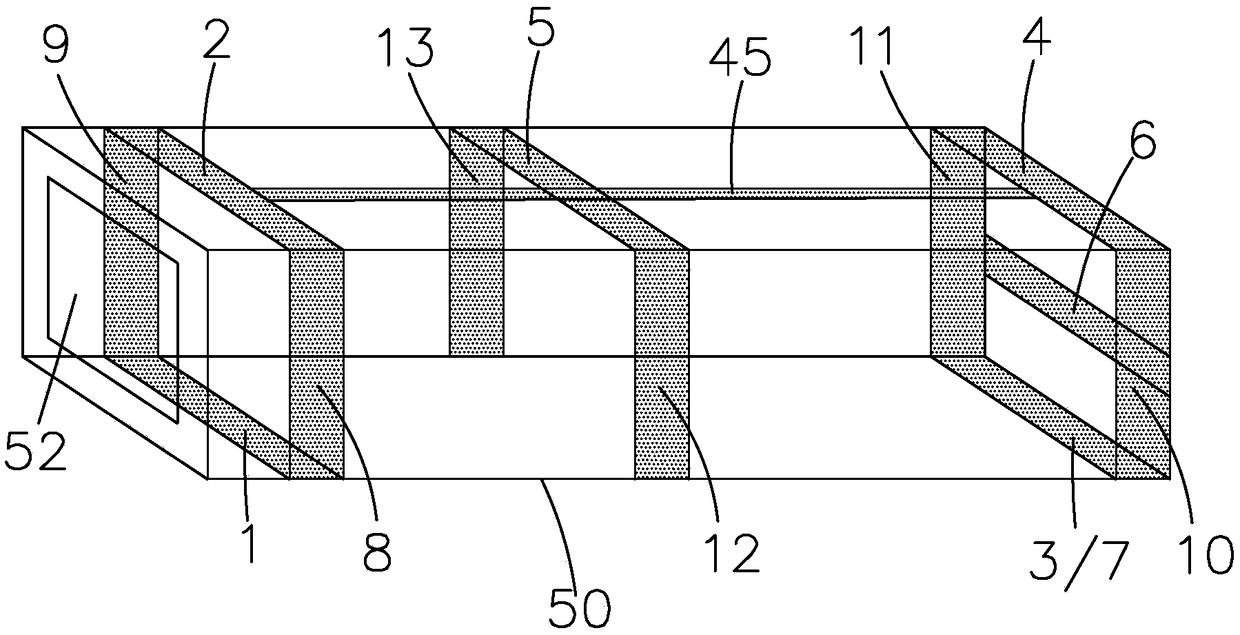

[0050] see figure 1 , the present invention firstly provides a kind of oven, comprises:

[0051] A furnace body 50, the inside of which is a baking cavity 51, and one side of the furnace body 50 is provided with an entrance and exit 52;

[0052] The switch door 20 is installed at the entrance and exit 52 of the furnace body 50;

[0053] The heating plate 30 is arranged at the bottom of the baking cavity 51 and is used to heat the substrate 90;

[0054] A plurality of jet pipes 40 are arranged in the baking cavity 51;

[0055] When the switch door 20 is opened, the plurality of gas injection pipes 40 are used to spray hot gas to the inlet and outlet 52 to prevent the gas outside the baking cavity 51 from entering;

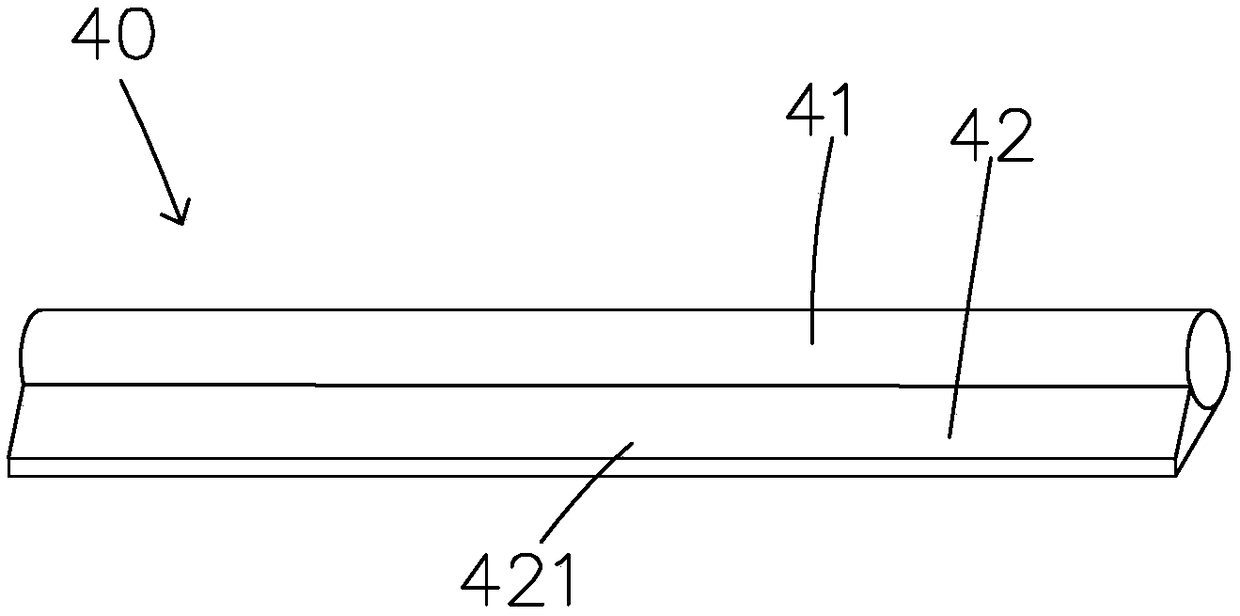

[0056] Such as image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com