A glass assembly with a bracket

A glass and assembly technology, applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve problems affecting the overall appearance, water leakage costs, etc., and achieve the effects of providing aesthetics, reducing the risk of water leakage, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be further described below in conjunction with the accompanying drawings.

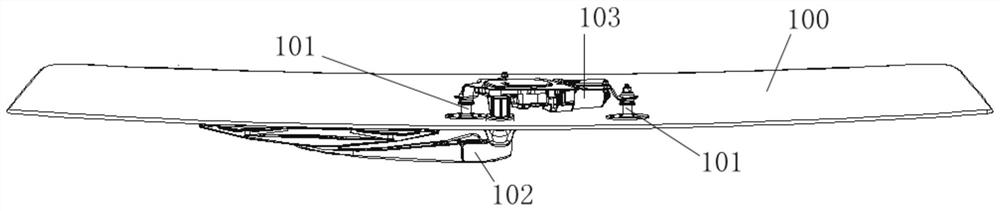

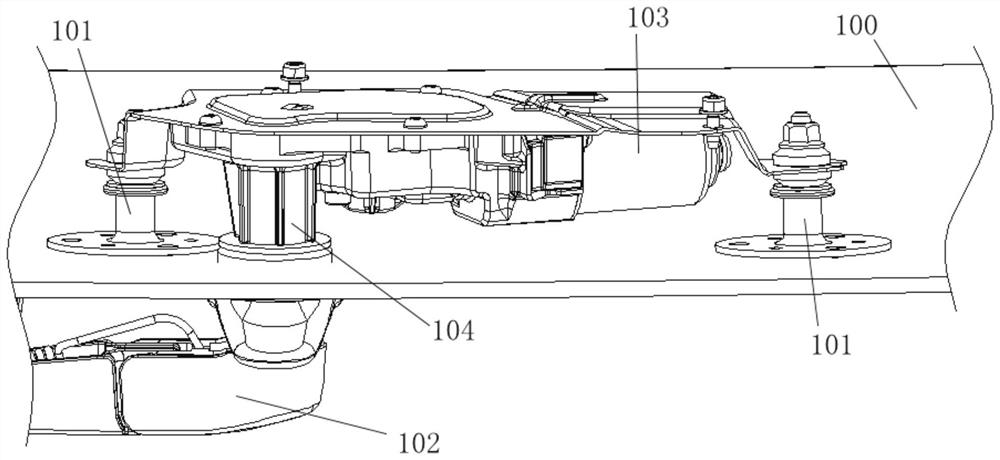

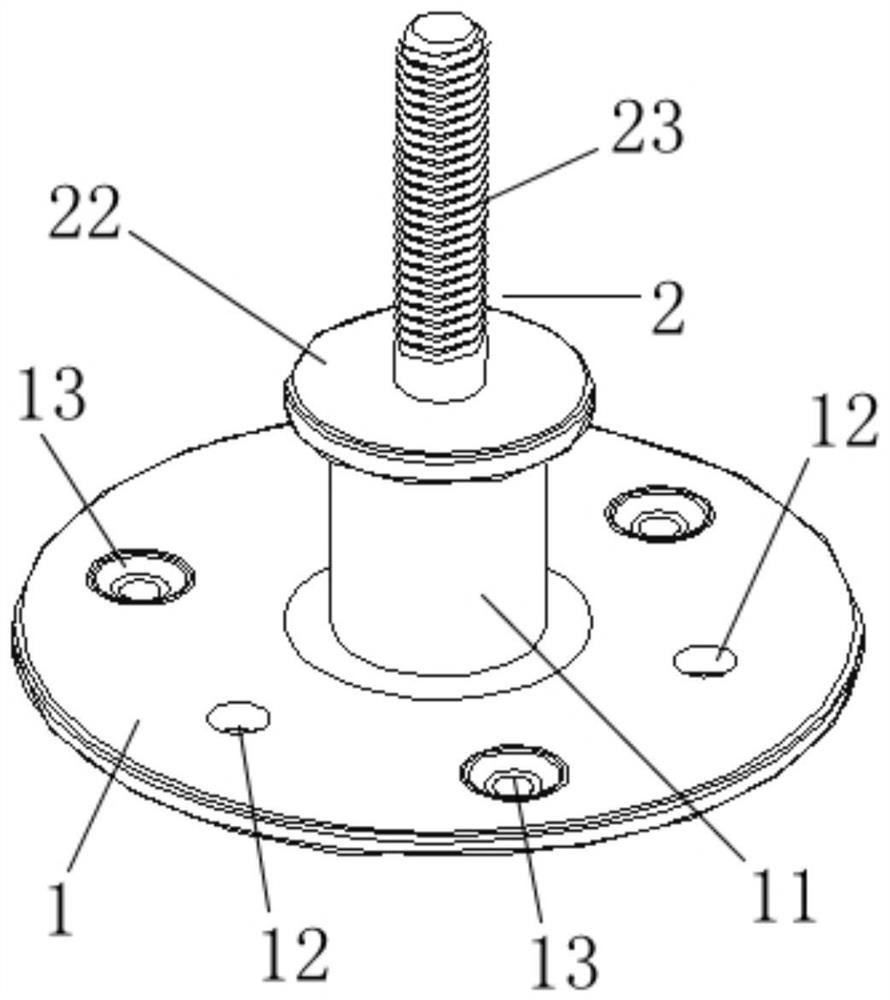

[0021] Such as figure 1 and figure 2 As shown, a glass assembly with a bracket according to the present invention includes a glass substrate 100 and at least one bracket 101 , and the bracket 101 is fixed on at least one surface of the glass substrate 100 .

[0022] exist figure 1 and figure 2 In the present invention, a wiper blade assembly 102 with a rain sensor is installed on the outer surface of the glass substrate 100, and two brackets 101 are fixed on the inner surface of the glass substrate 100, and the motor 103 of the rain sensor passes through Two brackets 101 are installed on the glass substrate 100, the wiper arm spindle 104 of the rain sensor can pass through the glass substrate 100 and are respectively connected with the wiper blade assembly 102 and the motor 103, and the motor 103 can drive the wiper arm spindle 104 rotates, thereby...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap