Novel ball pin damping sleeve type damper

A technology of shock absorber and shock absorber, which is applied in the direction of friction shock absorber, etc. It can solve the problems of shock absorber weakness, falling out, cracking, etc., and achieve the effect of increasing the pressing force, flexible and convenient disassembly and assembly, and improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

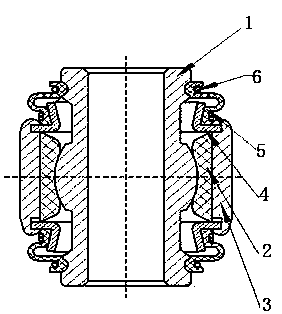

[0016] A novel ball-pin shock-absorbing sleeve type shock absorber, the shock absorber includes a shock-absorbing sleeve, and the shock-absorbing sleeve includes a spacer sleeve 1;

[0017] The middle part of the spacer sleeve 1 is provided with a friction body 2 clamped on the outer side of the spacer sleeve 1, and the outer side of the friction body 2 is provided with a compression sleeve 3 for limiting the friction body 2. Both sides of the body 2 are provided with baffles 4 on the outside of the spacer sleeve 1, the baffles 4 are clamped in the press sleeve 3, and the baffles 4 are provided with a position limiting function for the baffles 4. The dustproof ring 5 is clamped on the outer side of the spacer sleeve 1 through the clamp 6 .

[0018] The middle part of the spacer sleeve 1 protrudes, the protrusion of the spacer sleeve 1 is set in an arc, and the part of the friction body 2 and the spacer sleeve 1 is concavely set, so that the two form a concave-convex blocking f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com