Wafer cleaning device and wafer cleaning method

A technology for cleaning devices and wafers, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc. It can solve problems such as wafer defects, achieve the effects of shortening the cycle, increasing the horizontal thrust, and relieving the pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

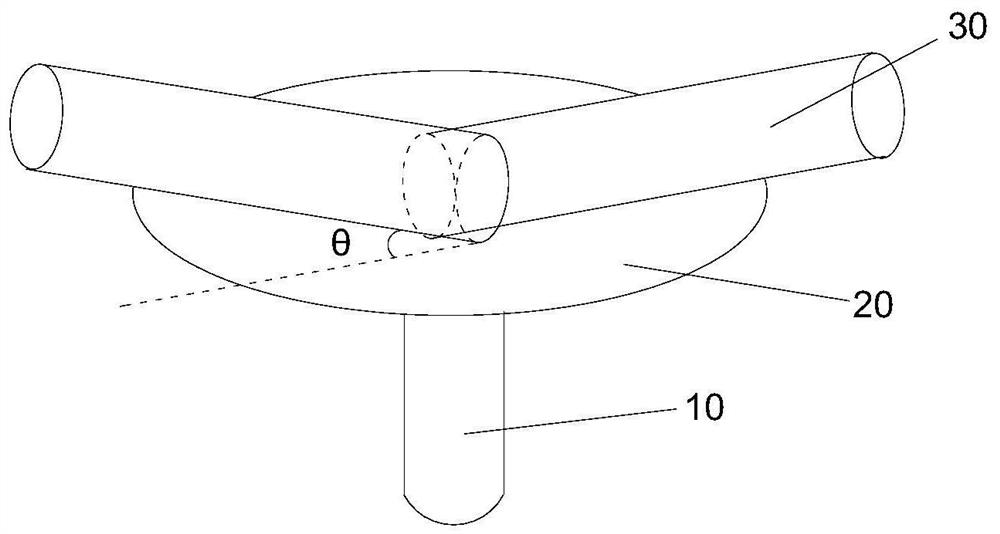

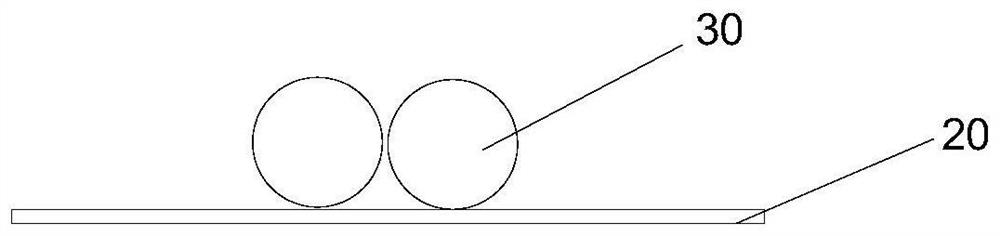

[0054] The wafer cleaning device provided in this embodiment is as Figure 5 As shown, base 10 has a first surface for carrying wafer 20, and the wafer cleaning device includes two deionized water nozzles 30, each deionized water nozzle 30 is arranged above the first surface of base 10, each deionized The angle between the spraying direction of the water nozzle 30 and the first surface is 0°<θ<90°, one deionized water nozzle 30 has a first water outlet, the other deionized water nozzle 30 has a second water outlet, and the second deionized water nozzle 30 has a second water outlet. The outer side of the first water outlet and the second water outlet are in contact with each other, the radial sections of the first water outlet and the second water outlet are rectangular with the same shape and area, and at least one of the first water outlet The side and at least one side of the second water outlet are parallel to each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com