Novel zinc melting furnace

A new type of zinc melting technology, applied in furnaces, crucible furnaces, furnace components, etc., can solve problems such as shaking, unclear zinc blocks, and increased energy waste, and achieve the effects of reducing weight, speeding up zinc melting, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

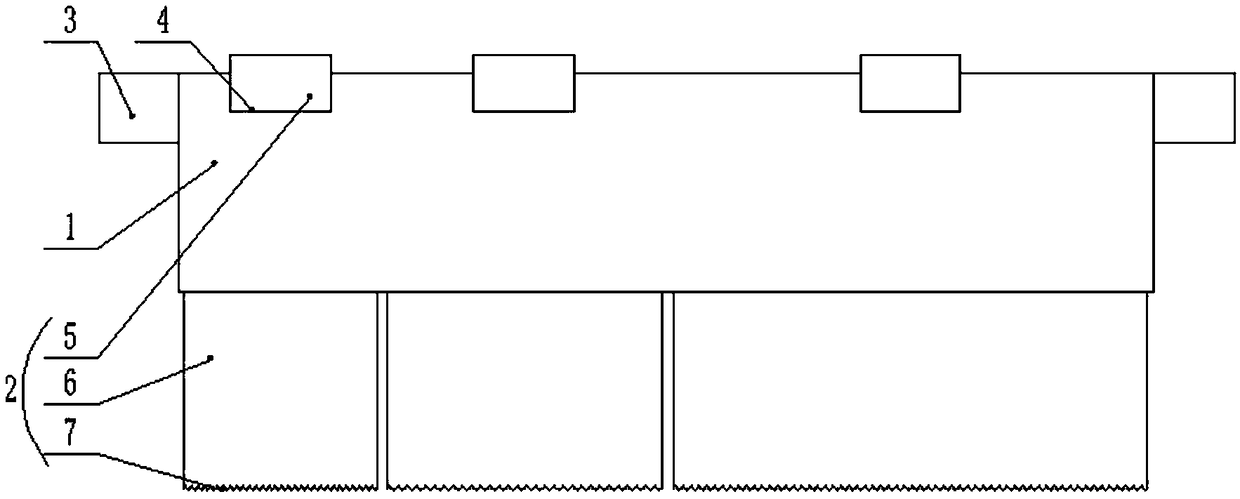

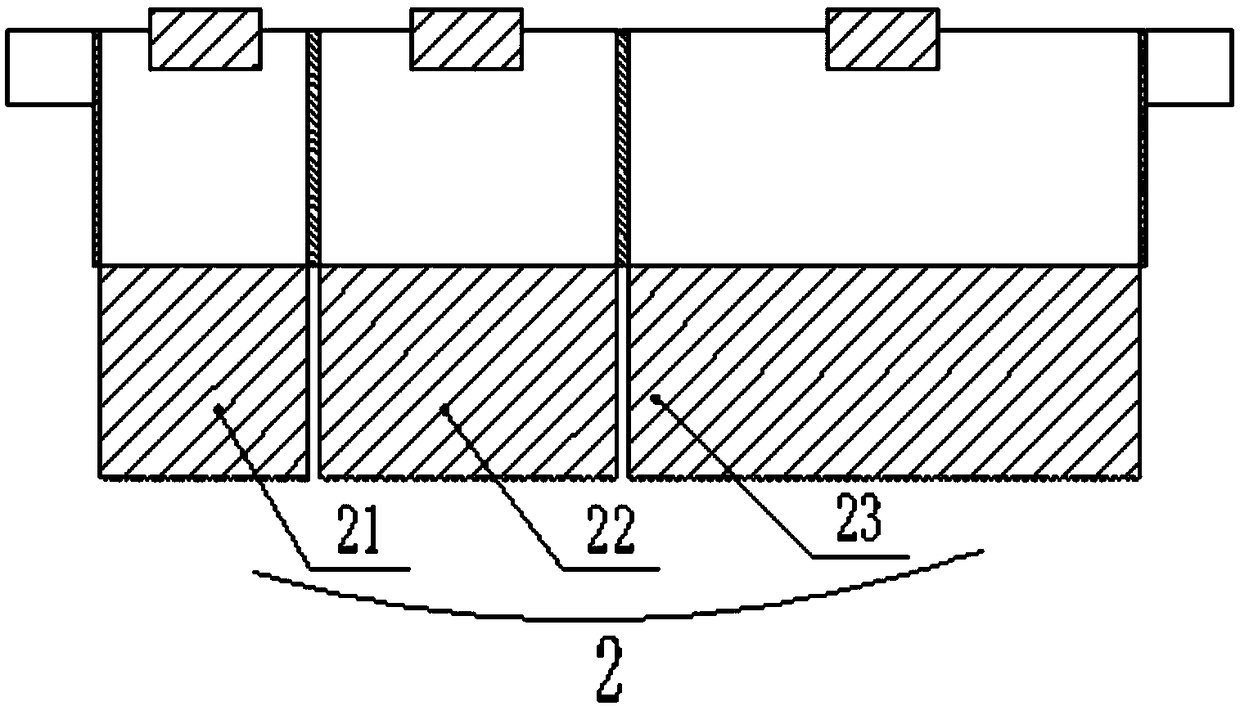

[0027] Such as Figure 1-4 As shown, a new type of zinc melting furnace includes an outer frame 1 and several inner furnaces 2. The outer frame 1 is a rectangular frame composed of four side walls, front, rear, left, and right. The left and right sides of the outer frame 1 Furnace lugs 3 are provided on the side walls of the outer furnace frame 1, and several groups of relative card slots 4 are provided on the side walls of the front and rear sides of the outer furnace frame 1;

[0028] The inner furnace 2 includes a furnace body 6, a bottom plate 7 and a block 5, the bottom plate 7 is arranged on the bottom of the furnace body 6, the block 5 is relatively arranged on the side walls of the front and rear sides of the furnace body 6, and the inner furnace hearth 2 and the outer hob 1 are clamped together through the clamping block 5 arranged in the clamping groove 4 . Both the outer frame 1 and the inner furnace 2 are made of steel plates.

[0029] The interior of the outer g...

Embodiment 2

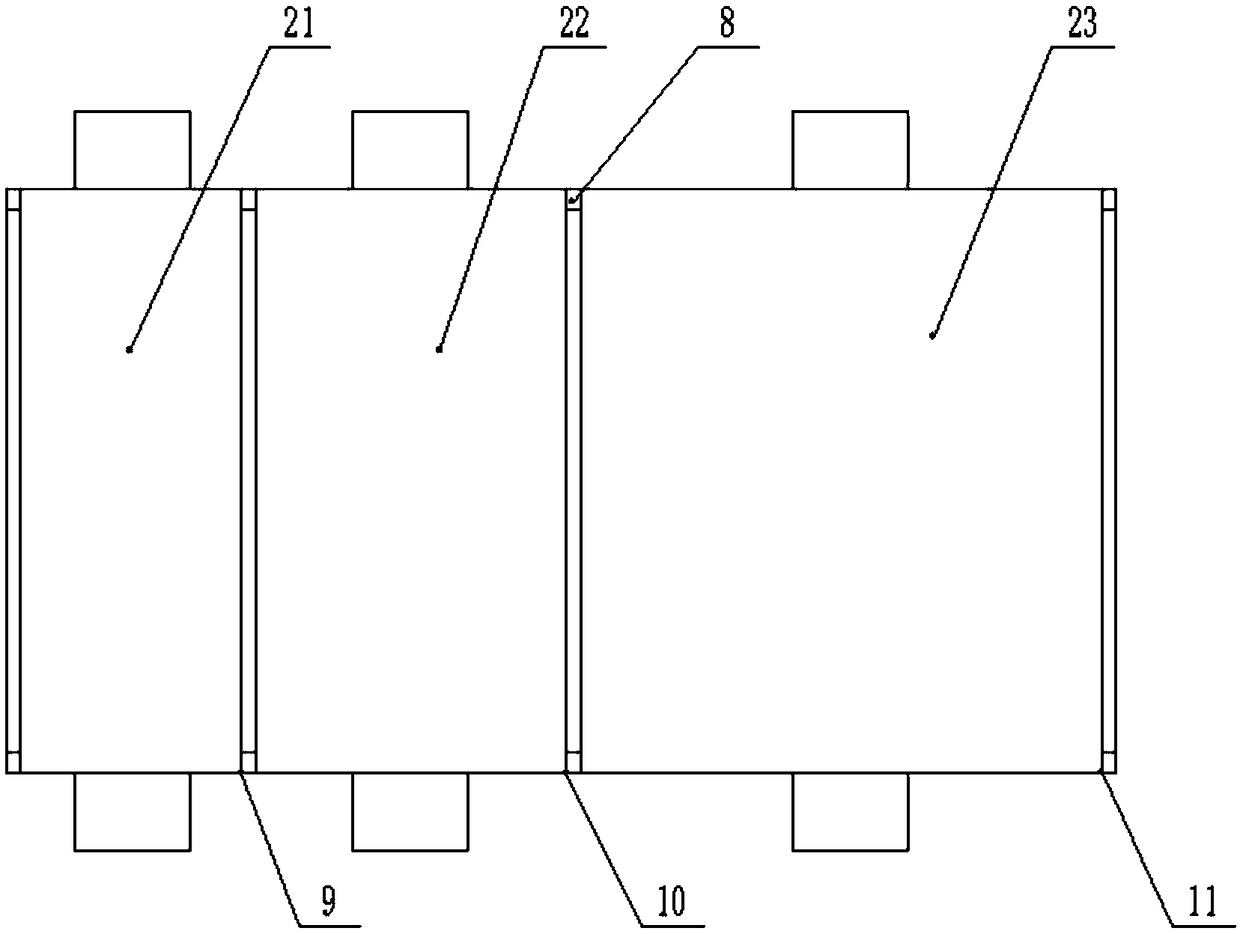

[0035] Such as Figure 1-4 As shown, this implementation is further optimized on the basis of Embodiment 1. This embodiment focuses on the improvements compared with Embodiment 1, and the similarities will not be repeated. In this embodiment, the inner furnace 2 Divided into the first inner furnace 21 , the second inner furnace 22 and the third inner furnace 23 , the volumes in the first inner furnace 21 , the second inner furnace 22 and the third inner furnace 23 increase sequentially. The inner furnace 2 with different volumes can make the amount and mode of molten zinc more flexible in the actual production process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com