Sealing device of thermal forming packaging machine

A packaging machine and thermoforming technology, used in packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of poor sealing effect and the lack of fixing of the forming box, so as to improve the sealing yield and inhibit the growth of bacteria. , the effect of avoiding health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

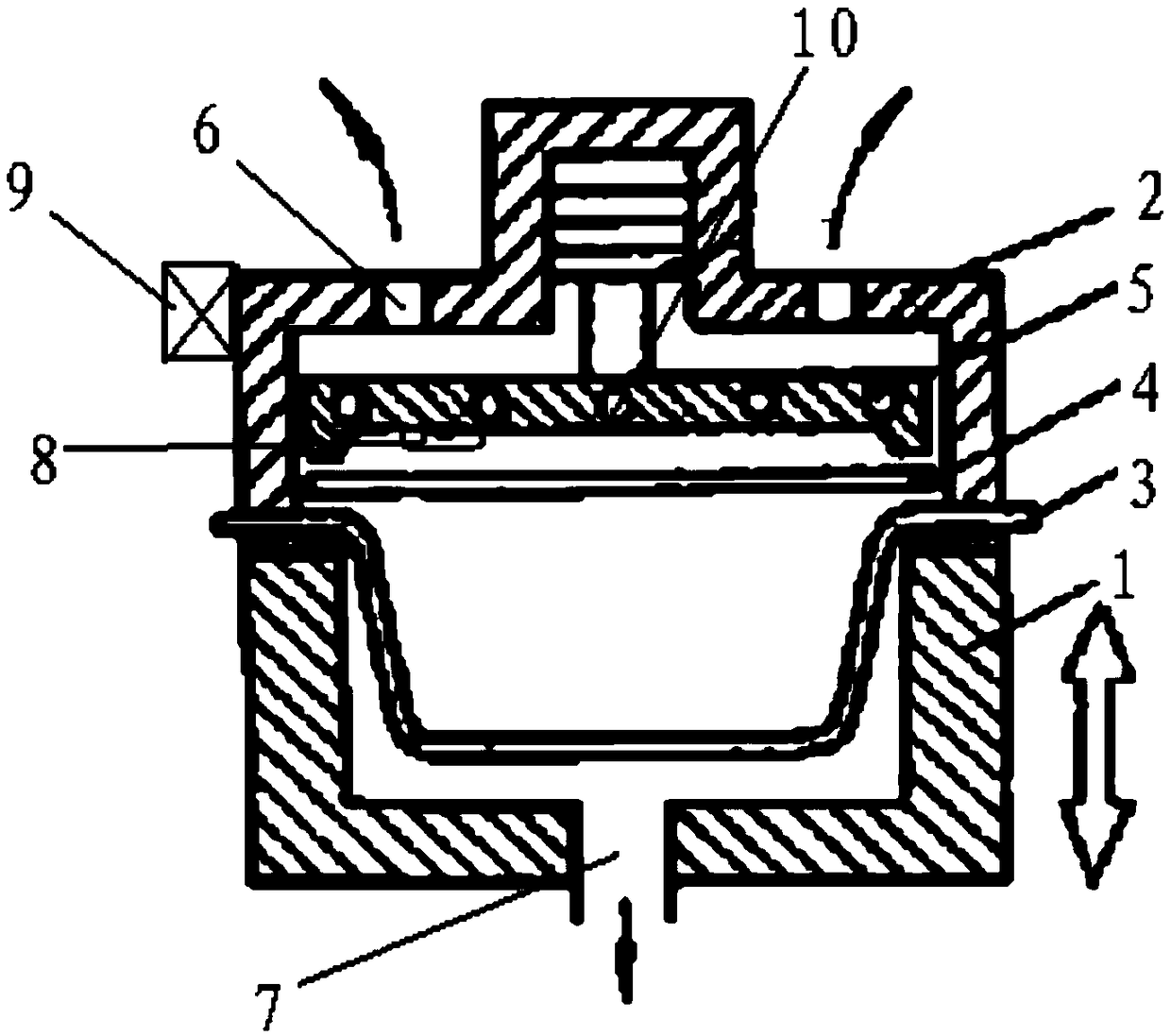

[0026] When in use, the forming box 3 is placed in the supporting mold 1, and the cylinder drives the supporting mold 1 to move up to make it combine with the upper chamber seat 2, and the forming box 3 is fixed on the supporting mold 1 and the upper chamber seat 2. In the formed sealing cavity, an antibacterial film is provided on the contact surface of the upper seat chamber 2, the supporting mold 1 and the forming box 3, and the antibacterial film can effectively inhibit the growth of bacteria, and avoid the health hazard caused by the growth of bacteria in the forming box;

[0027] The cylinder drives the heat-sealing plate 5 to move down, and the temperature of the heat-sealing plate 5 is controlled by a temperature control meter; the heat-sealing plate 5 seals the lower film 4 located below it on the forming box 3, and the forming box 3 is higher than the upper film. 4 15mm wide, to complete the seal.

[0028] Heat-sealing plate 5 is provided with temperature sensor 8, a...

Embodiment 2

[0030] When vacuuming is required, the upper air valve 6 and the lower air valve 7 are opened, so that the sealing cavity formed by the supporting mold 1 and the upper chamber seat 2 is pumped up and down simultaneously to avoid pressure difference and ensure the vacuuming effect. After vacuuming, the upper gas valve 6 and the lower gas valve 7 can switch the gas valves to charge inert gas. According to the present invention, an upper air valve 6 and a lower air valve 7 are respectively provided on the upper chamber seat 2 and the supporting mold 1, so that the sealing cavity formed by the supporting mold 1 and the upper chamber seat 2 can be vacuumized or inflated. Easy to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com