Anti-theft guardrail on construction site

A technology for construction sites and guardrails, applied in the field of anti-theft guardrails on construction sites, can solve problems such as high cost, accidental injury, and personal injury, and achieve the effect of good warning and reminder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

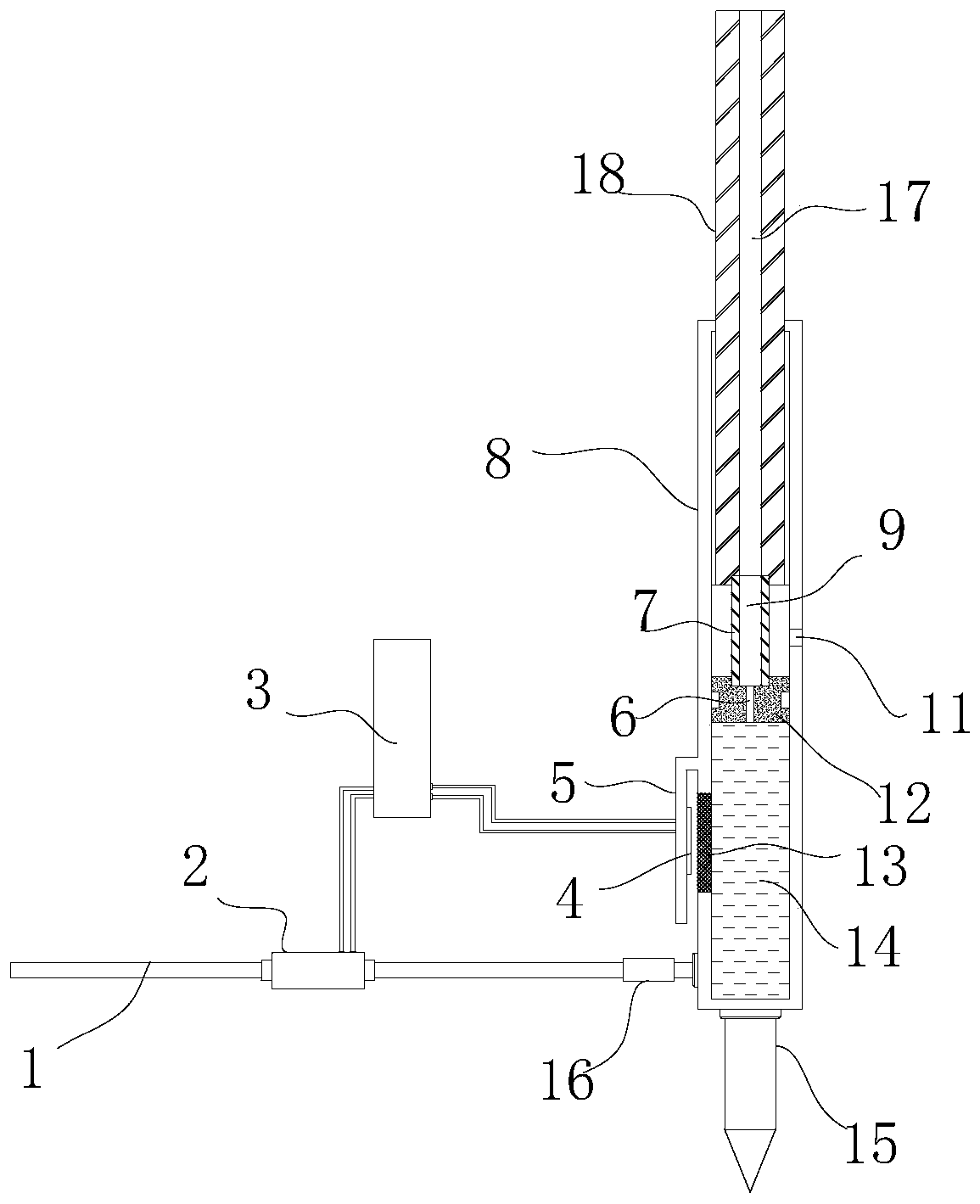

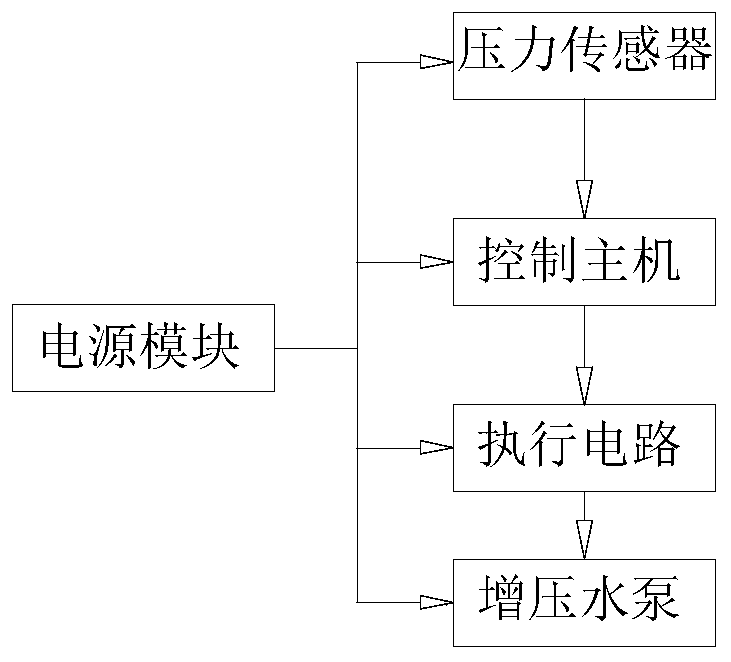

[0015] Such as figure 1 As shown, the construction site anti-theft guardrail includes guardrails arranged on the periphery of the construction site. The guardrail is composed of more than one railing. Each railing includes a fixed sleeve rod 8 and a telescopic rod inserted on the top of the fixed sleeve rod 8. 18. There is a water storage chamber 14 in the middle of the fixed sleeve rod 8, the inner end of the water storage chamber 14 is connected to a water delivery pipe 1, the input end of the water delivery pipe 1 is connected to an external water source, and a booster pump 2 is connected to the water delivery pipe 1 , a one-way valve 16 is installed on the water pipe at the output end of the booster pump 2, and a floating body 12 is sealed at the bottom of the telescopic rod 18. There is a drainage channel 17 in the middle of the telescopic rod 18, and the floating body 12 is connected to the drainage channel 17 through a connecting pipe 7. Conduction, the bottom of the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com