Automatic coal density testing system and method

A density and automatic technology, applied in the field of coal chemical industry, can solve the problems of high labor time consumption, low measurement accuracy, difficult sampling, etc., and achieve the effect of low cost investment, accurate measurement data, convenient and accurate cost investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

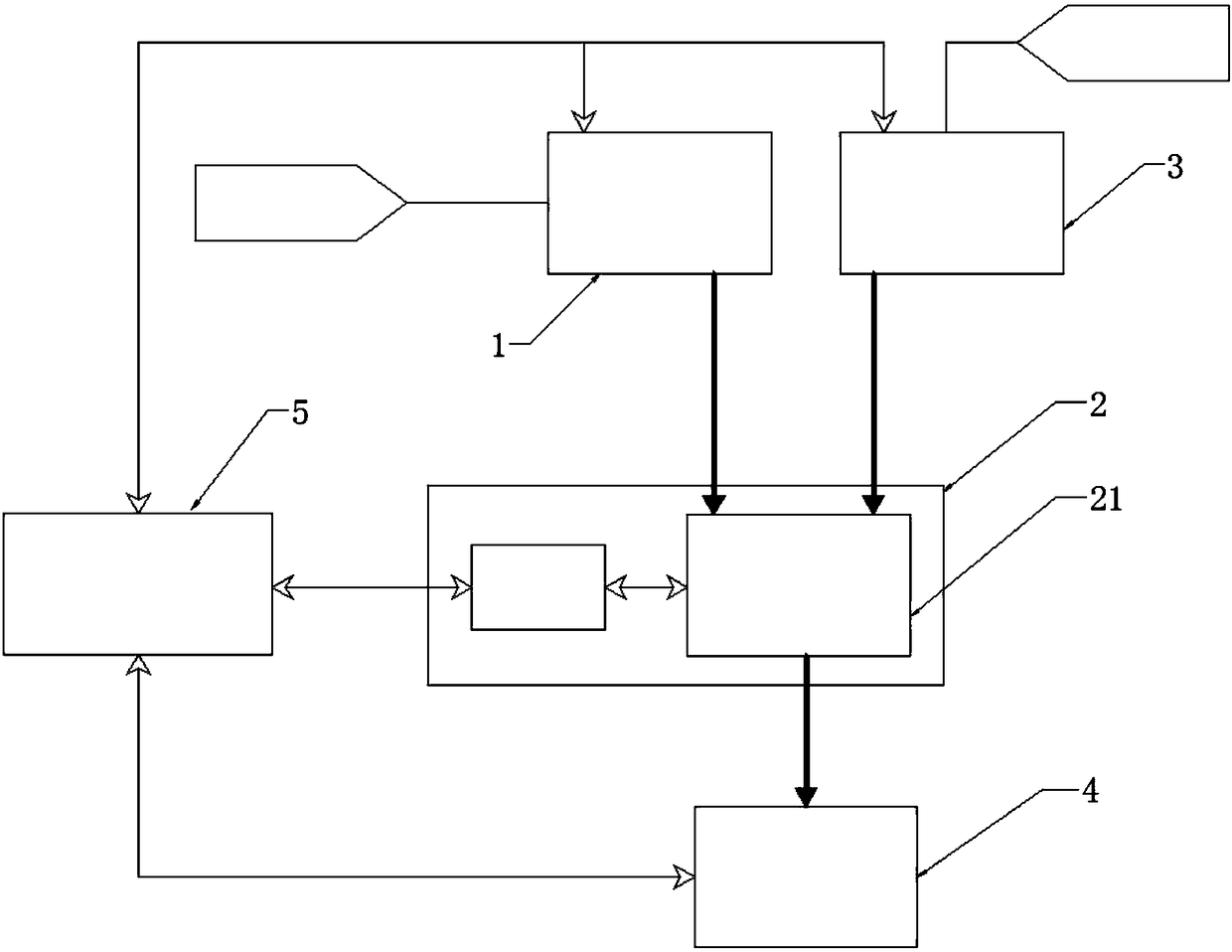

[0025] see figure 1 , The automatic coal density determination system of the present invention includes a sampler 1, a metering unit 2, a water supply unit 3, a discharge unit 4 and an automatic controller 5. The sampler 1 and the replenishment unit 3 are arranged beside the metering unit 2 and are respectively used for adding coal samples and replenishing water to the metering unit 2, and the unloading unit 4 is arranged on one side of the metering unit 2 And it is used for discharging the coal sample and water in the metering unit 2 . The automatic controller 5 is connected with the signal of the sampler 1, the metering unit 2, the water replenishment unit 3 and the unloading unit 4, and the automatic controller 5 automatically controls the sampler 1, the metering unit 2, the water replenishment unit 3 and the unloading unit 4 Actions.

[0026] Specifically, the sampler 1 in this embodiment is a sampling manipulator, and the sampler can also be set as a rotary sampler.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com