Lifting appliance device for installing wind-turbine blades, and operation method

A wind turbine and blade technology, applied in the field of wind turbine blade hoisting, can solve the problems of not being very safe and reliable, reducing the efficiency of hoisting work, not being very reliable, etc., and achieving the effects of strong adaptability to the environment, large torque, and low torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific implementation plan

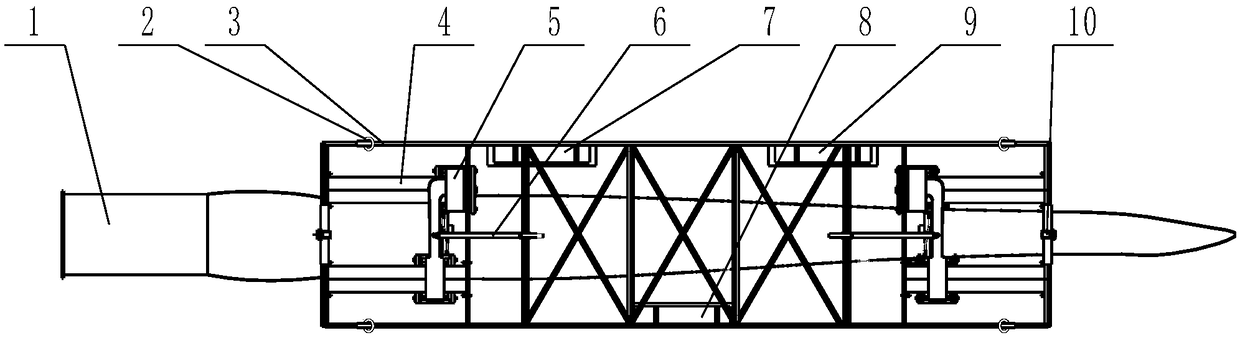

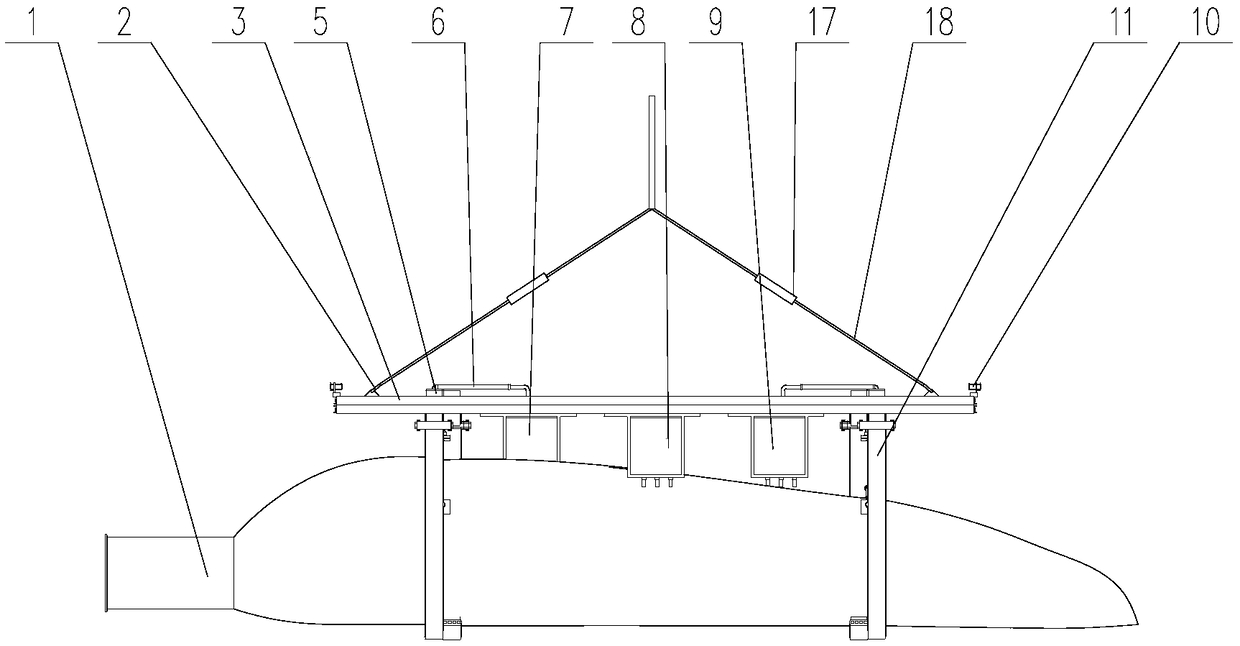

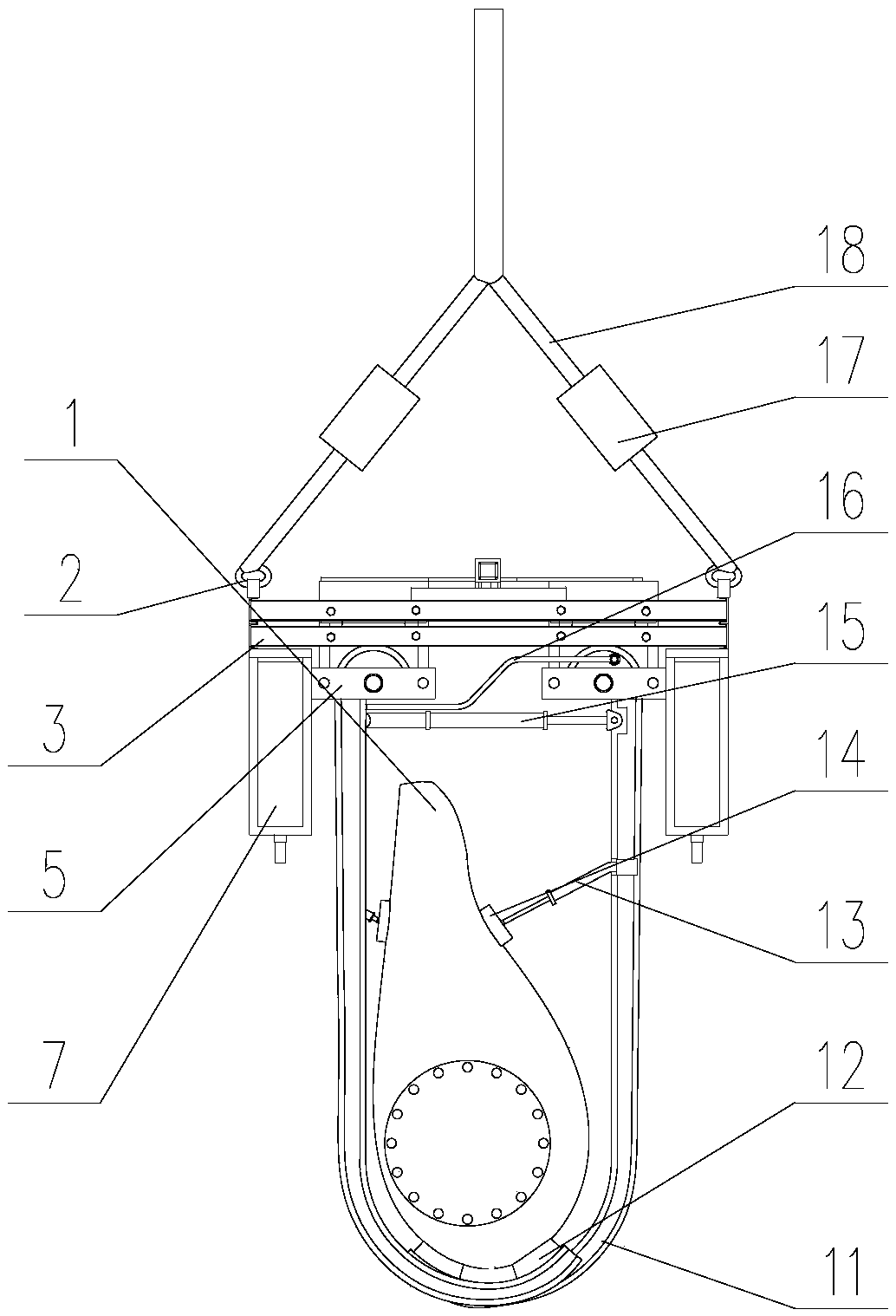

[0030] Attached figure 1 , 2 , 3, a spreader device for installing wind turbine blades 1, the main beam hanger 3 is welded with double-layer channel steel, and four corners of the hanger are installed with lifting rings 2 to provide lifting points for the spreader . At both ends of the main beam hanger 3 in the longitudinal direction, lighting lamps 10 are installed. In the middle position of the main beam hanger 3 in the longitudinal direction, in order to ensure the strength of the main beam hanger 3, a plurality of back-to-back channel steels are welded as beams , The diagonal beams between every two beams are welded with channel steel to further strengthen the strength of the main beam hanger 3. Horizontal walking mechanisms are respectively installed at both ends of the main beam hanger 3 in the length direction. The horizontal walking mechanism includes a wedge-shaped guide rail 4 with a stroke of 2m, two parallel guide rails 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com