Real-time coal density measuring system and method

A real-time measurement and density technology, applied in the field of coal chemical industry, can solve the problems of large randomness of measurement data, large labor time consumption, low measurement accuracy, etc., and achieve the effect of reasonable planning of resources, low cost input, and accurate measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

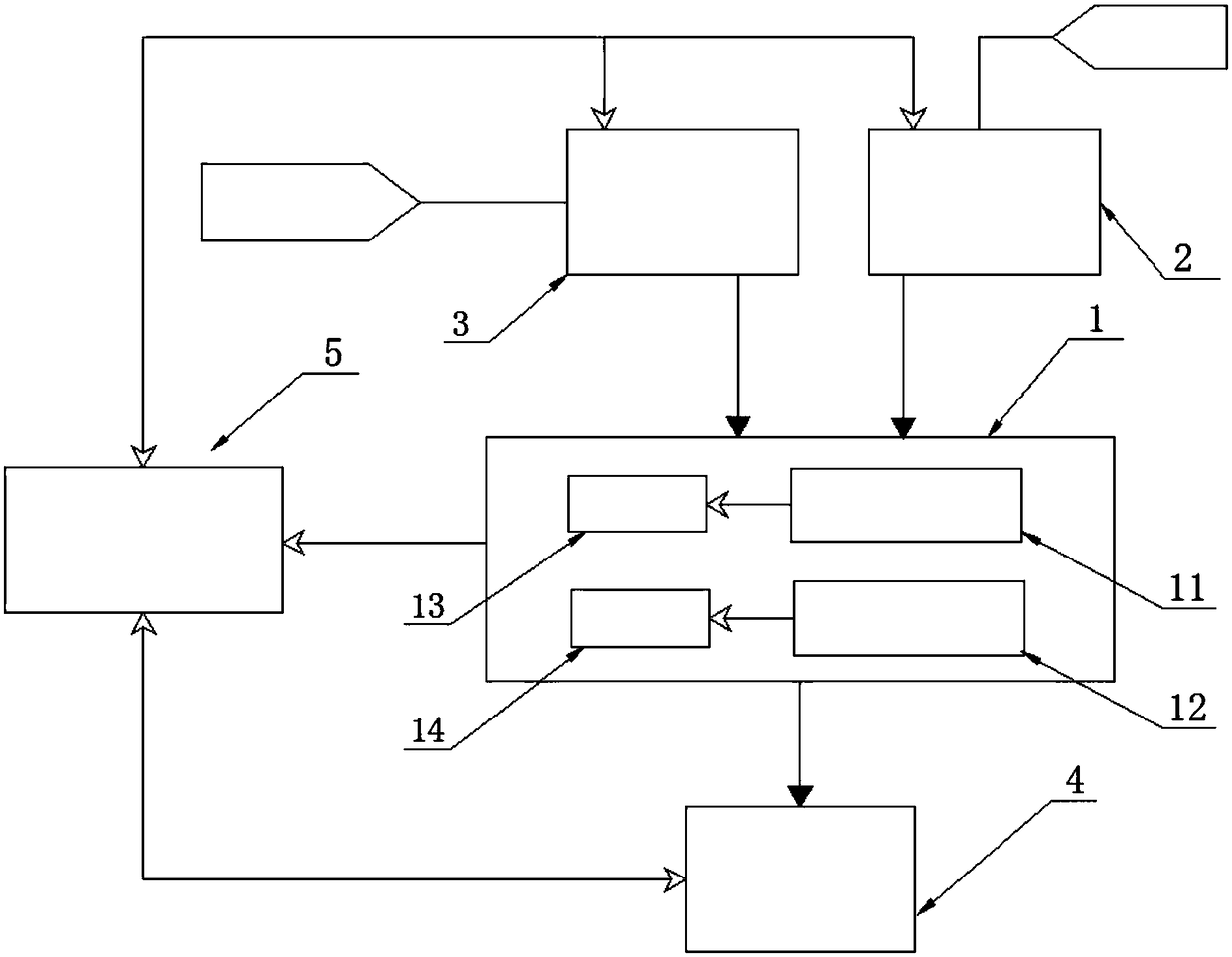

[0034] see figure 1 , The coal density real-time measurement system of the present invention includes a weighing unit 1, a water supply unit 2, a sampler 3, a slag discharge unit 4 and an automatic controller 5. Described weighing unit 1 comprises main weighing tank 11, overflow weighing tank 12, main weighing sensor 13 and overflow weighing sensor 14, the top of described main weighing tank 11 and described overflow weighing tank 12 connected, the main weighing sensor 13 and the overflow weighing sensor 14 are respectively arranged under the main weighing tank 11 and the overflow weighing tank 12; the water supplement unit 2 and the sampler 3 are arranged on the main Next to the weighing tank 11, it is used to add water and coal samples to the main weighing tank respectively; and water; the automatic controller 5 is connected with the weighing unit 1, the water replenishment unit 2, the sampler 3 and the slag discharge unit 4, and the automatic controller 5 can connect the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com