Water-bath type sterilizer temperature reduction control method

A control method and sterilizer technology, applied in the field of large infusion, can solve the problems of high cumulative F0 value, long duration, unfavorable for quality control of thermally unstable products, etc., to reduce the increase of related substances, shorten the cooling time, reduce Effects on the likelihood of adverse drug reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

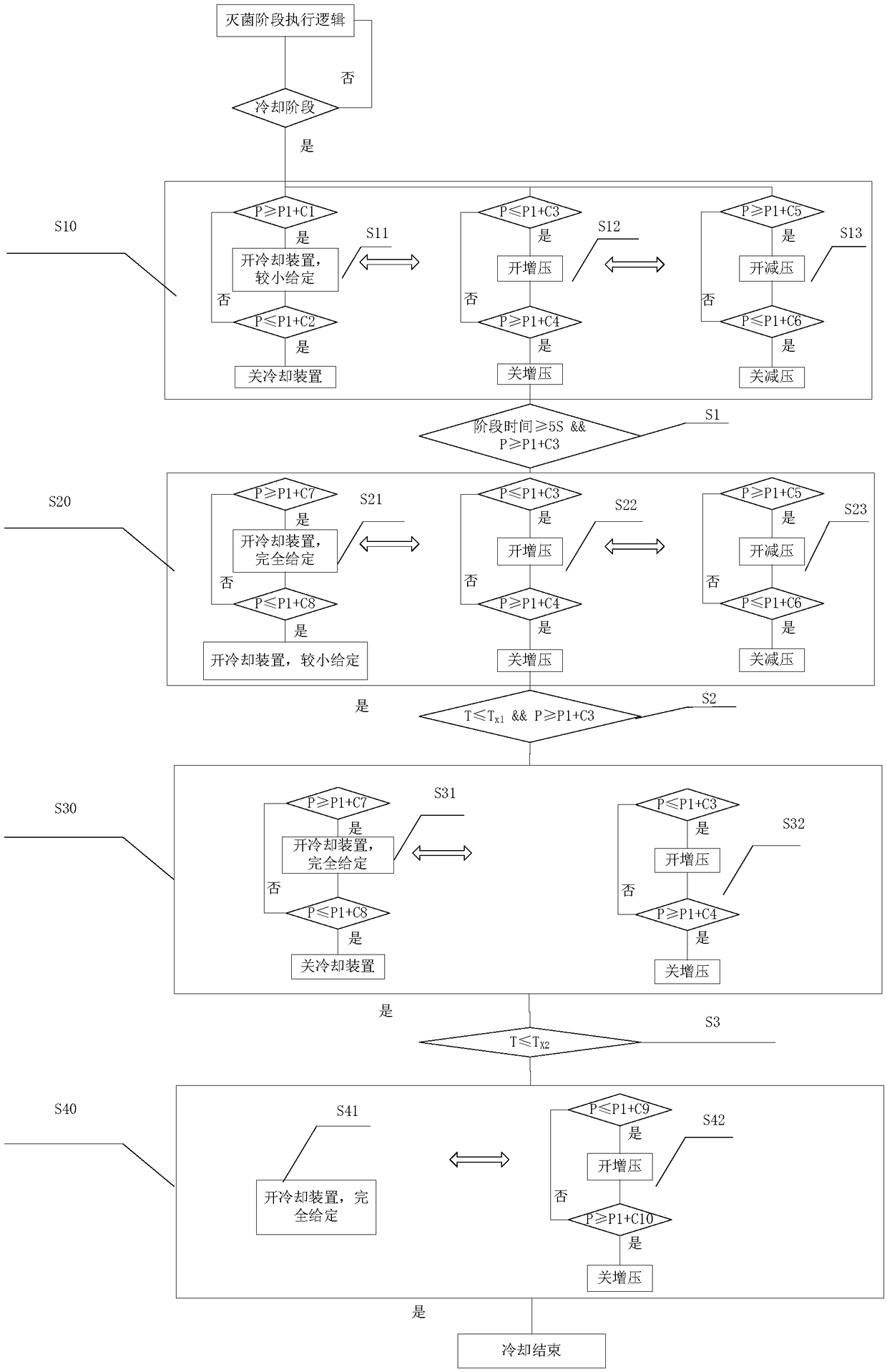

[0027] Such as figure 1 Shown, a kind of water bath type sterilizer cooling control method comprises the following steps:

[0028] Pre-set sterilization temperature, cooling temperature, pressure parameter A, pressure parameter B, pressure parameter C, pressure control deviation parameters C1-C10, stage temperature setting value Tx1, stage temperature setting value Tx2;

[0029] Step S10: In the initial stage of sterilization transfer to cooling, obtain the temperature T and pressure P in the cabinet, and start timing, calculate the theoretical pressure value P1 through the formula P1=A*(T-B)+C, and calculate the theoretical pressure value P1 through the theoretical pressure value P1 and pressure Control deviation parameters C1-C10 to obtain 5 corresponding pressure upper limits respectively: pressure upper limit 1, pressure upper limit 2, pressure upper limit 3, pressure upper limit 4, pressure upper limit 5 and 5 corresponding pressure lower limits respectively: pressure low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com