Parts processing device for pipeline antifreeze equipment

A technology for processing devices and parts, which is applied in the field of parts processing equipment for underground structures, can solve problems such as edges and corners, breakage, etc., and achieve the effect of avoiding overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below through specific implementations:

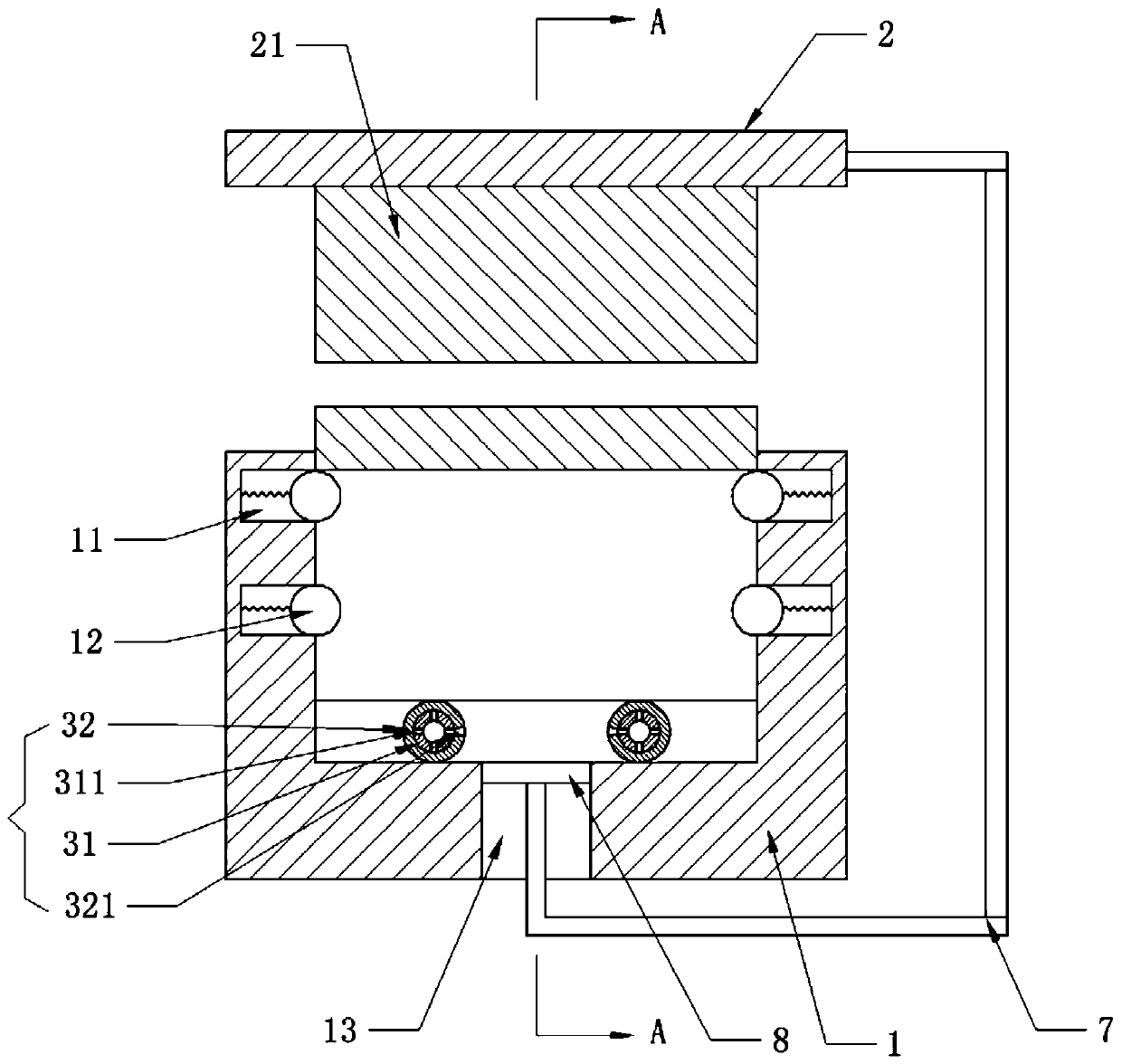

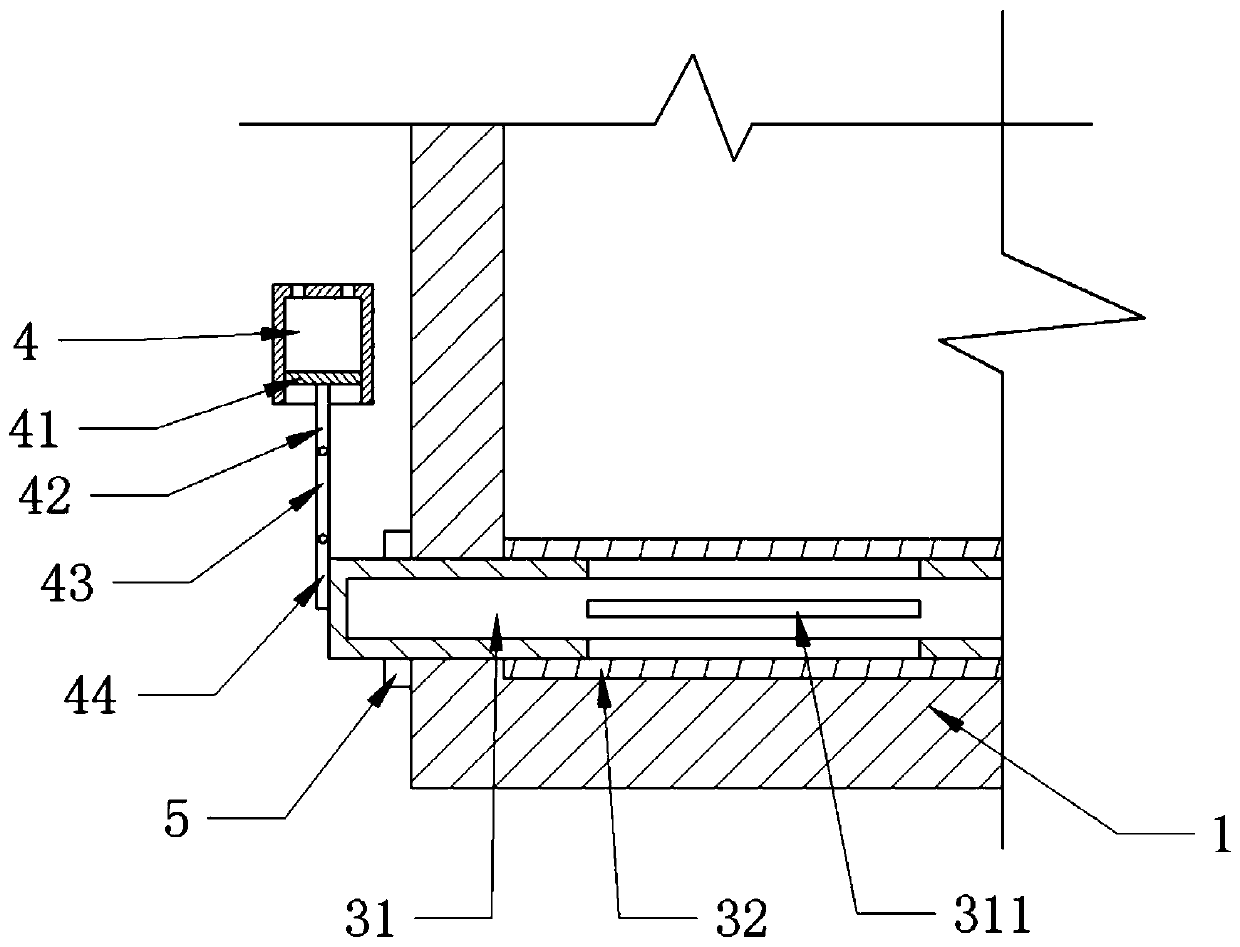

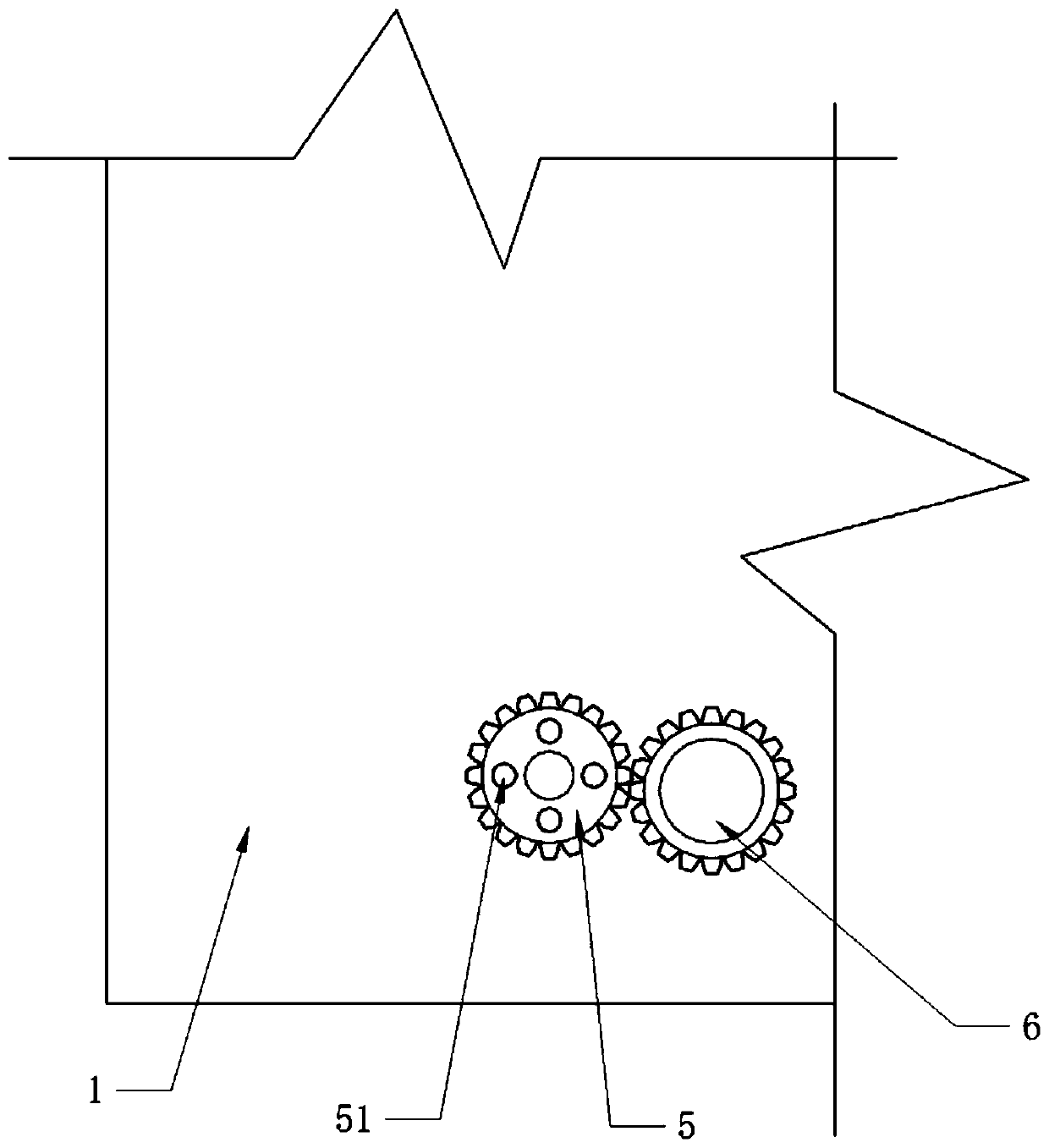

[0031] The reference signs in the drawings of the specification include: lower mold 1, mounting groove 11, sphere 12, demolding port 13, upper mold 2, pressing block 21, support roller 3, inner cylinder 31, through hole 311, outer cylinder 32, Air inlet 321, piston barrel 4, sliding plate 41, first support rod 42, second support rod 43, third support rod 44, first gear 5, air hole 51, second gear 6, concave rod 7, seal block 8 .

[0032] Such as figure 1 As shown, the component processing device of the pipeline antifreeze equipment includes a frame. The frame is provided with a lower mold 1 and an upper mold 2 located above the lower mold 1, and the upper mold 2 is slidably connected to the frame. The upper surface of the lower mold 1 is provided with a cavity, and the bottom of the upper mold 2 is provided with a pressing block 21. The left and right sides of the cavity are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com