A composite guide plate with surface spray coating

A technology of surface spraying and guide plate, applied in the field of composite guide plate, can solve the problems of lack of effective means and materials, and achieve the effect of simple preparation process, easy replacement and maintenance, and prevention of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

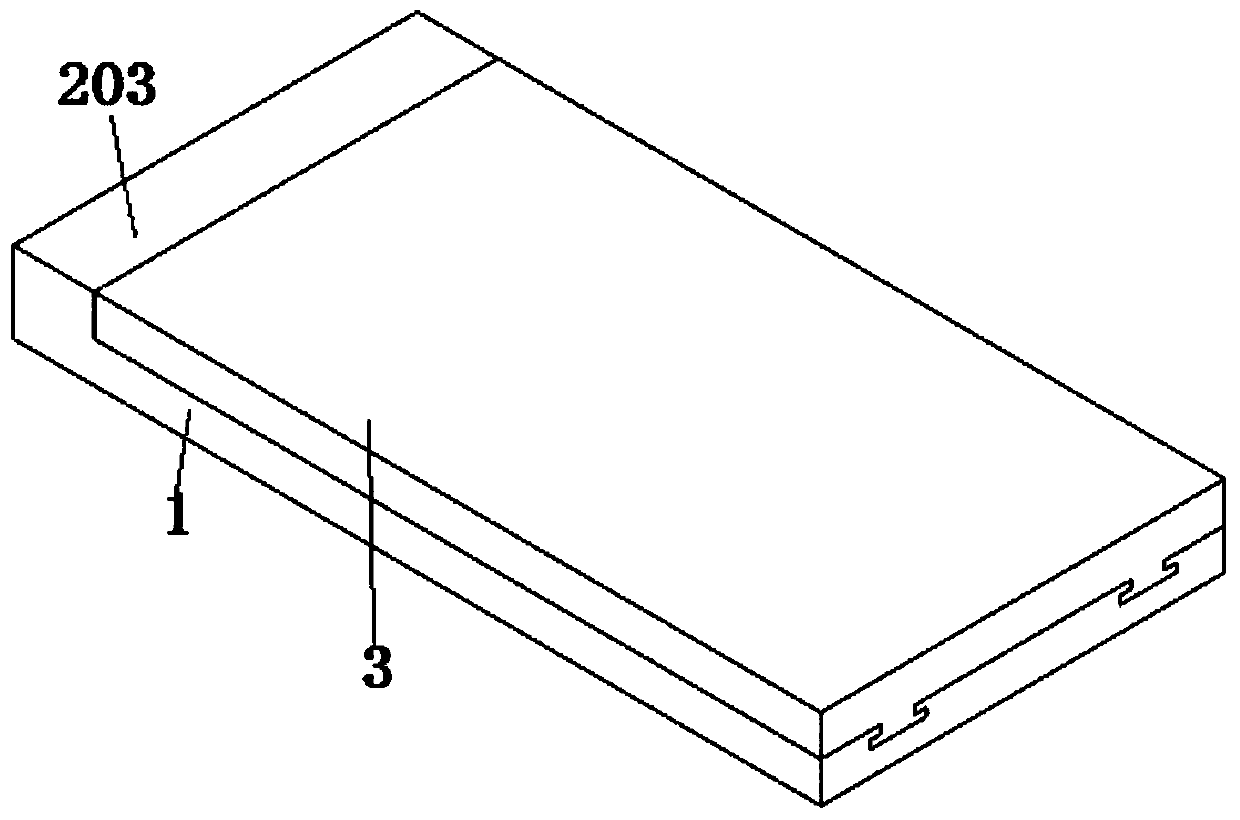

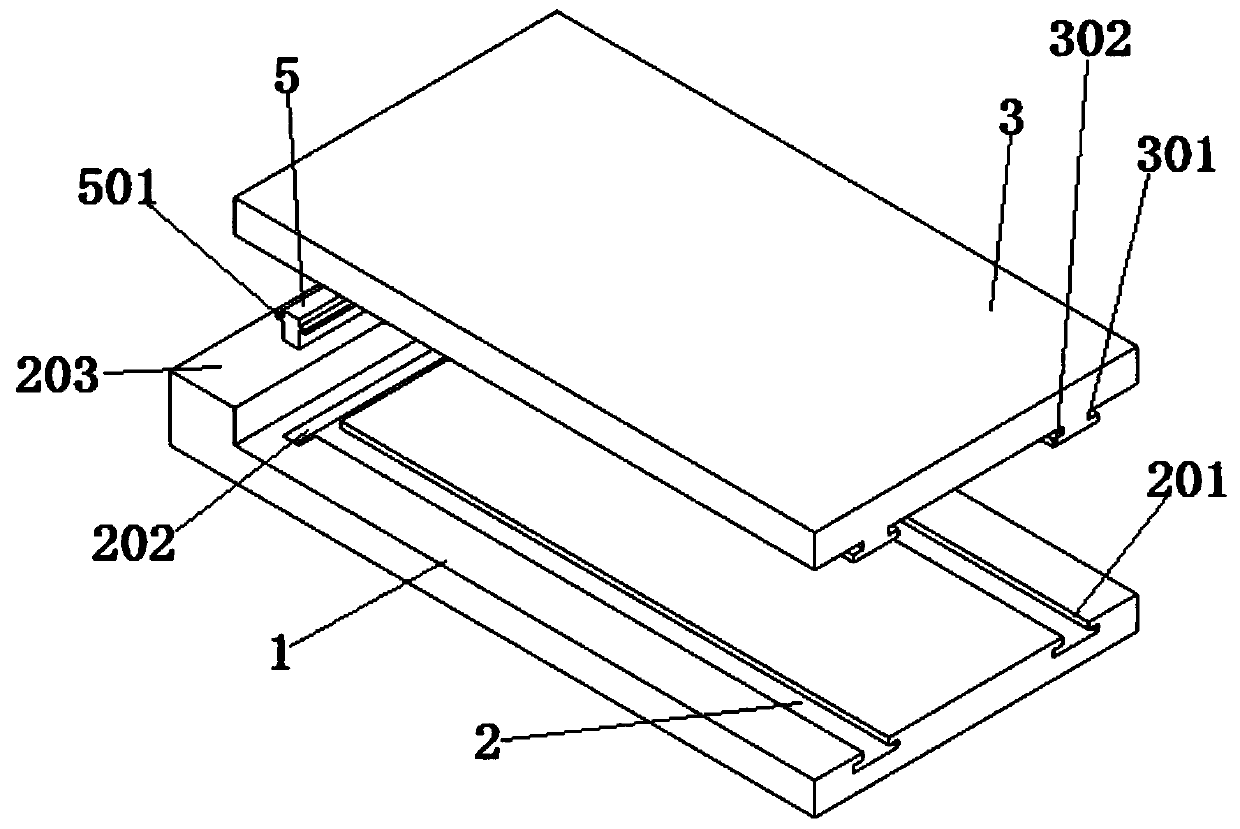

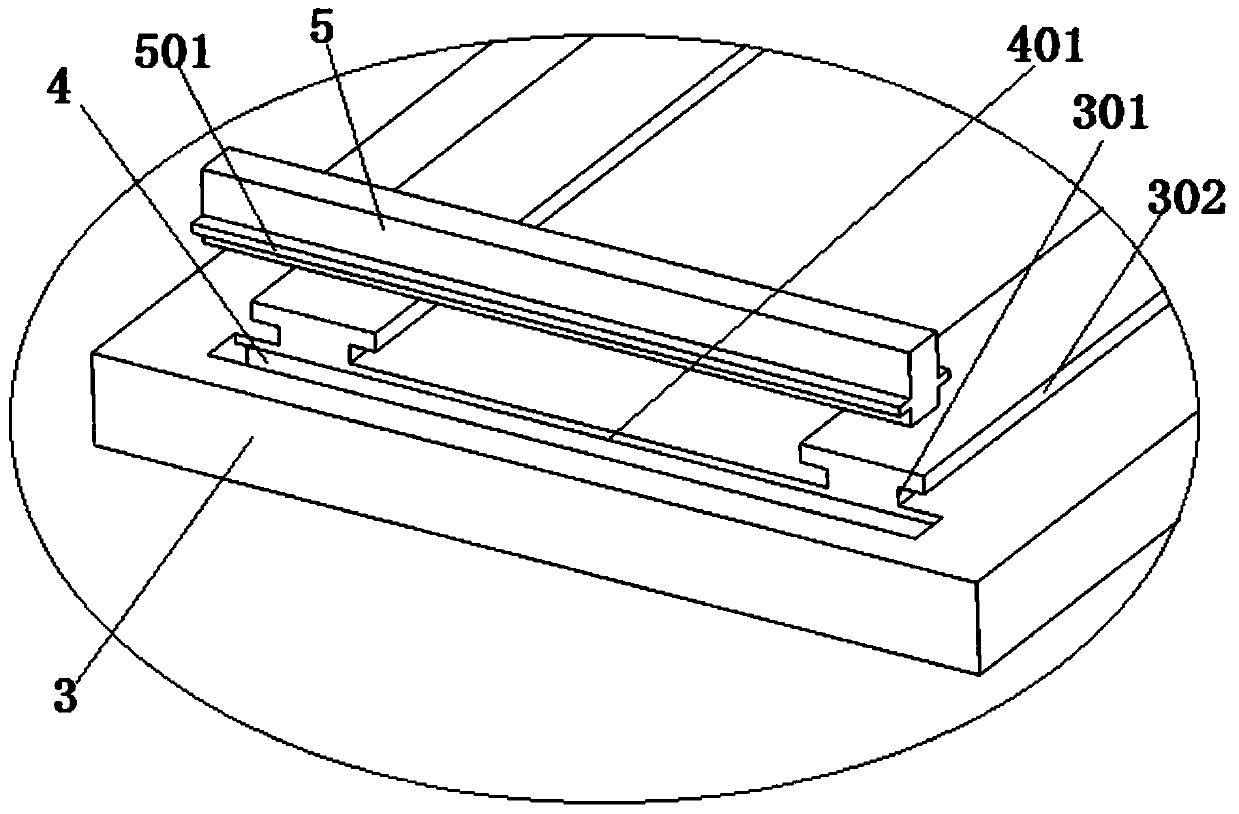

[0028] Such as Figure 1-3 As shown, a composite guide plate with a surface sprayed coating includes a guide plate, and a plurality of first chute 2s are provided at the working joint surface 1 on the guide plate, and the upper end of the first chute 2 is also A first limit slot 201 is provided, and a card slot 202 is provided at the front end of the first chute 2, and a first stop block 203 is provided at the front end of the card slot 202; Working block 3, the lower end of the working block 3 is also fixed with a number of connecting blocks 301, and the lower end of the connecting block 301 is also fixed with a first slider 302, and the first sliding block 302 cooperates with the chute 2, so The connecting block 301 cooperates with the first limiting groove 201;

[0029] The front end of the first slider 302 is provided with a first mounting groove 4, and the lower end of the first mounting groove 4 is provided with a second limiting groove 401, and the first mounting groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com