Venturi with multi-concentration control and its control method

A multi-concentration, Venturi technology, applied in a variety of fluid ratio control, separation methods, ratio control, etc., can solve the problems of improving the concentration control of dust removal liquid, achieve the effect of optimizing dust removal effect, improving dust removal efficiency and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

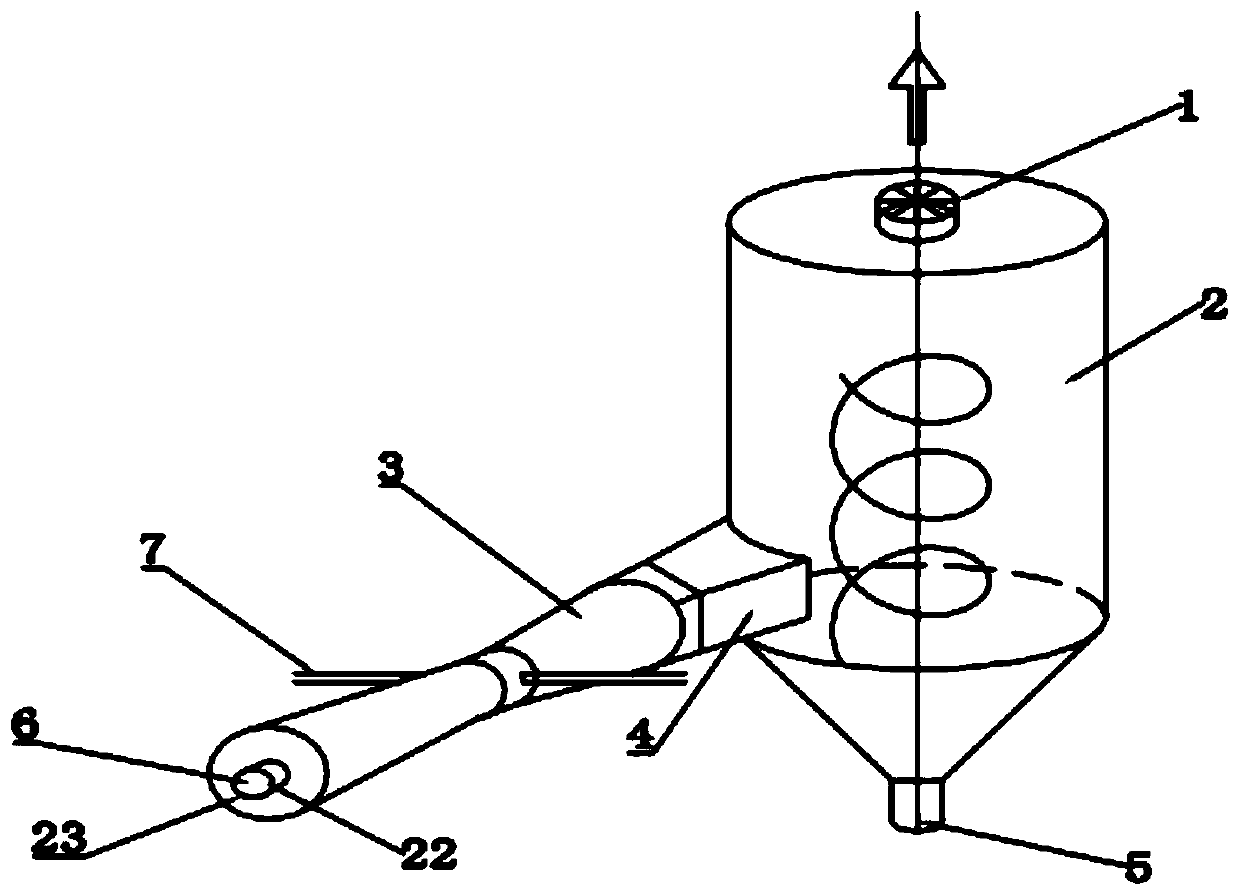

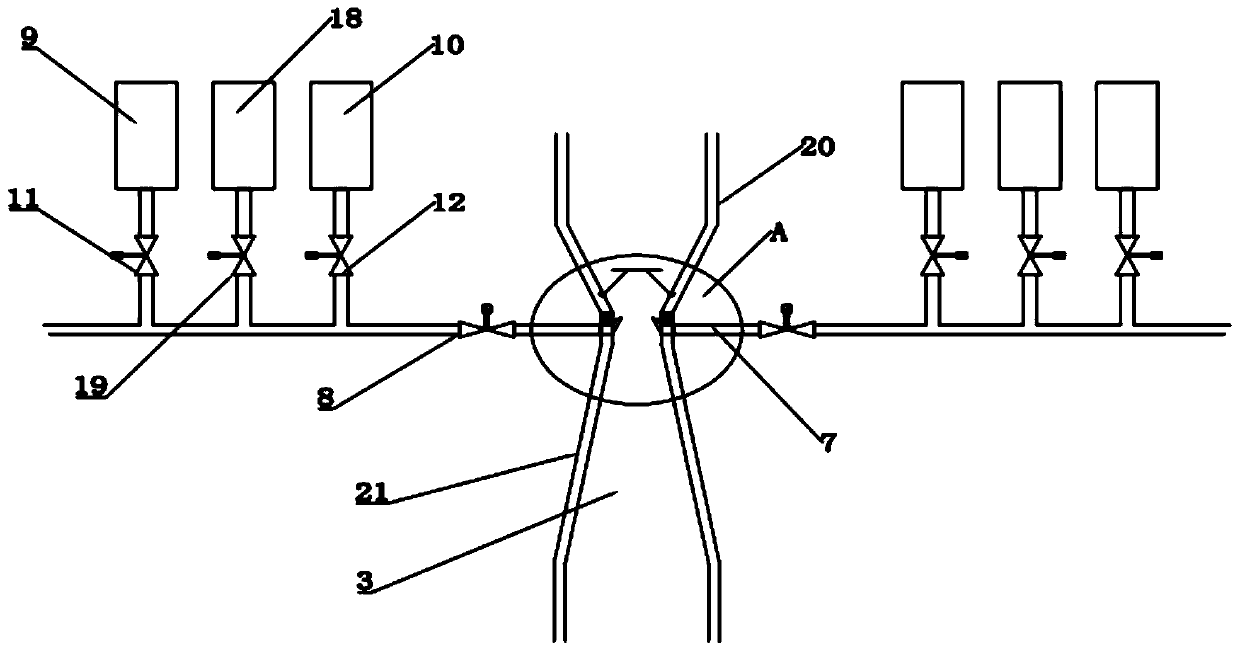

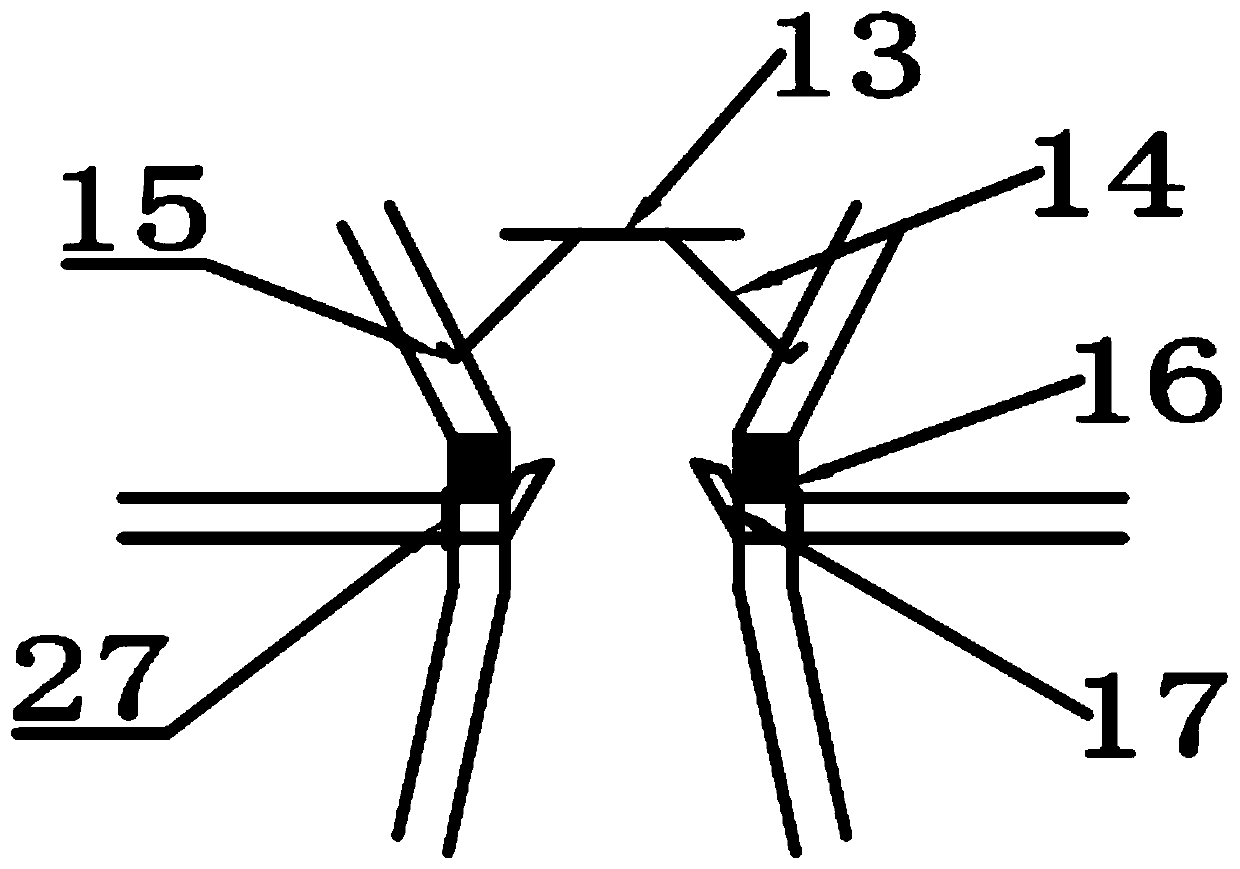

[0024] Such as figure 1 As shown, the Venturi is connected with the centrifugal separator (2) in use, and the dusty gas (6) passes through the Venturi tube (3), and then enters the centrifugal separator (2) through the airflow regulator (4), A racemator (1) is provided at the bottom of the centrifugal separator (2). A liquid inlet (7) is connected to both ends of the throat on the Venturi tube (3).

[0025] In order to measure the flow rate and composition of the gas in the dusty gas (6), a flow sensor (22) and an infrared gas sensor (23) are arranged at the inlet of the Venturi tube (3), and the flow sensor (22) and the infrared gas sensor (23) ) are respectively connected with the controller (24), and the controller (24) displays the gas flow rate and concentration through the indicating circuit (26). When the gas flow rate measured in the flow sensor (22) is faster, the indicator circuit (26) will The faster the flashing frequency of the indicator light, when the gas con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com