Quick-mounting device and mounting method thereof

An installation method, square technology, applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problem of maintenance or replacement after more than 15 years, limited service life of chemical planting bars or expansion bolts, and failure to reach the durability of subways Requirements and other issues, achieve the effect of unifying the installation of fixed bolts and nuts, reducing operation and maintenance costs, and reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments disclosed in the present invention will be further described in detail below in conjunction with the accompanying drawings.

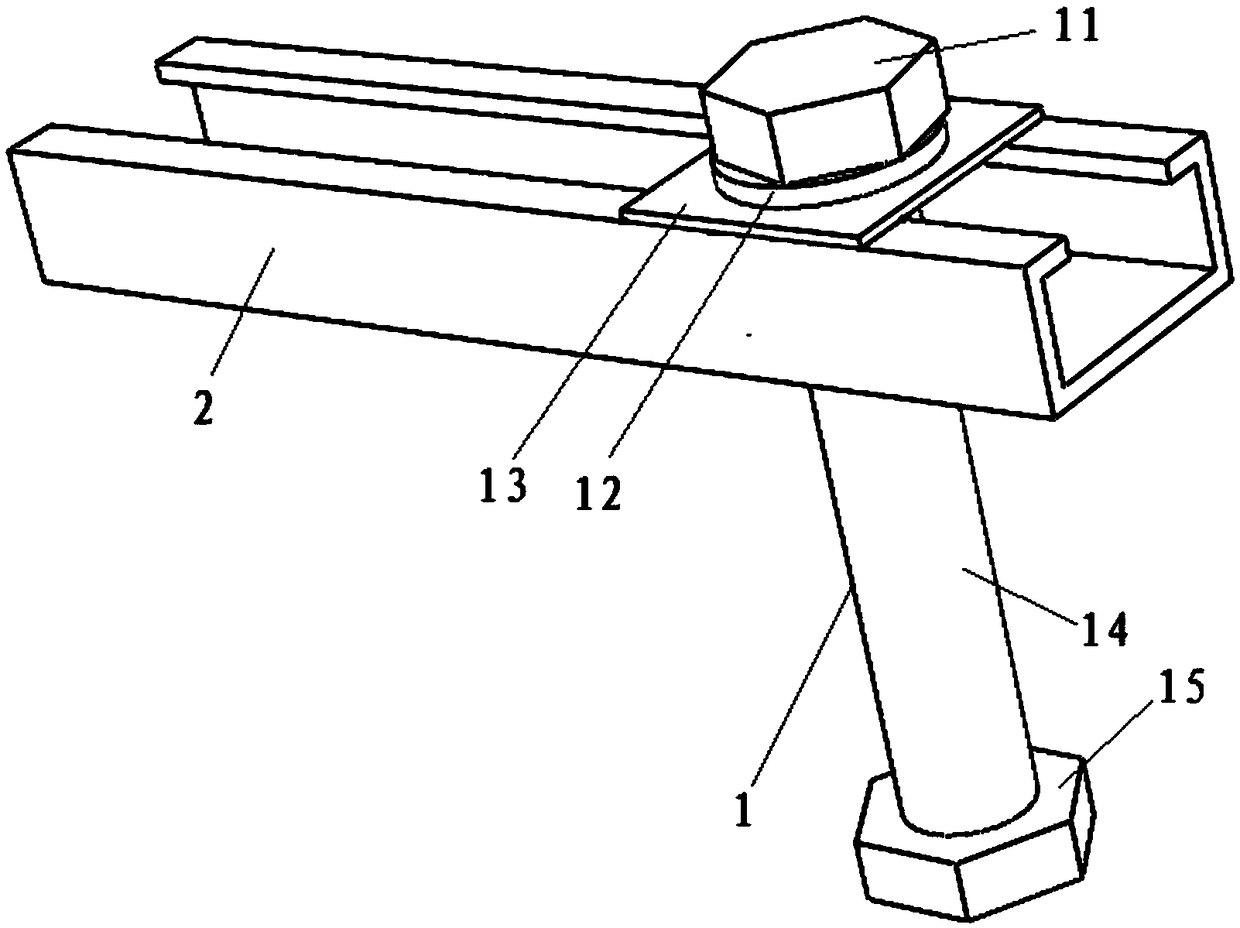

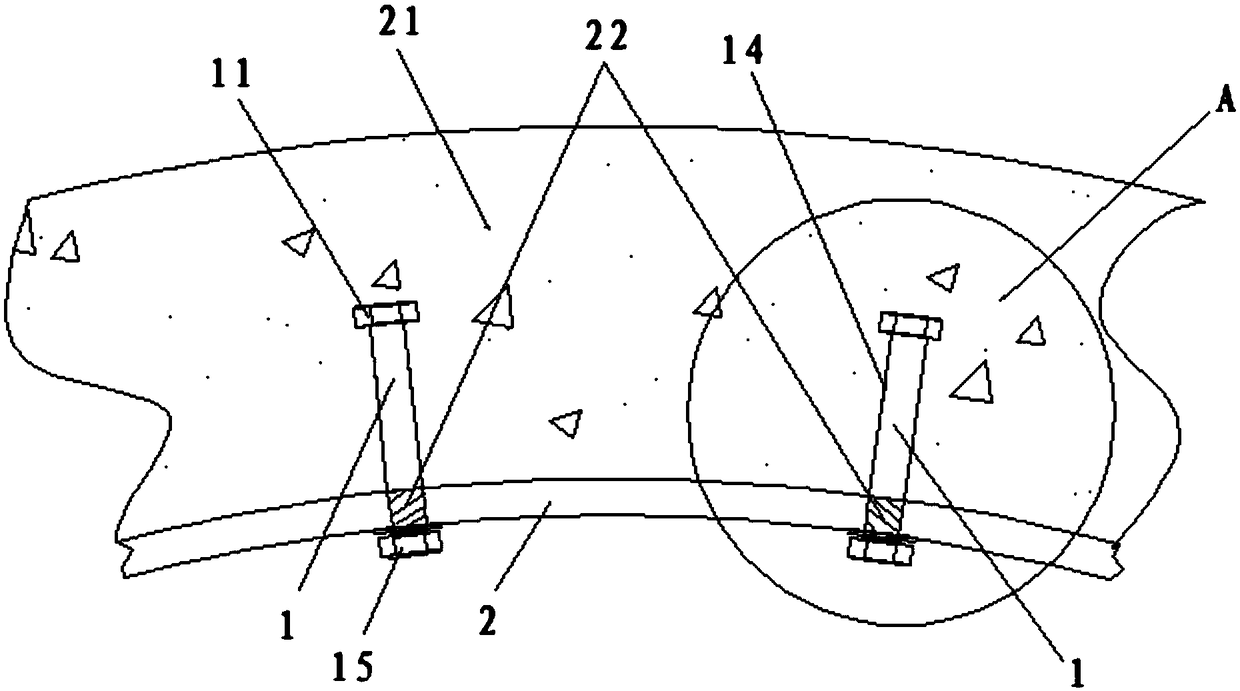

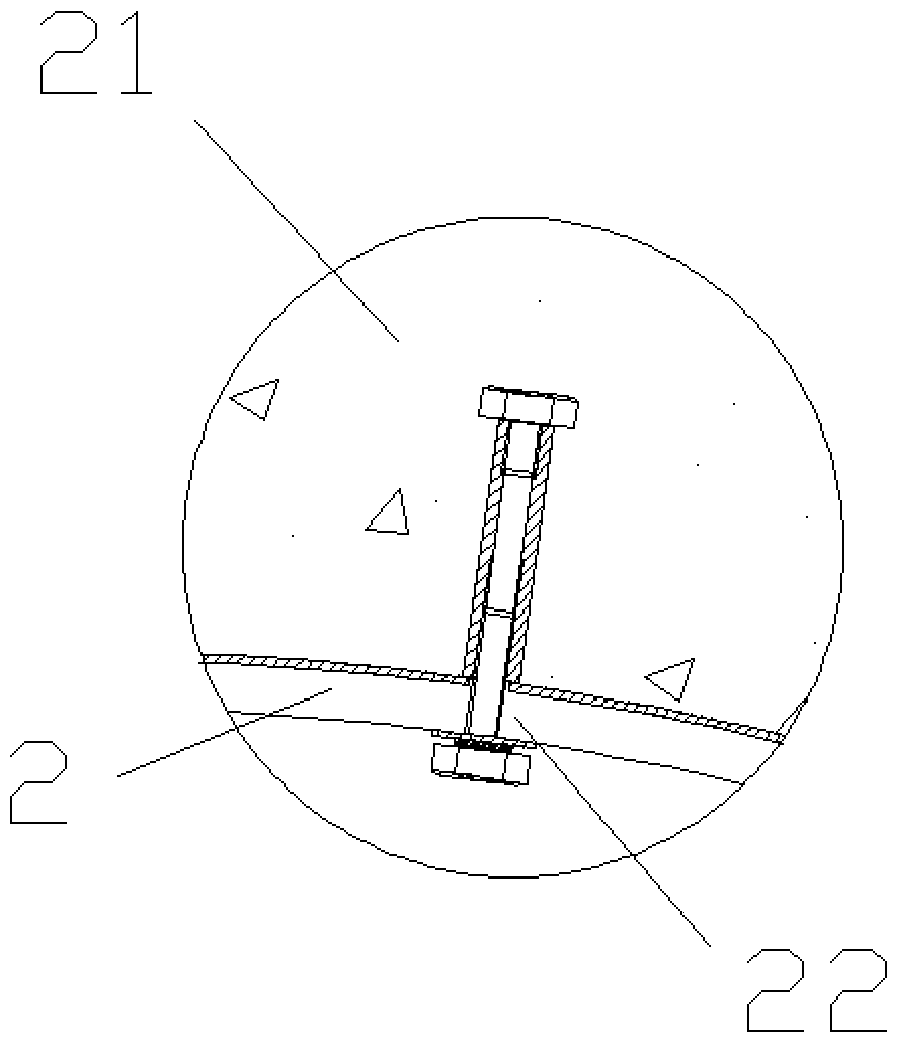

[0035] The invention discloses a quick-installation device, which belongs to a quick-installation scheme for installing electromechanical equipment and pipelines in subway tunnels. The quick-installation device comprises: a pre-embedded sleeve and an external channel. Among them, one end of the pre-embedded sleeve is screwed into the steel pipe with internal thread with a connecting bolt, and then pre-cast into the shield segment, and the other end is attached to the surface of the shield segment. The pre-embedded sleeve attached to the surface of the shield segment has internal threads, and the combination of fastening bolts, spring washers and square gaskets passes through the fastening bolt holes set on the external channel to ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com