Rolling-type insulation detection device

A detection device, a rolling technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of safety hazards in live work, inability to cover the entire length of the detected tool, and difficulty in accurately finding insulation failure parts, etc., to achieve Improve detection efficiency, improve reliability, and achieve zero damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

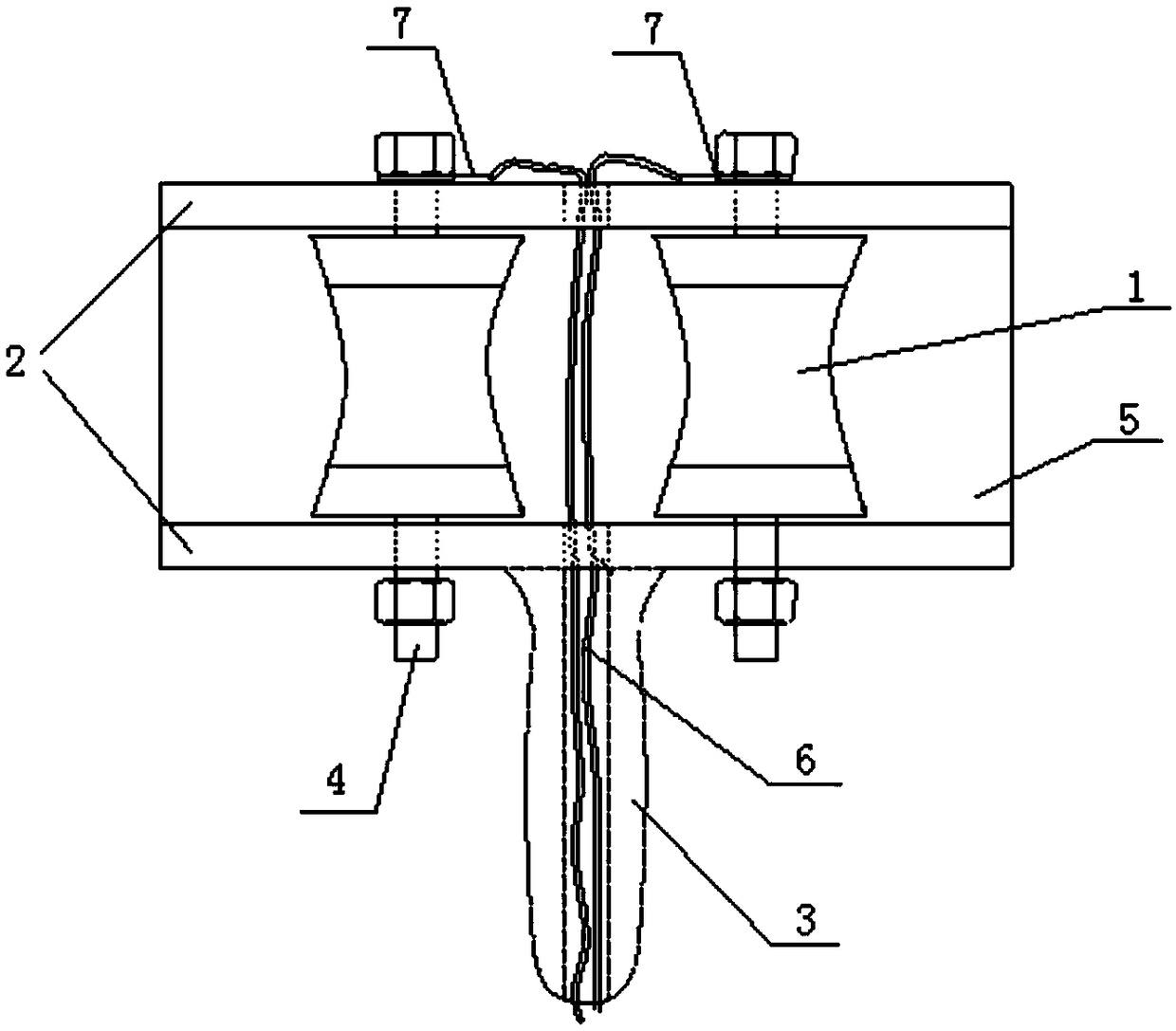

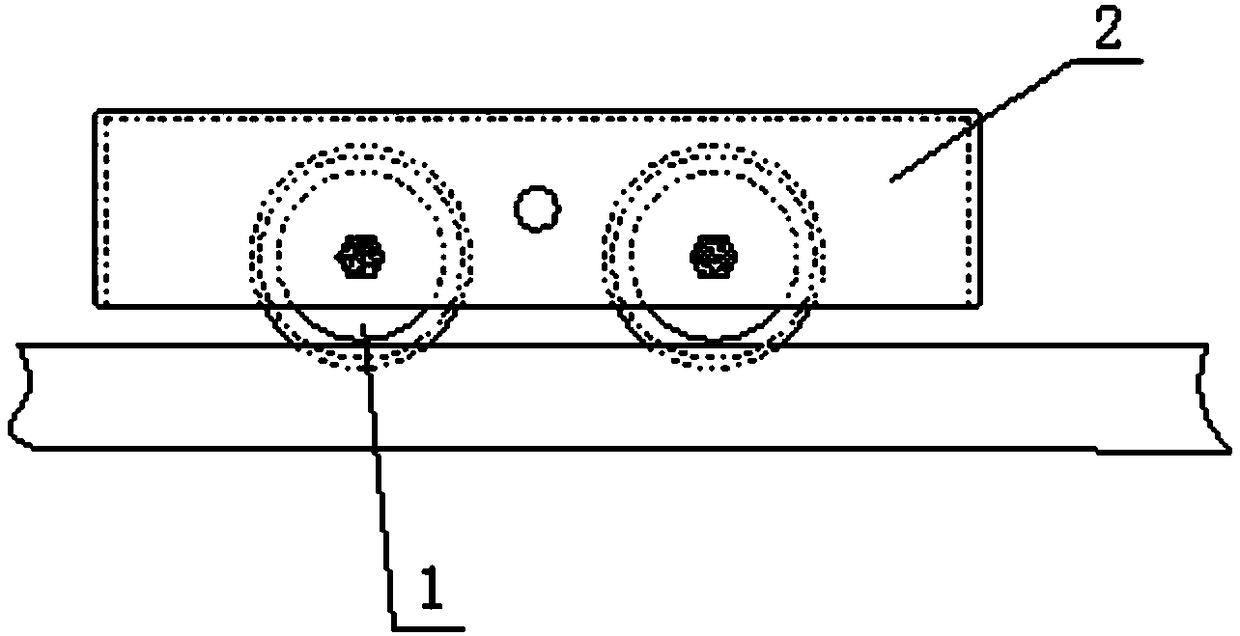

[0023] Such as figure 1 and figure 2 As shown, the rolling insulation detection device of the present invention includes a roller electrode 1, an insulating side plate 2, and an insulating handle 3. The roller electrode is made of metal material. Between the parallel insulating side plates, there is also a bearing on the rotating shaft; the roller electrode is hourglass-shaped, and the middle is sunken inward. This shape can make the roller electrode fit different diameter insulating rods or insulating ropes, and increase the number of roller electrodes and insulating rods. Or the contact area of the insulating rope; it can further cover the outer surface of the roller electrode with high-density conductive sponge, the conductive sponge has the characteristics of long conductive period and is not affected by temperature and humidity, which can further increase the conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com