Steam boiler and steam boiler set

A steam boiler and pot body technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of low overall stability, easy shaking, poor safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

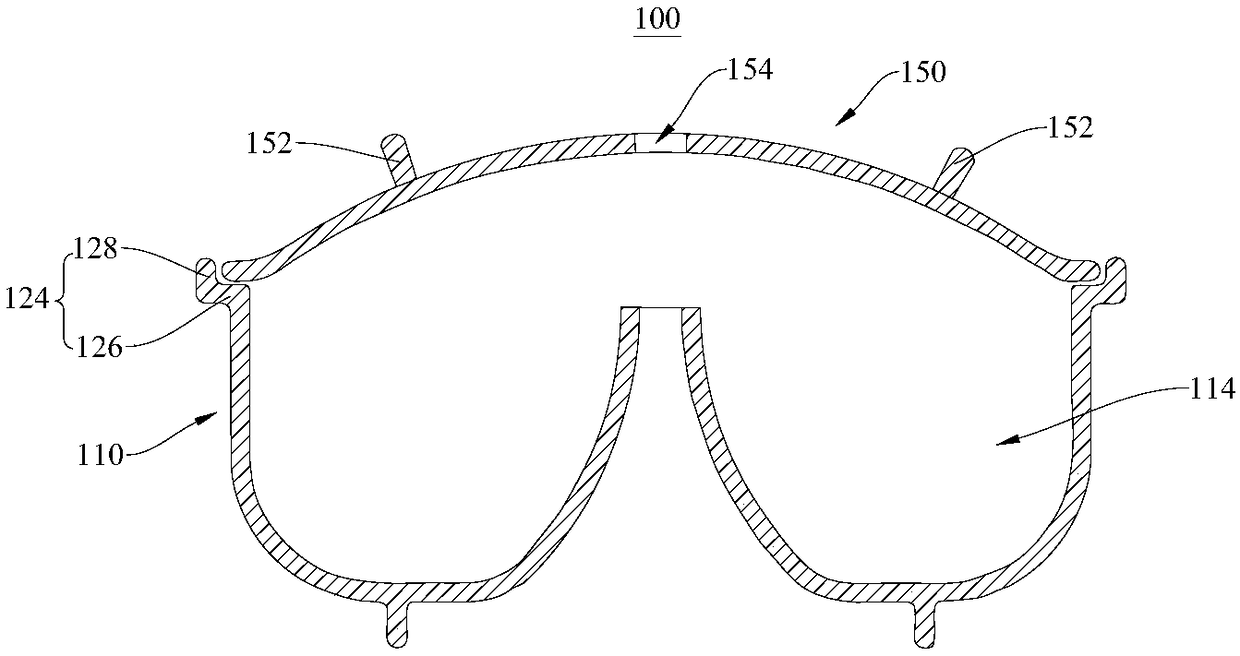

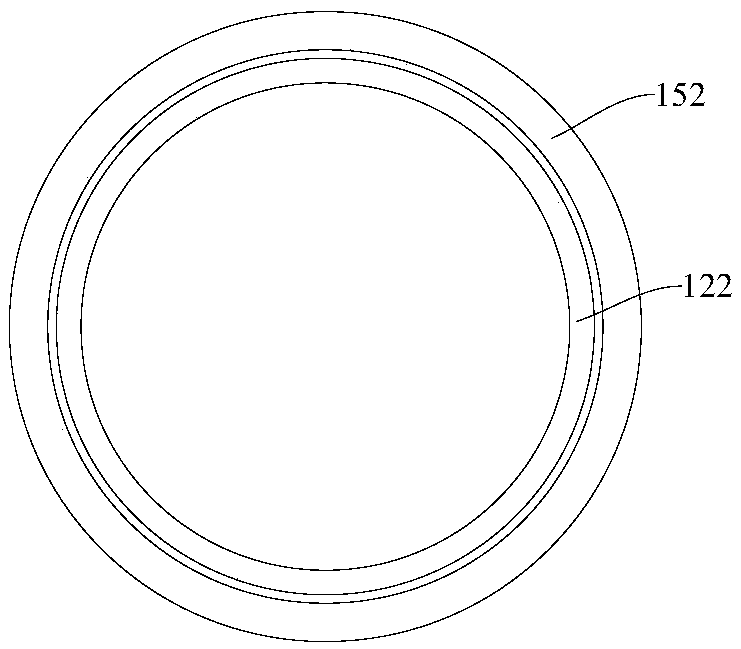

[0038] Please refer to figure 1 , figure 1Shown is a schematic structural view of the boiler 100 . This embodiment provides a steam boiler 100, which can be mainly used as a cooker for steaming.

[0039] The boiler 100 mainly includes a boiler body 110 and a boiler cover 150 that match each other. The pot body 110 is used to hold the ingredients, and the pot cover 150 can be placed on the pot body 110, so that the ingredients in the pot body 110 can be heated faster.

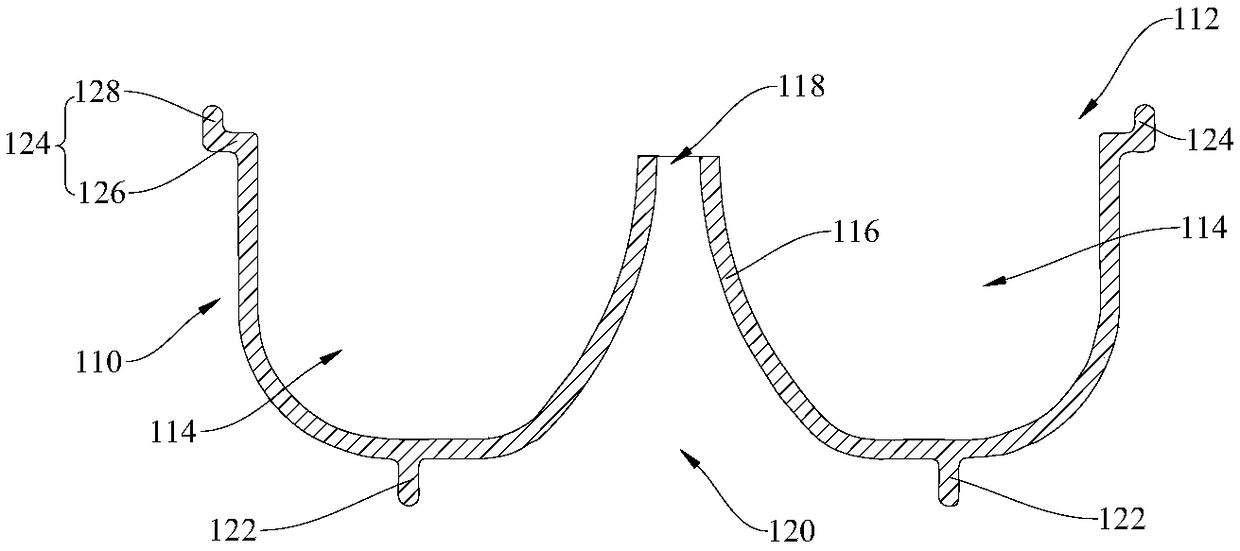

[0040] Please refer to figure 2 , figure 2 Shown is a schematic structural view of the pot body 110 . The pot body 110 is provided with an opening 112 and a steaming cavity 114 which communicate with each other. The pot lid 150 is used to open or close the opening 112 . Foodstuffs to be cooked are put into the steaming chamber 114 for steaming. The setting of the opening 112 is convenient for users to put food into the steaming cavity 114 . The pot body 110 is also provided with an air nozzle (not sho...

Embodiment 2

[0057] Please refer to Image 6 , Image 6 Shown is a schematic structural view of the boiler 200 . This embodiment provides a boiler 200, the structure of the boiler 200 is basically the same as that of the boiler 100, the difference between the two is:

[0058] The boiler 200 includes a boiler body 210 and a boiler cover 250 that match each other.

[0059] The difference between the pot body 210 and the pot body 110 is that the pot body 210 is Image 6 The tops of the shown left and right sides are not provided with the first stop portion 124 .

[0060] The difference between the pot cover 250 and the pot cover 150 is:

[0061]An air hole 252 is opened on the pot cover 250 . In this embodiment, the air hole 252 is not coaxially arranged with the first air guide port 118 and the second air guide port 120 (that is, the air nozzle and the air hole 252 are arranged in a misaligned position). When multiple boilers 200 overlap, take the steam source entering from the bottom ...

Embodiment 3

[0069] Please refer to Figure 7 , Figure 7 Shown is a schematic structural view of the pot cover 300 . This embodiment provides a steam boiler, which has basically the same structure as the boiler 100 , the difference between the two is that the structure of the boiler cover 300 is different from that of the boiler cover 150 .

[0070] The structure of the second limiting member 302 on the pot cover 300 is different from that of the second limiting member 152 on the pot cover 150 . The cross section of the second limiting member 302 is L-shaped, such as Figure 7 As shown, it is convenient for the user to hold the second limiting member 302 to take and place the pot cover 300 . Of course, in other embodiments, the second limiting member 302 may also be set as other structures that are convenient for the user to hold.

[0071] Where the boiler provided in this embodiment is not described in detail, reference may be made to the corresponding description in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com