Multi-laser fusion type processing method

A processing method and laser technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency, difficult equipment maintenance, complicated procedures, etc., achieve accurate time estimation, save light source costs, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention discloses a variety of laser fusion processing methods. The specific implementation manners of the present invention will be further described below in combination with preferred embodiments.

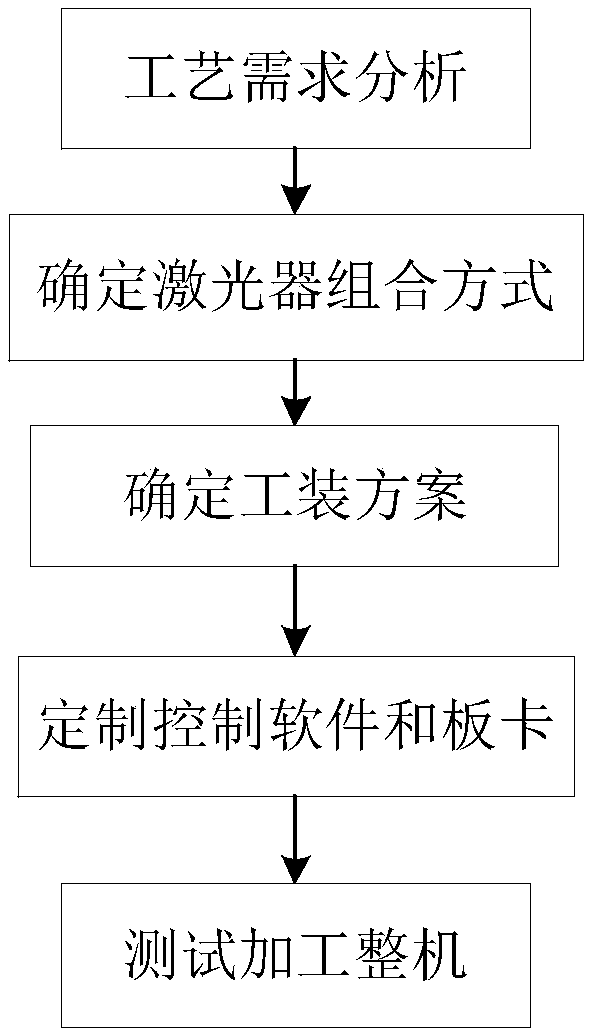

[0021] see attached figure 1 , figure 1 The related flow of the various laser fusion processing methods is shown. Preferably, the multiple laser fusion processing methods include the following steps:

[0022] Step S1: Analyze the technological requirements of the processing object;

[0023] Step S2: Select the combination of lasers according to the process requirements to meet the processing requirements of different processes;

[0024] Step S3: Determine the tooling scheme according to the actuators required during the process;

[0025] Step S4: Customize control software and boards according to the type of laser processing required by the processing object.

[0026] Further, step S2 further includes step S2.1:

[0027] Step S2.1: Design the structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com