Automobile seat cover convenient to release airbag and machining method thereof

A seat cover and airbag technology, which is applied to seat covers, vehicle seats, vehicle parts, etc., can solve the problems of occupant injury, etc., and achieve the effects of increasing safety factor, good comfort, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

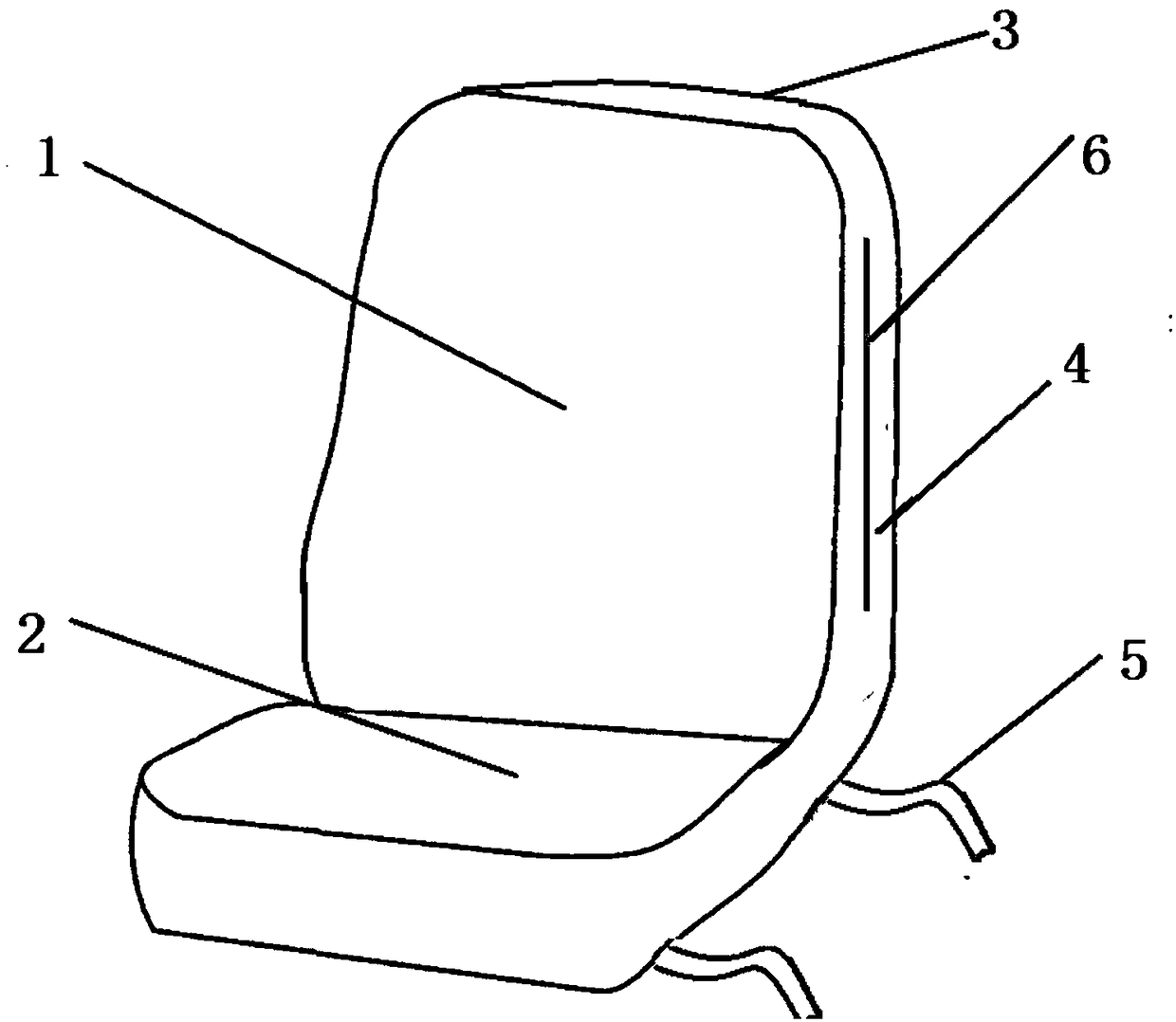

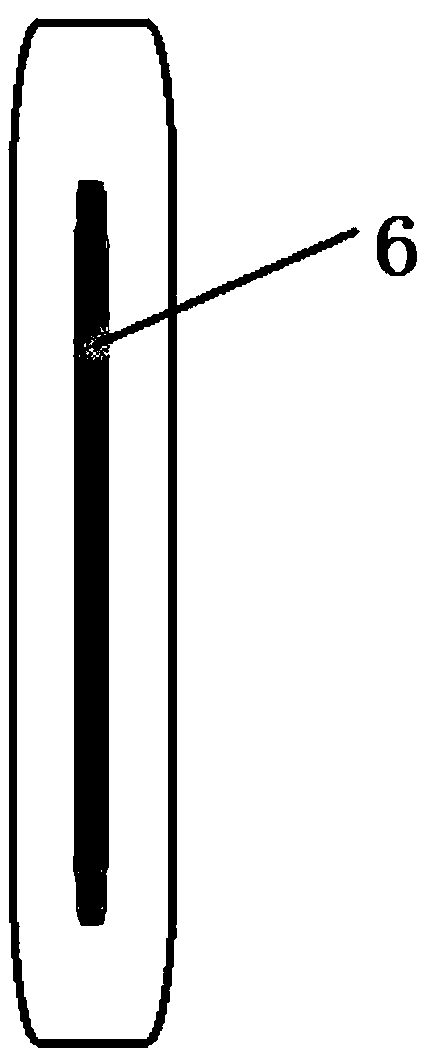

[0032] Example 1 as Figure 1~3 As shown, the car seat cover that is convenient for releasing the airbag is provided in the present embodiment, and the blasting opening of the airbag is arranged on the side of the seat cover of the car, and the length of the blasting opening of the airbag is greater than the maximum blasting diameter of the airbag. Since the blasting hole of the airbag is set on the side of the car seat cover, that is, at the position corresponding to the airbag, laser treatment is used in this embodiment to change the structural strength of the fabric of the blasting hole of the airbag, without affecting its appearance and use. It is easy to blast out in the event of a collision, and can play a protective role in time.

[0033] Specifically, this embodiment provides a car seat cover that is convenient for releasing an airbag, including a seat cover back cloth 1, a seat cushion cloth 2, a seat cover back cloth 3, a seat cover side cloth 4 and a ribbon 5; The ...

Embodiment 2

[0055] The only difference from Example 1 is that the seat cover backrest cloth 1 in this example is made of pure cotton and suede, and the area ratio of the pure cotton and suede is 1:1; The fabric of the cushion cloth 2 is composed of ice silk and satin net, and the area ratio of the ice silk and the satin net is 1:3; the fabric of the back cloth 3 is composed of South Korean cashmere and PU. The area of the South Korean velvet and PU is 1:2; the cloth of the seat cover side cloth 4 is composed of ice silk and sandwich, and the area of the ice silk and sandwich is 1:1. The car seat cover made of the above-mentioned cloth also has good anti-skid property, strong and wear-resistant, good air permeability, good hand feeling, high strength and good softness; meanwhile, the cloth of the side cloth 4 adopts a material with a ratio of 1 according to the size of the area. : 1 ice silk and sandwiches, under this ratio, adopt the laser technology to process the fabric of the airba...

Embodiment 3

[0057] The only difference from Example 1 is that the seat cover backrest cloth 1 in this example is made of pure cotton and suede, and the area ratio of the pure cotton and suede is 1:4; The cloth of the cushion cloth 2 is composed of ice silk and satin net, and the area ratio of the ice silk and the satin net is 1:5; the cloth of the back cloth 3 is composed of South Korean velvet and PU, so The area of the South Korean cashmere and PU is 1:6; the cloth of the seat cover side cloth 4 is composed of ice silk and sandwiches, and the area of the ice silk and sandwiches is 3:1. The car seat cover made of the above-mentioned cloth can also achieve good anti-skid property, strong and wear-resistant, good air permeability, good hand feeling, high strength and good softness; meanwhile, the cloth of the side cloth 4 adopts the cloth according to the area size ratio of 3:1 ice silk and sandwiches, at this time, the fabric of the airbag blast hole, that is, the side fabric 4, is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com