Cutting tool, particularly boring bar and method for machining a plurality of bores

A technology of cutting tools and boring bars, which is applied in the field of boring bars and multiple holes, and can solve difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

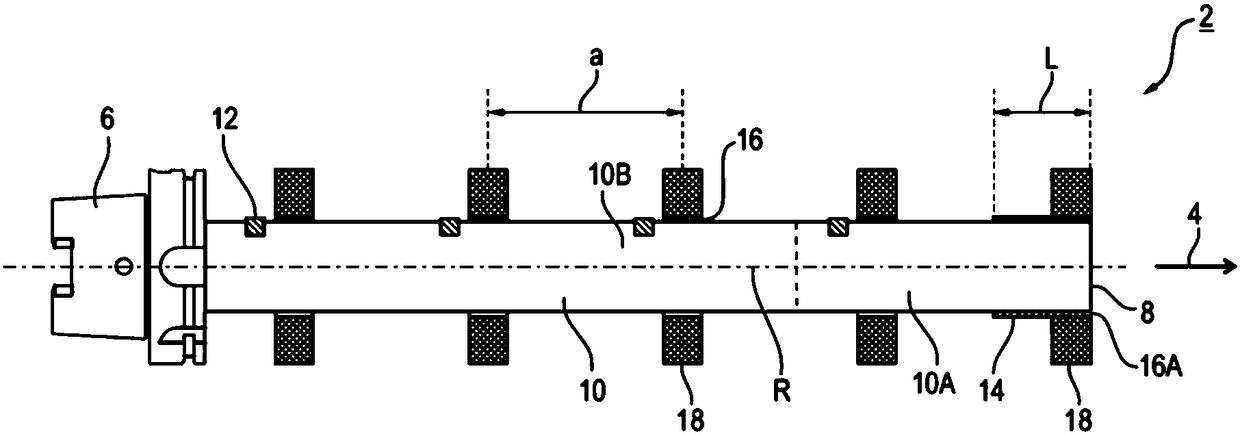

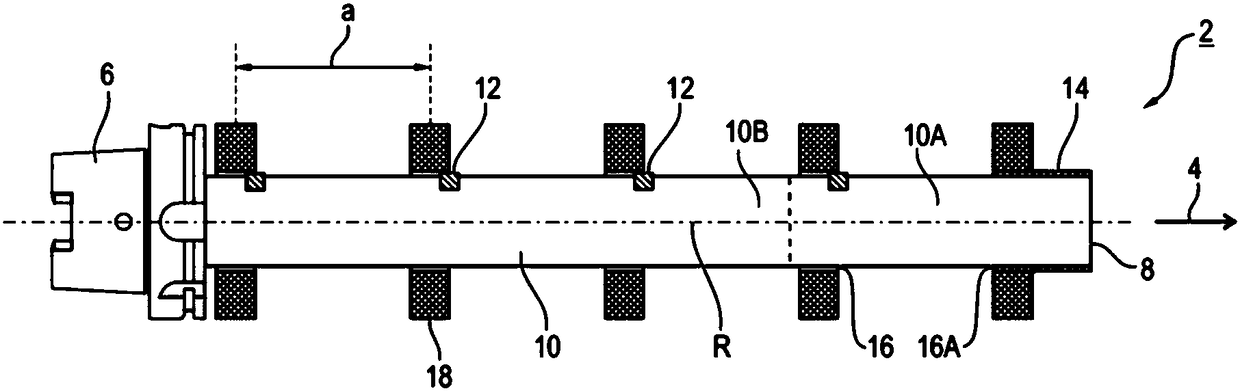

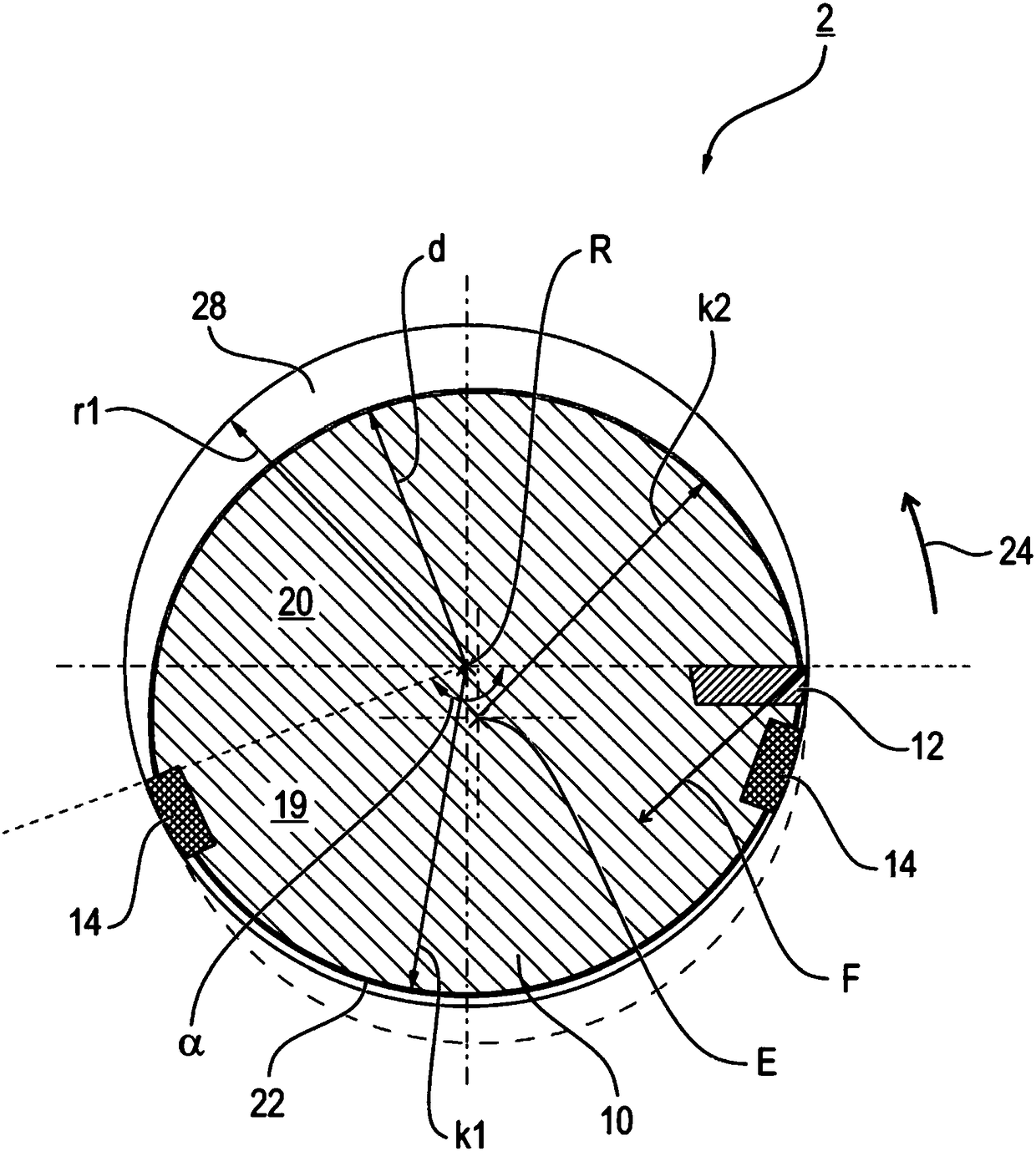

[0059] According to available from Figure 1A , 1B or Figure 5A , 5B, the two implementation variants derived from 5C, the boring bar 2 also configured as a tandem boring bar extends in the axial direction 4 from the rear adapter 6 to the front end side 8 . The boring bar 2 next to the adapter 6 has a rod-shaped base body 10 , on which cutting elements 12 spaced apart from one another in the axial direction are fastened in respective working positions on the base body 10 . All cutting elements 12 are arranged here on the base body 10 at the same angular position and thus lie on a line. Only one cutting element 12 is arranged on the base body 10 for each working position. Furthermore, a guide element 14 designed in the form of a guide plate is arranged on the base body at the guide point of the base body 10 . The cutting element 12 as well as the guide element 14 form a functional element.

[0060] As an alternative to the illustrated solution in which the cutting elements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com