Adjustable jaw crushing equipment

A jaw crushing and adjustable technology, applied in the field of mining, can solve problems such as damage to the internal parts of the motor and crushing equipment, failure to crush stones well, increase production costs, etc., to avoid further damage, simple structure, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

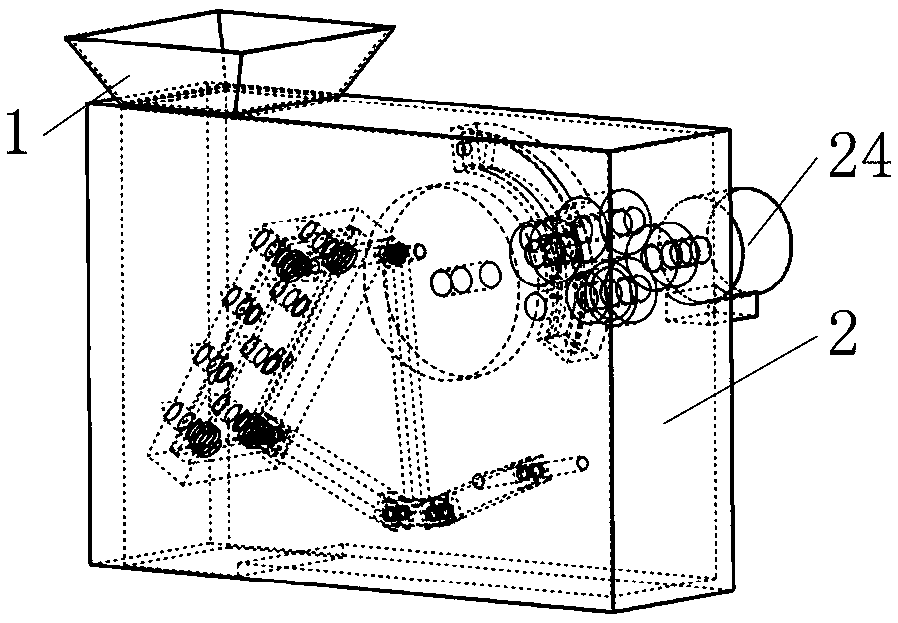

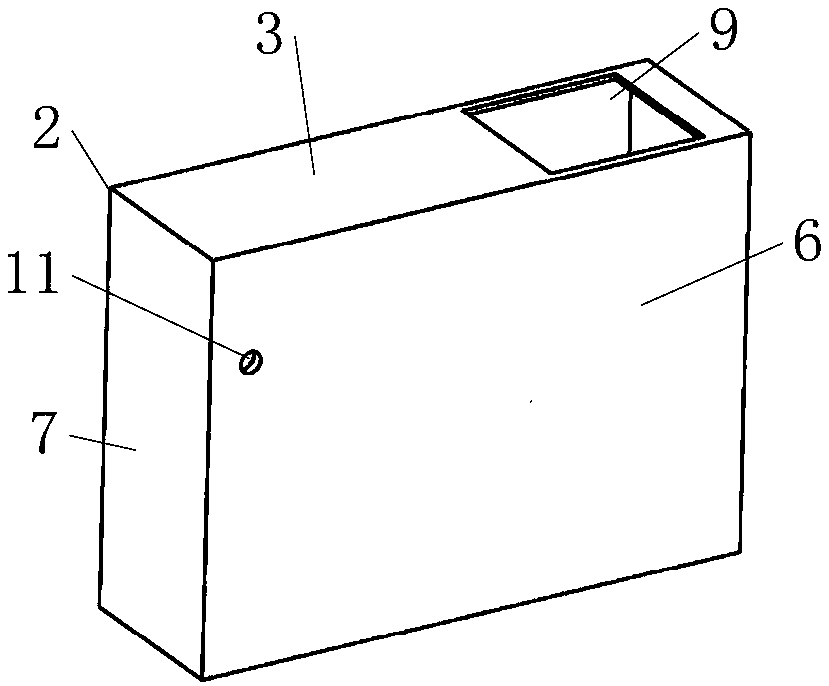

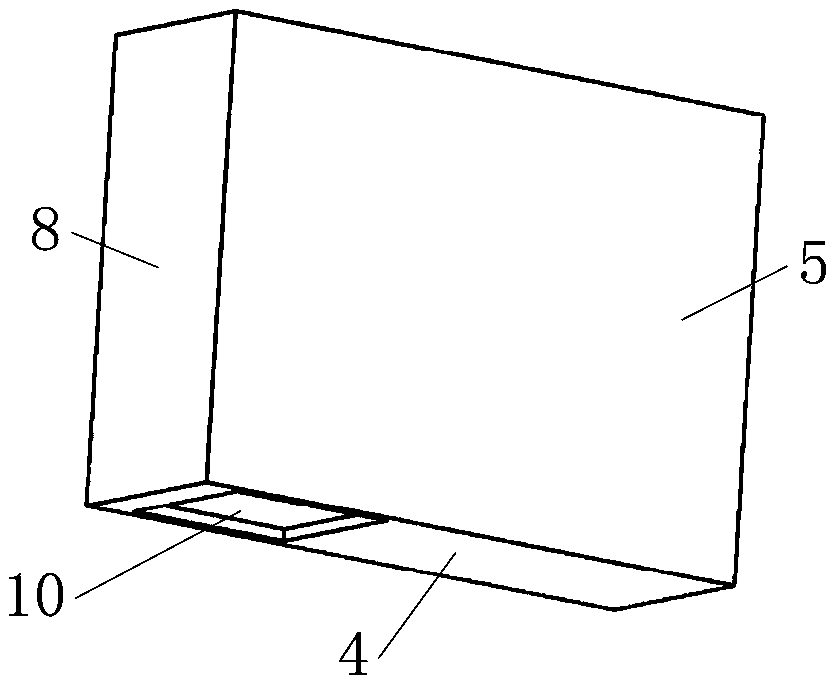

[0069] The specific embodiment: when the motor 24 starts to work, the motor 24 drives the first gear 26 to rotate; the first gear 26 drives the second gear 27, the third gear 29 and the fourth gear 28 to rotate; the second gear 27 drives the fifth gear 30 rotation; the fifth gear 30 drives the sixth gear 31 to rotate; the sixth gear 31 drives the movable jaw plate 63 to swing around the fifth shaft 18 through the first pull rod 33, the second pull rod 35 and the third pull rod 36; the general material crushing process , when the angle between the movable jaw 63 and the fixed jaw 8 becomes larger, the movable jaw 63 gradually approaches the fixed jaw 8; the movable jaw 63 and the fixed jaw 8 squeeze the material, thereby breaking the material; When the angle between the movable jaw plate 63 and the fixed jaw plate 8 becomes small, the movable jaw plate 63 will separate from the fixed jaw plate 8, and the crushed material will fall to the discharge port 10; When a larger or hard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com