Full-automatic loading and unloading integration equipment for fence stand columns or cross bars

A guardrail column, fully automatic technology, applied in the direction of the injection device, etc., to achieve the effects of superior stability, simple programming, and high safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

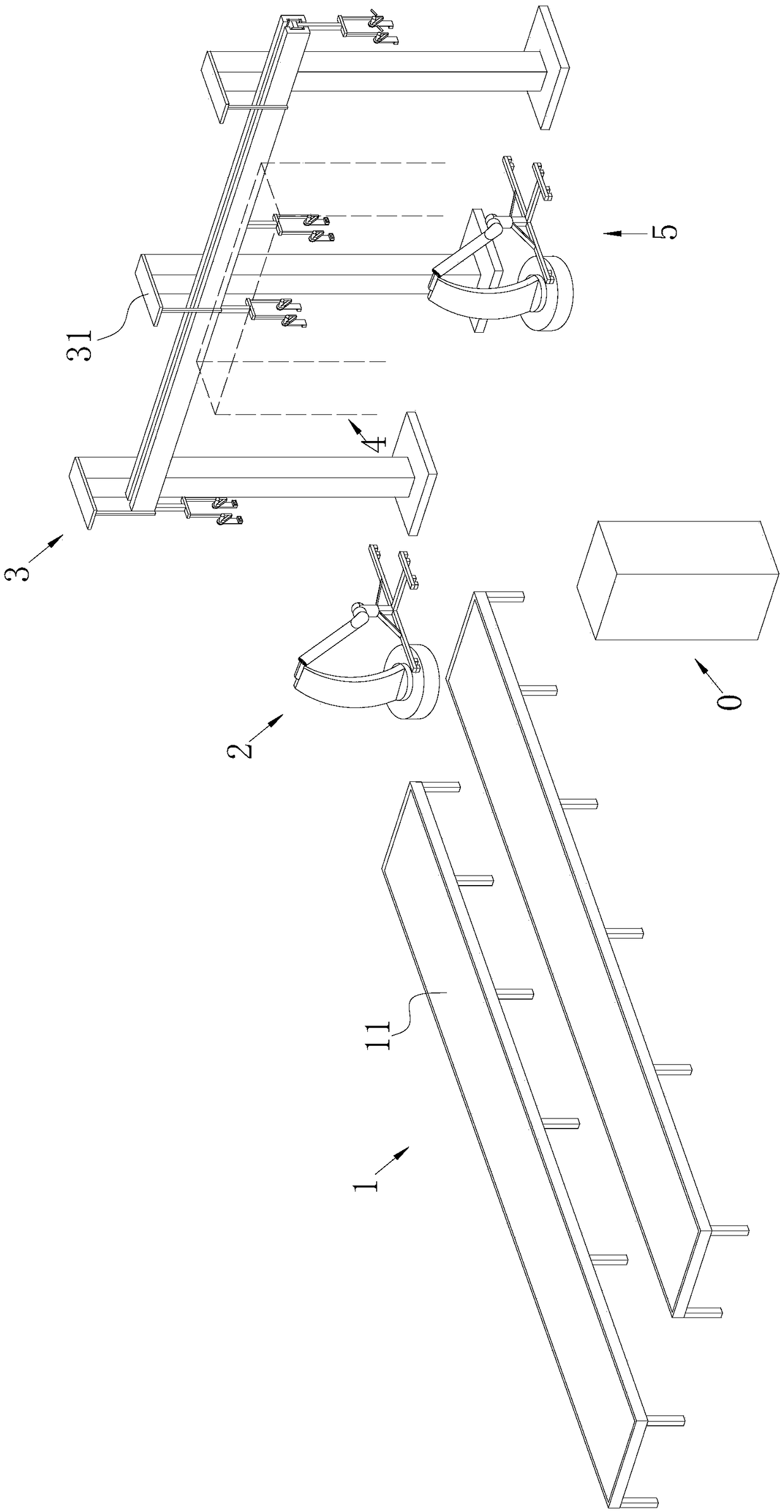

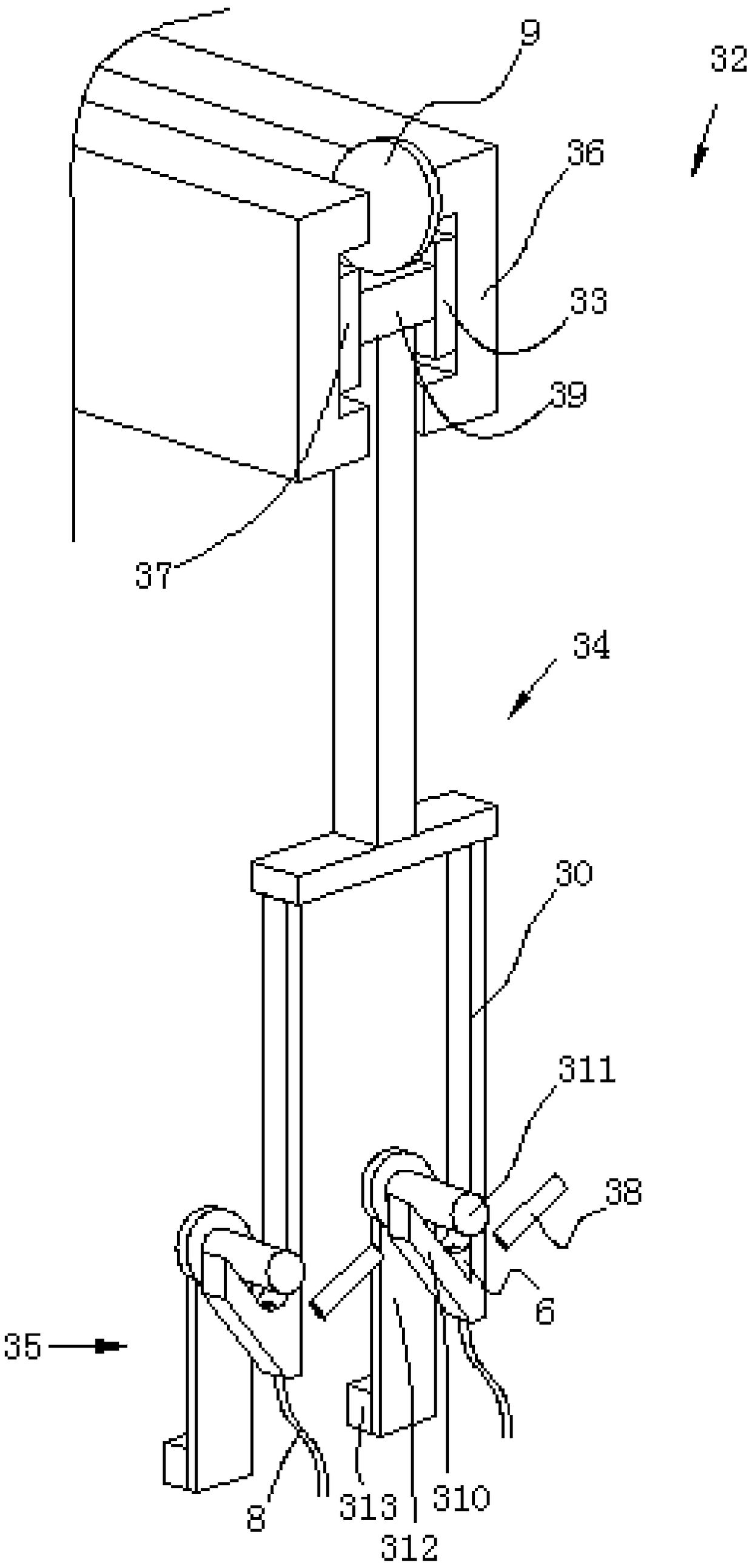

[0022] Such as figure 1 As shown, the automatic loading and unloading integrated equipment for guardrail columns or crossbars includes: electric control cabinet 0; first conveying part 1, loading mechanical arm 2, second conveying part 3, spraying part 4 and unloading mechanical arm 5.

[0023] The electric control cabinet 0 can coordinate and control the actions of each component; it is the prior art, not the key point of the present invention, and will not be repeated here.

[0024] The first conveying part 1 includes at least one conveying platform 11 , and in this embodiment, it has two parallel conveying platforms 11 .

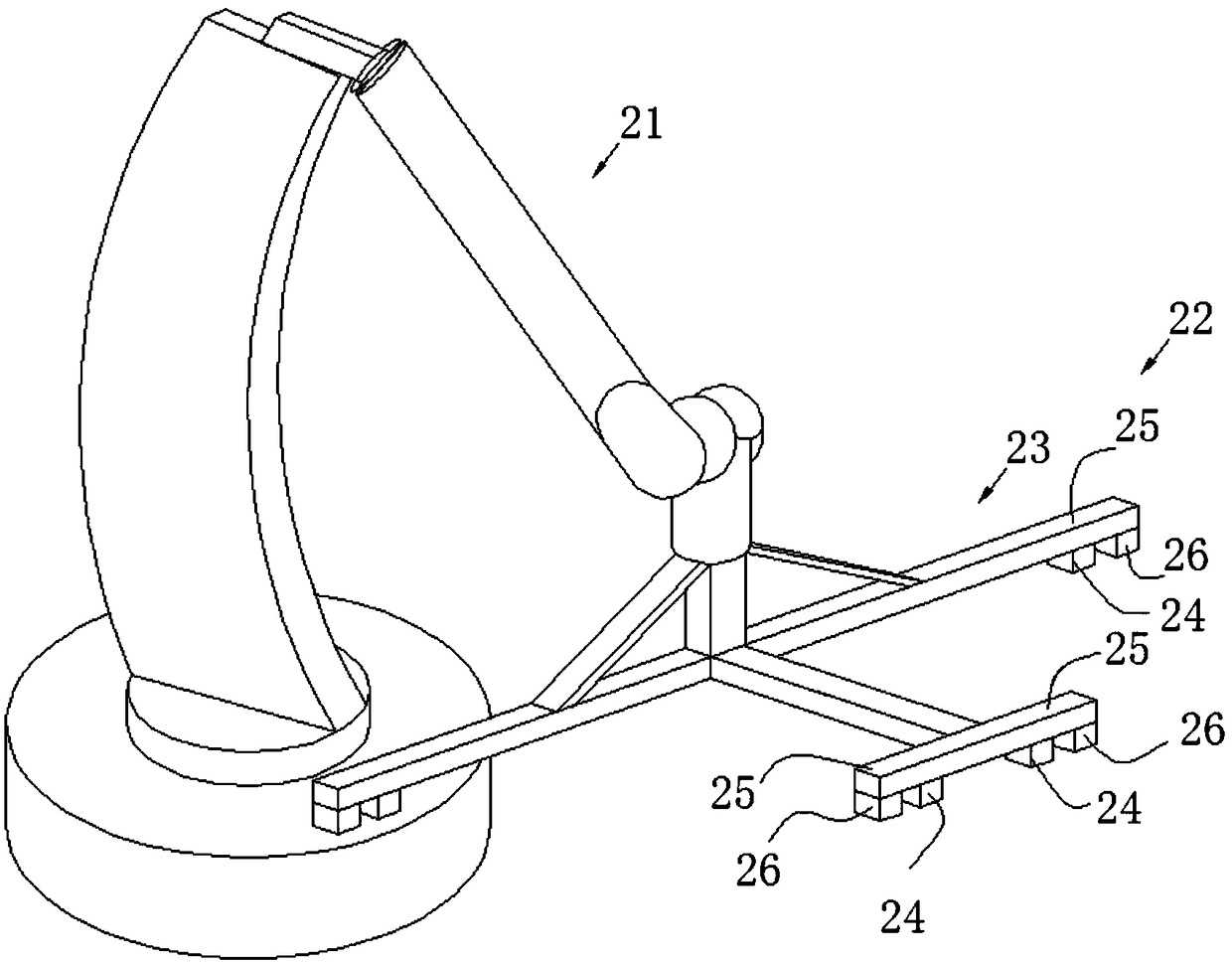

[0025] Such as figure 2 As shown, the loading robot arm 2 is located downstream of the first conveying part 1, and it includes a robot arm body 21 and a clamp 22 installed on the robot arm body 21 for clamping the guar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com