Novel external heating type zinc melting furnace

An external heating and zinc melting technology, which is applied to furnaces, crucible furnaces, furnace components, etc., can solve the problems of unclear zinc blocks, increase energy waste, shaking, etc., and achieve the effect of speeding up zinc melting and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

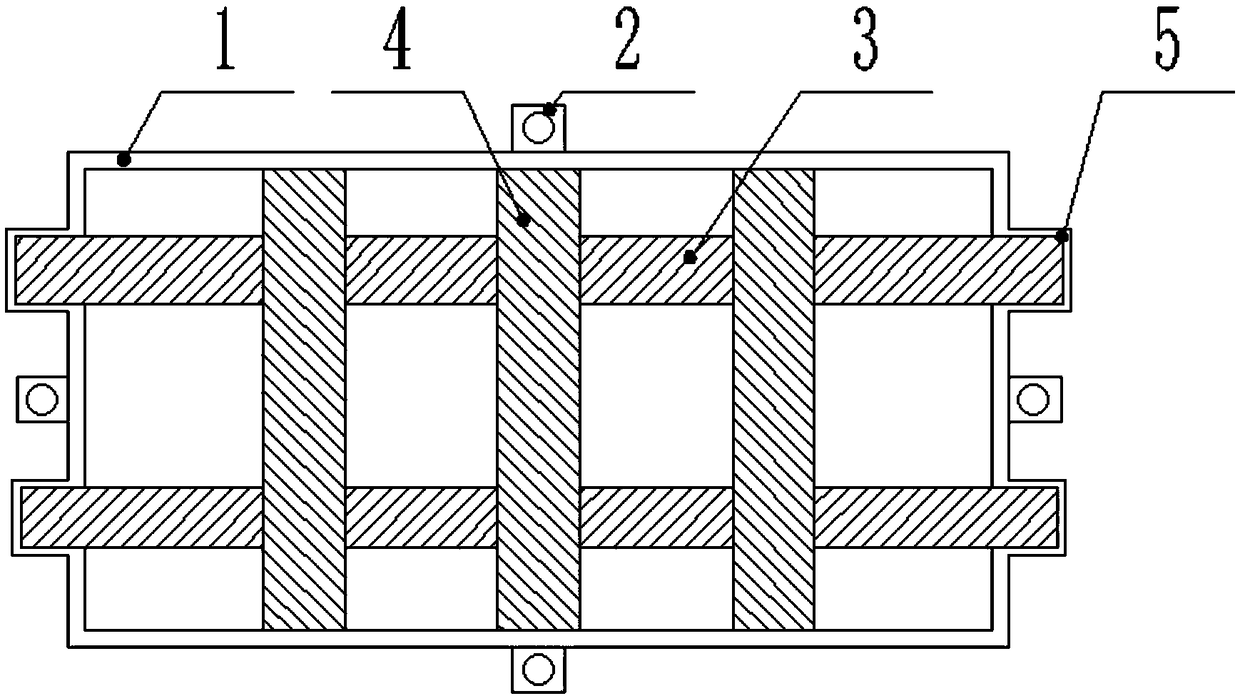

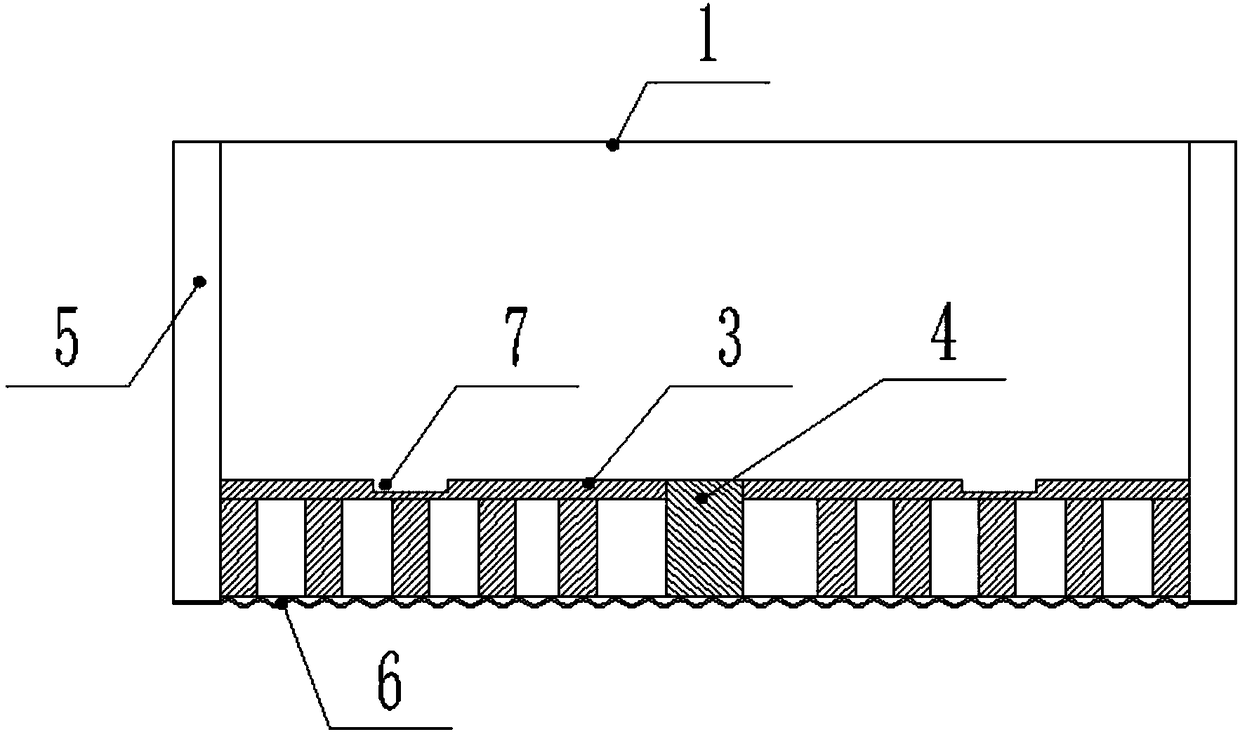

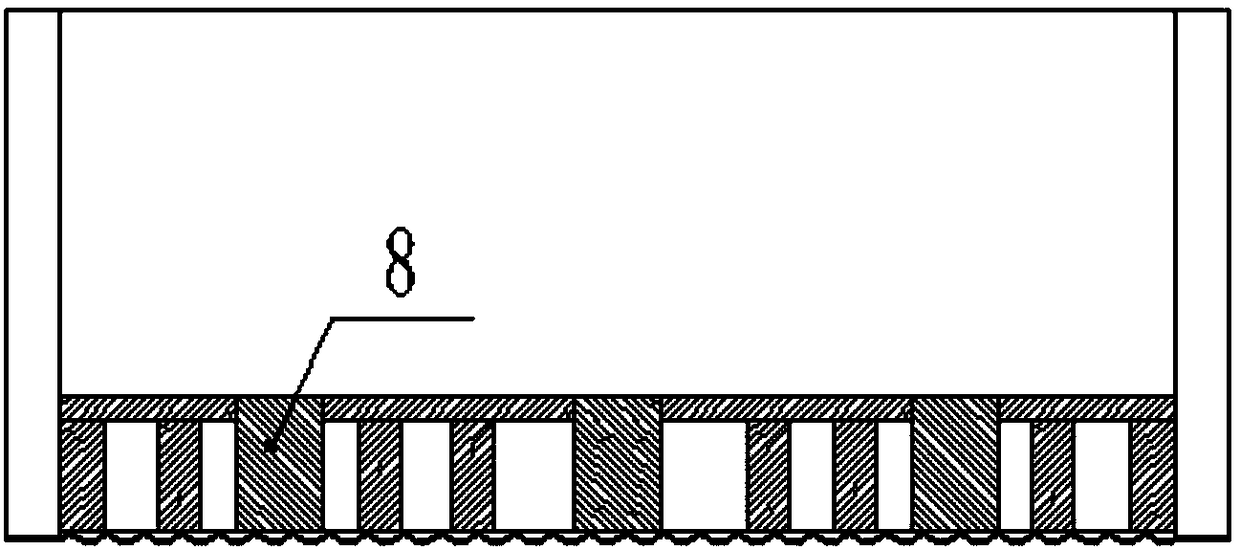

[0024] Such as Figure 1-4 As shown, a new type of external heating type zinc melting furnace includes a furnace body 1 and a furnace lug 2. The cross section of the furnace body 1 is rectangular, and the number of the furnace lugs 2 has two pairs, which are respectively welded on the furnace body 1 On the two opposite side walls, the furnace lugs 2 arranged oppositely are welded on the same straight line, which is convenient for the spreader to transfer the furnace body 1 . The furnace body 1 is provided with a baffle assembly, the baffle assembly includes a horizontal plate 3 and a first vertical plate 4, the horizontal plate 3 and the first vertical plate 4 are welded together and arranged in a staggered manner, and the horizontal plate The plate 3 and the first vertical plate 4 divide the furnace body 1 into several zinc melting units; the two sides of the horizontal plate 3 are provided with a slot 7, and the slot 7 is provided with a second vertical plate 8, the The sec...

Embodiment 2

[0029] Such as Figure 1-4 As shown, this implementation is further optimized on the basis of Embodiment 1. This embodiment focuses on the improvements compared with Embodiment 1, and the similarities will not be repeated. In this embodiment, the horizontal plate 3, the second Both the first vertical board 4 and the second vertical board 8 are in the shape of comb teeth. The comb-shaped design allows the phase-separated zinc blocks to flow through the gaps of the comb teeth after melting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com