A kind of solder wire capable of welding stainless steel materials at low temperature and its preparation method

A low-temperature welding, stainless steel technology, applied in welding/cutting media/materials, welding equipment, welding media, etc., can solve problems such as excessive damage to materials, unstable low-temperature welding effect, etc., to prevent excessive corrosion, improve welding effect, inhibit The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A solder wire capable of low-temperature welding of stainless steel materials includes an external tin-based metal alloy and an internal solid active agent. The weight percentage of the tin-based metal alloy is 98.2%, and the weight percentage of the solid active agent is 1.8%.

[0038] The solid active agent is calculated by weight percentage, and its raw material composition is: highly hydrogenated rosin 30%, fluoride salt 10%, polyethanolamine 10%, organic metal salt 10%, fluoroborate 5%, fluoride ion surface activity Agent 5%, ethylene glycol 100-200 20%, castor oil thixotropic agent 5%, cetyltrimethylammonium bromide 2%, oleyl alcohol polyoxyethylene ether 3%.

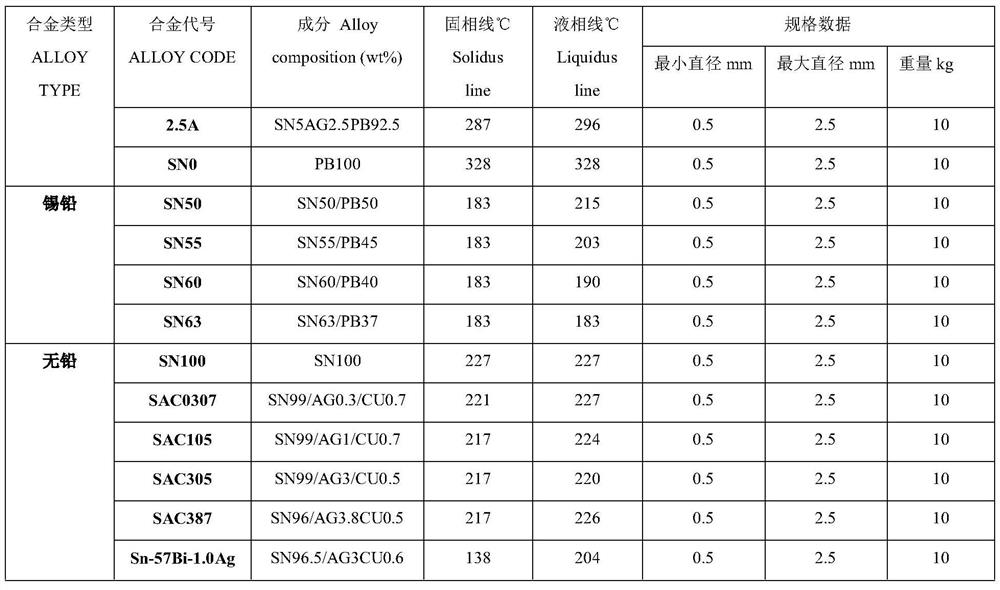

[0039] The tin-based metal alloy is a tin-copper alloy, and its specific composition and weight percentage are 99.3% tin, 0.7% copper, and a melting point of 227 degrees.

[0040] The method for preparing solder wire capable of low-temperature welding of stainless steel materials includes the following steps:

[00...

Embodiment 2

[0060] A solder wire capable of low-temperature welding of stainless steel materials includes an external tin-based metal alloy and an internal solid activator. The weight percentage of the tin-based metal alloy is 97.8% and the weight percentage of the solid activator is 2.2%.

[0061] The solid active agent, calculated by weight percentage, has a raw material composition of 31% highly hydrogenated rosin, 10% fluoride salt, 10% polyethanolamine, 5% organic metal salt, 10% fluoroborate, and fluoride ion surface activity. Agent 5%, ethylene glycol 100-200 20%, castor oil thixotropic agent 5%, cetyltrimethylammonium bromide 3%, oleyl alcohol polyoxyethylene ether 1%.

[0062] The tin-based metal alloy is a tin-copper alloy, and its specific composition and weight percentage are 99.3% tin, 0.7% copper, and a melting point of 227 degrees.

[0063] The method for preparing solder wire capable of low-temperature welding of stainless steel materials includes the following steps:

[0064] (1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com