Rotary wastewater filtering device capable of automatically discharging residues

A technology of automatic slag discharge and filtration device, applied in the direction of mobile filter element filter, filtration loop, filtration and separation, etc., can solve the problems of resource consumption, increase production cost of enterprises, delay enterprise time, etc., to save enterprise cost and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

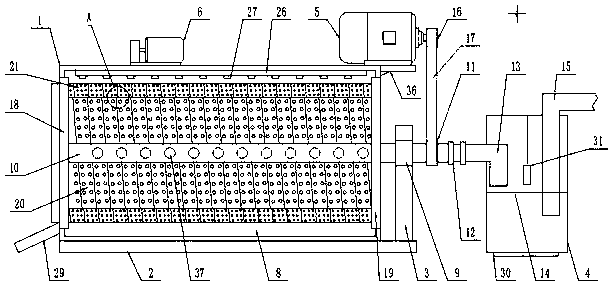

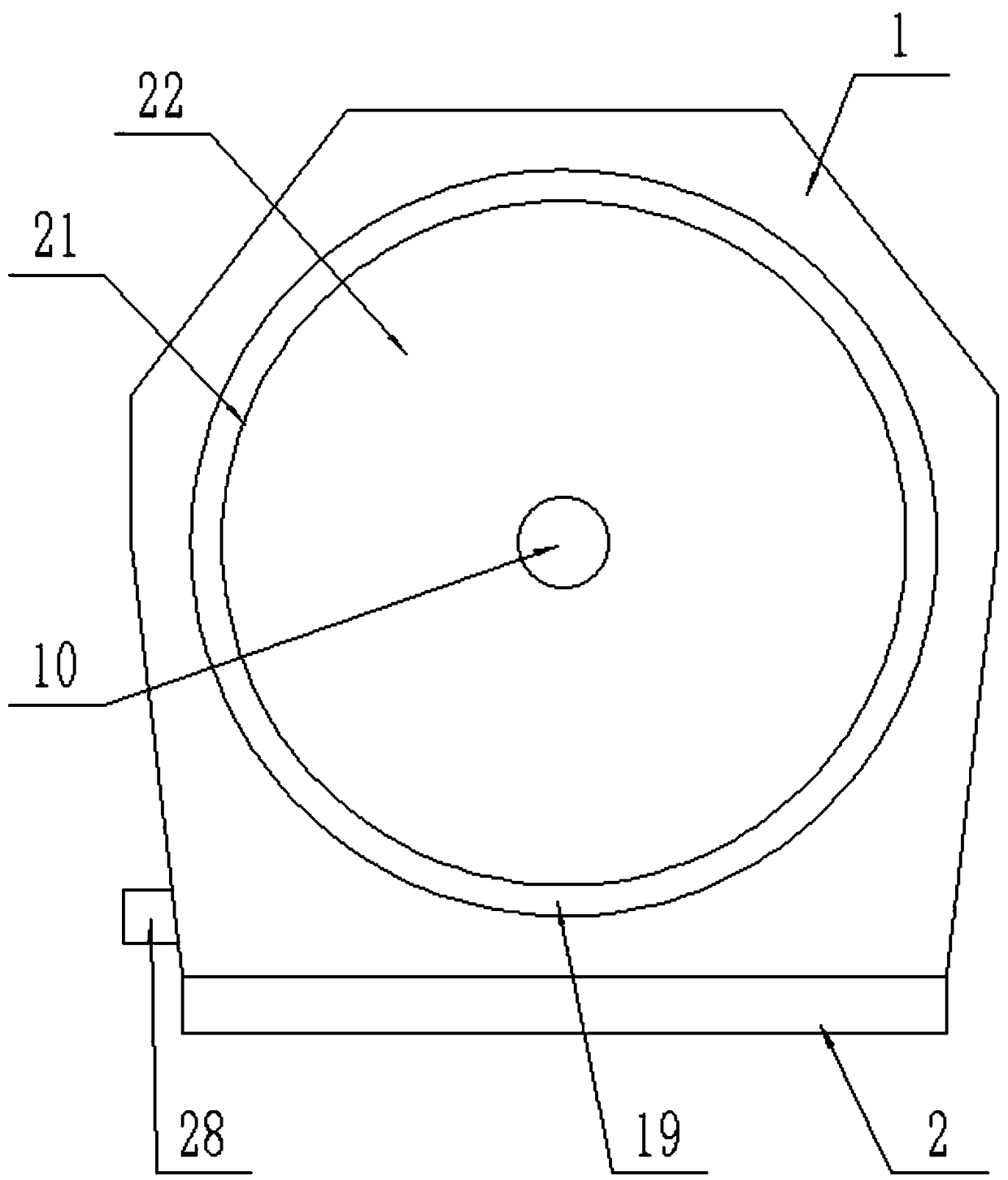

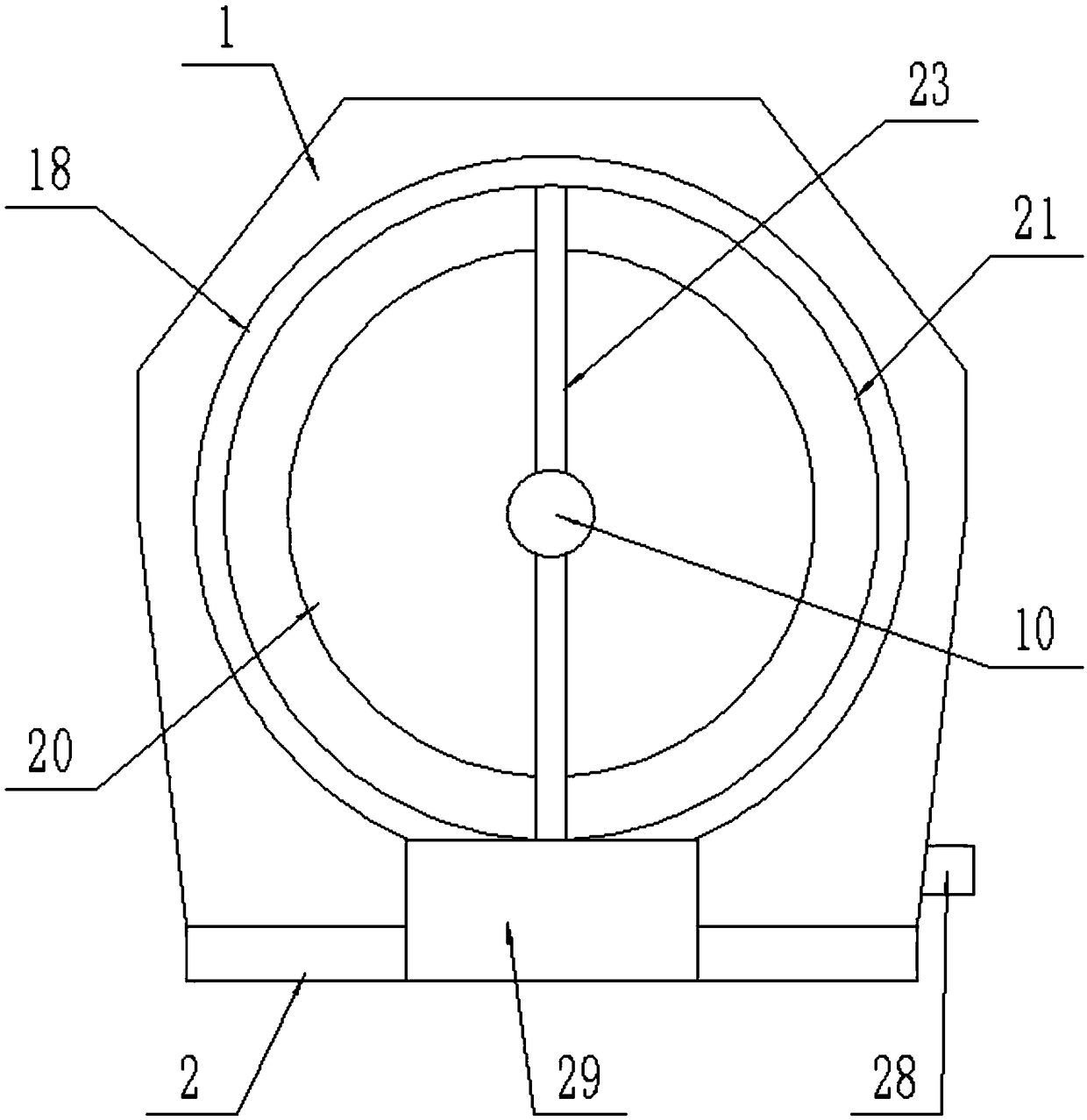

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a rotary waste water filter device capable of automatic slag discharge includes a filter box body 1, a base 2, a bracket 3, a sedimentation tank 4, a frequency conversion motor 5, a water pump 6 and a controller 7, and the filter box body 1 is installed On the base 2, the filter box body 1 is provided with a filter cavity 8, the bracket 3 is fixed on the right side of the filter box body 1, the bracket 3 is an H-shaped bracket 3, and the center of the beam at the upper end of the bracket 3 A ball bearing 9 is embedded in the center, and the ball bearing 9 is inserted with a hollow shaft 10 extending into the filter chamber 8. The right end of the hollow shaft 10 protrudes from the bracket 3 and is equipped with a driven pulley 11 and Rotary joint 12, the other end of the rotary joint 12 is connected with the water inlet pipe 13 communicating with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com