Shoe pad composition, shoe pad structure and manufacturing method thereof

A manufacturing method and composition technology, applied in the field of breathable insole structure, capable of solving problems such as airtight insole structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

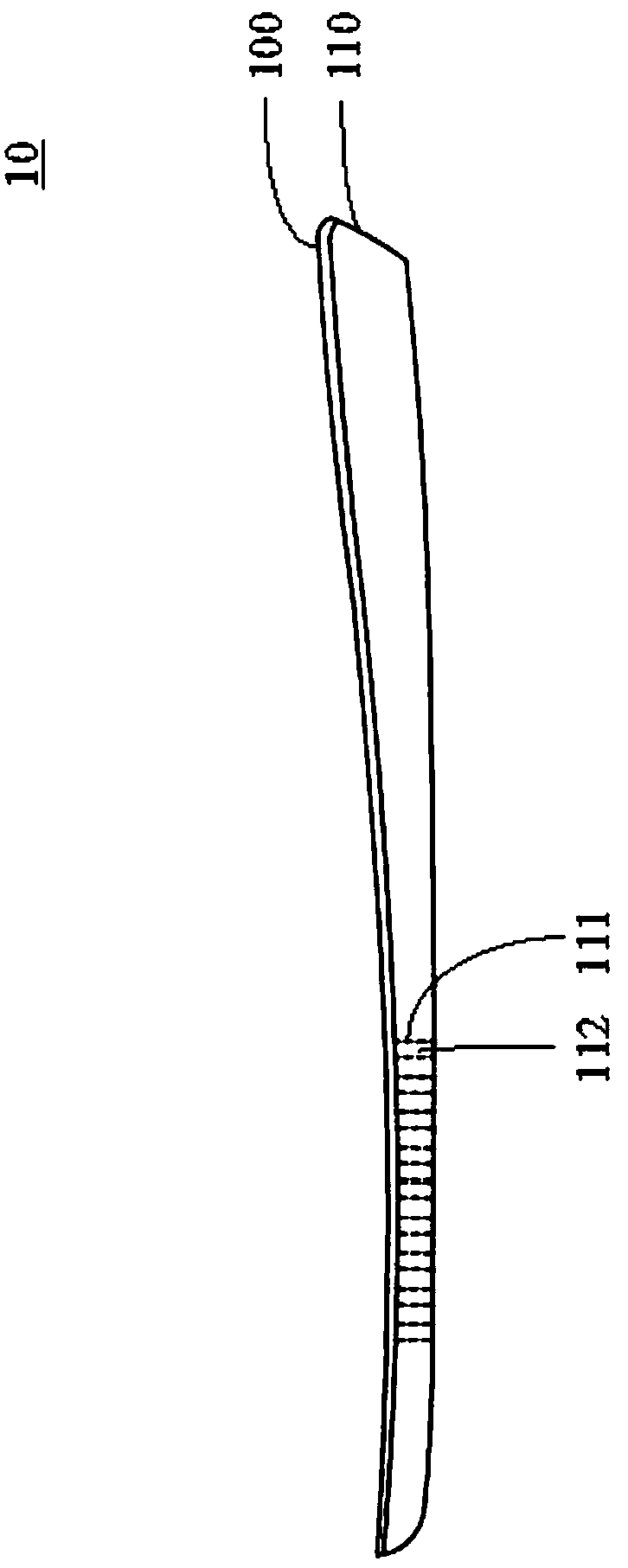

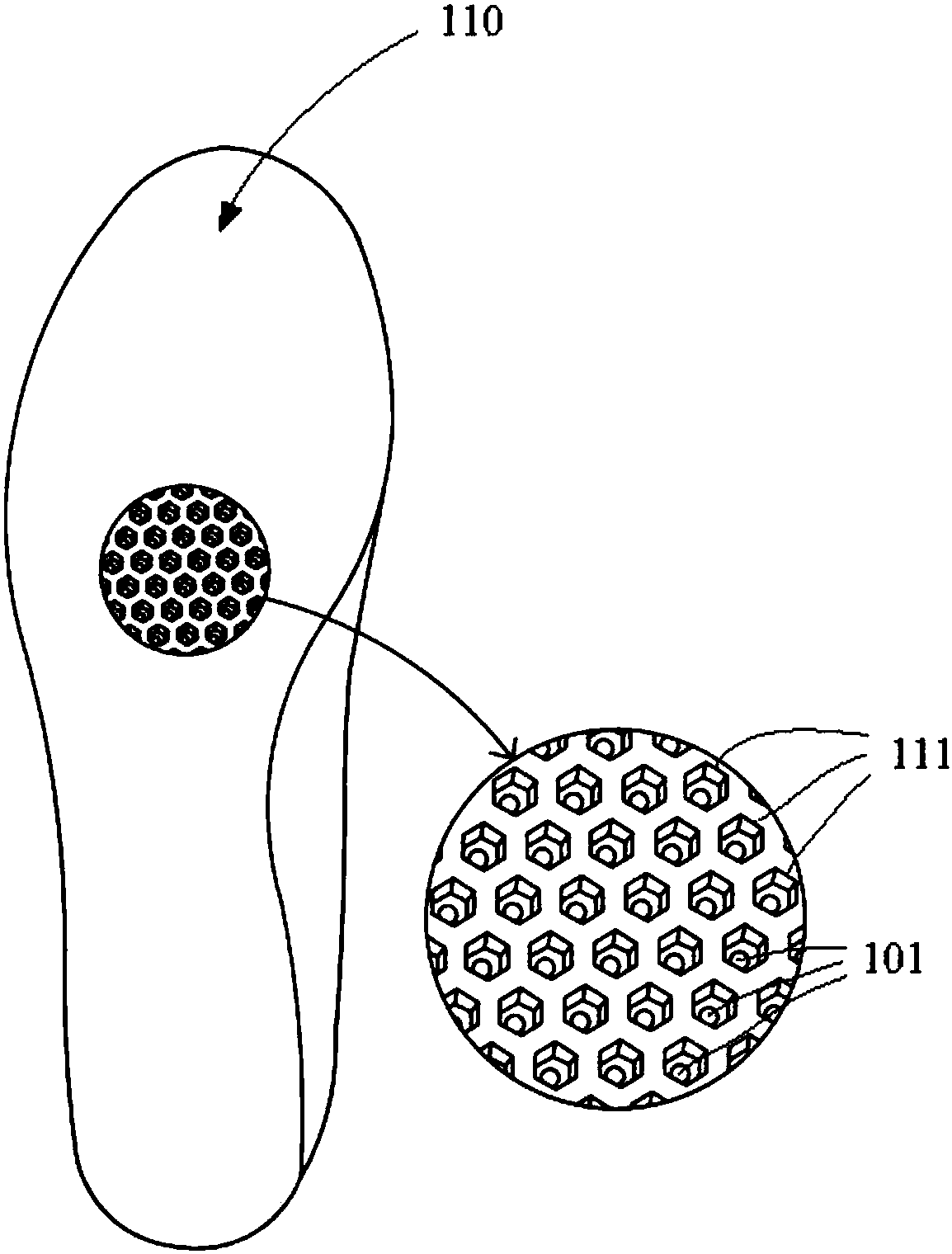

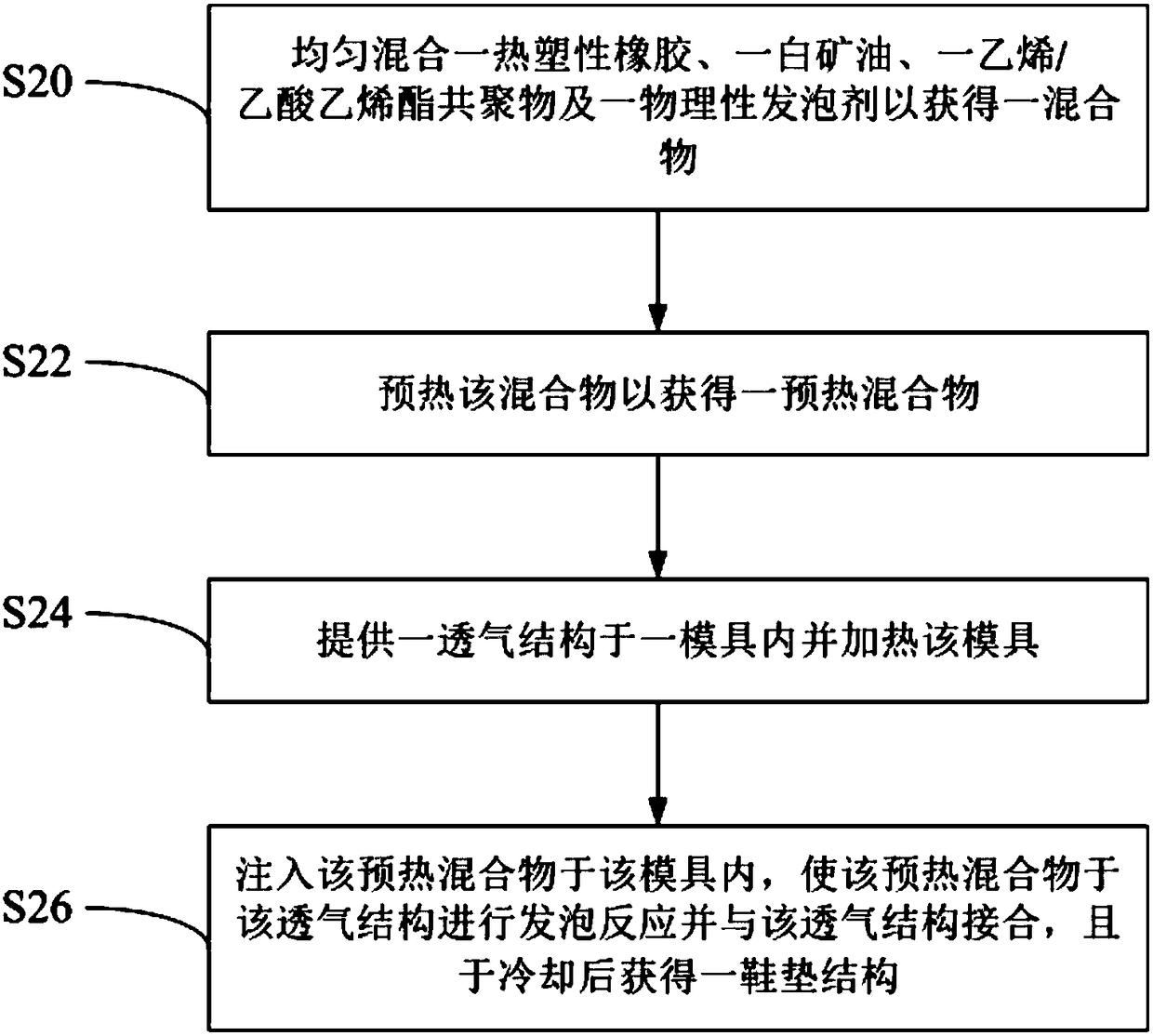

[0032] In order to make the structural features of the present invention and the achieved effects have a further understanding and recognition, preferred embodiments and detailed descriptions are specially used, which are described as follows:

[0033] This implementation case provides an insole composition, an insole structure, and a manufacturing method for an insole structure, which are based on conventional fabrics and elastic structural layers, and need to pass through substances with adhesive properties (such as: Viscose) are joined together, so that the fabric and the elastic structure layer are blocked by the adhesive material, causing the heat and sweat generated by the soles of the feet to be unable to be removed, thus causing discomfort or odor when the user walks in the shoes; for To solve the above-mentioned shortcoming of the prior art, the present embodiment then proposes an insole composition, an insole structure and a manufacturing method thereof, which will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com