Non-coal-pillar mining method for roof caving roadway forming along goaf by crushing immediate roof

A coal pillar-free, direct technology, applied in ground mining, mining equipment, mining equipment, etc., can solve problems such as difficult roadway formation, and achieve the effect of easy promotion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Take a certain coal mine as an example to further illustrate the technical scheme of the present invention.

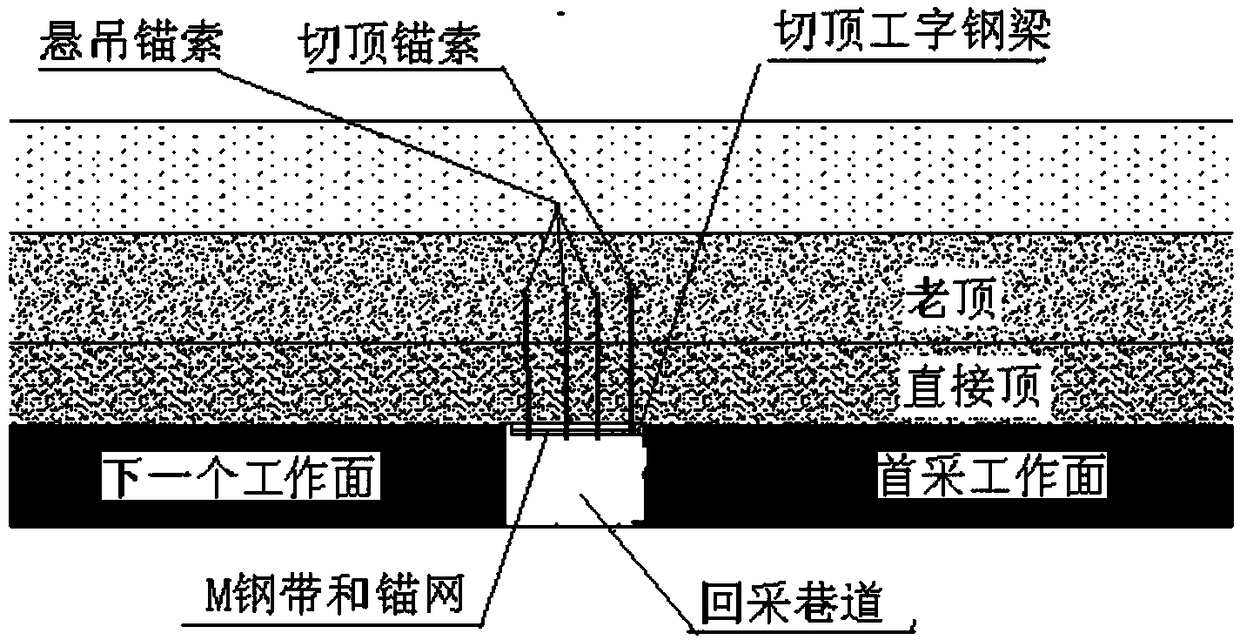

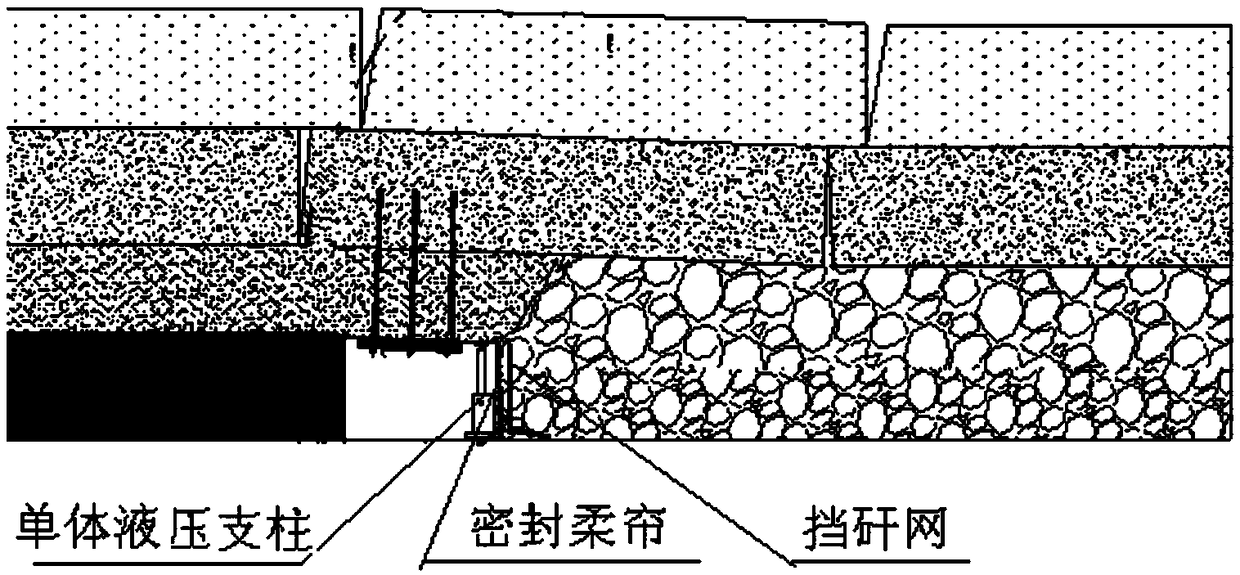

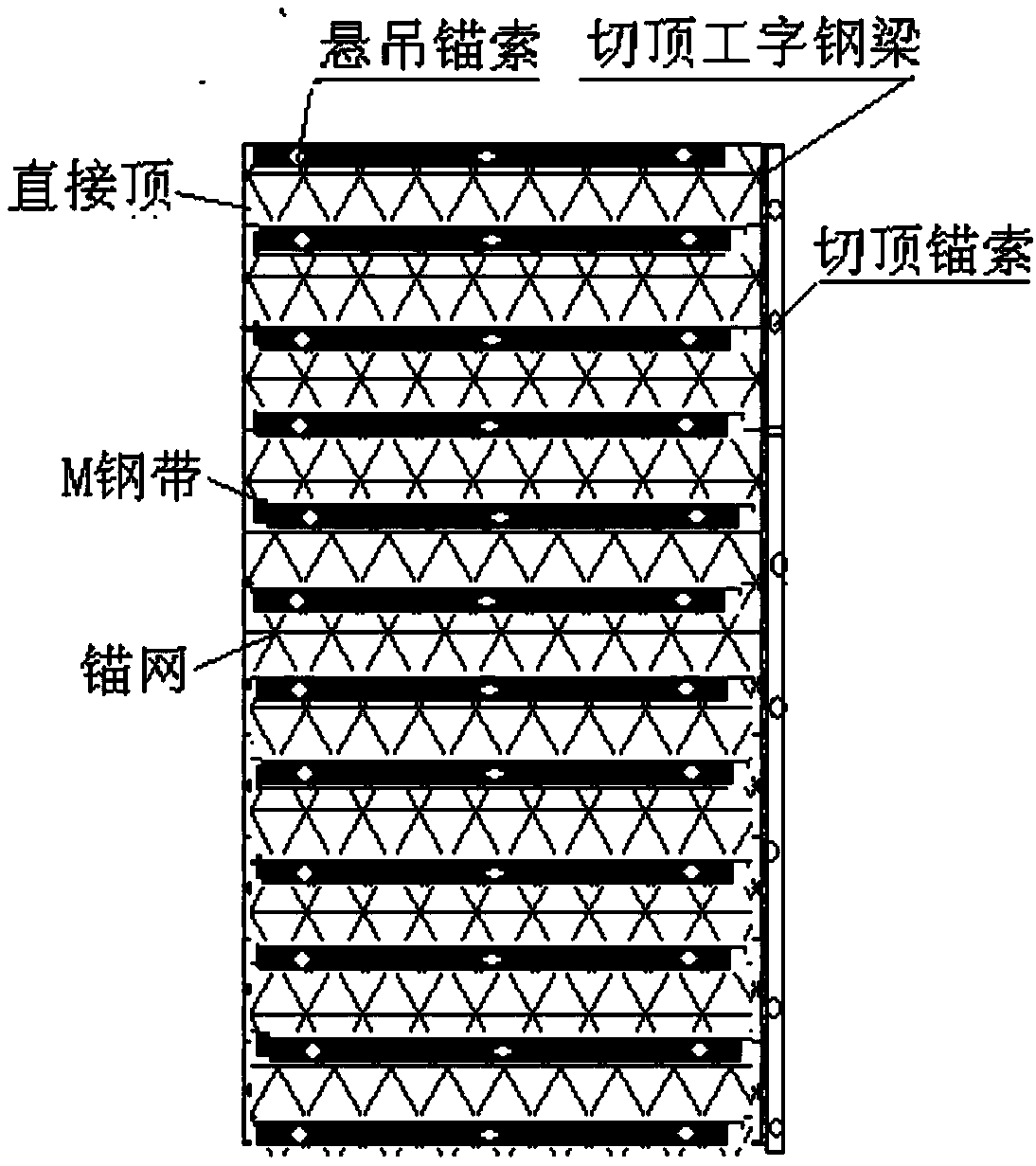

[0023] The coal seam mined in a certain coal mine is the second mining area of the third seam, the thickness of the third seam is 1.1m, most areas of the coal seam develop mudstone false roof, the thickness is about 0.3m, the direct roof is 3.5m of silty mudstone, and the direct roof density ρ =2.5t / m 3 ; Fissures are developed in the immediate roof. According to the mining situation in the first mining area, it is found that the immediate roof pops up with mining, which belongs to the situation of broken direct roof. The old top is gray-white fine sandstone and medium-fine sandstone, with a thickness of 1.5-9.0m and an average of 4.5m. The above-mentioned coal seam has adopted the mining method without coal pillars of the present invention by caving the roof along the gob and forming roadway:

[0024] Step one, such as figure 1 As shown, firstly, excavate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com