Unpowered quantitative unloading valve

A discharge valve and power technology, applied in the field of non-powered quantitative discharge valve, can solve problems such as power consumption, achieve the effects of controlling production costs, reducing energy consumption, and scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

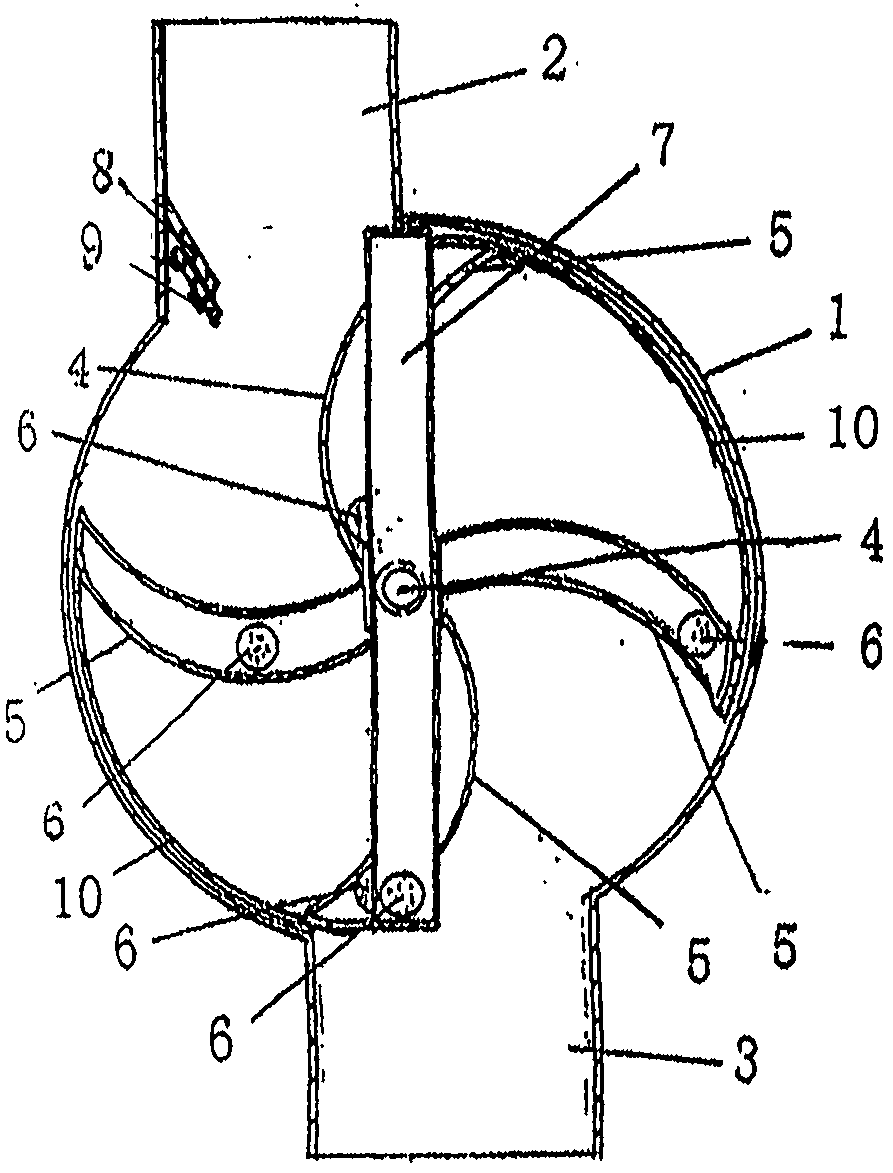

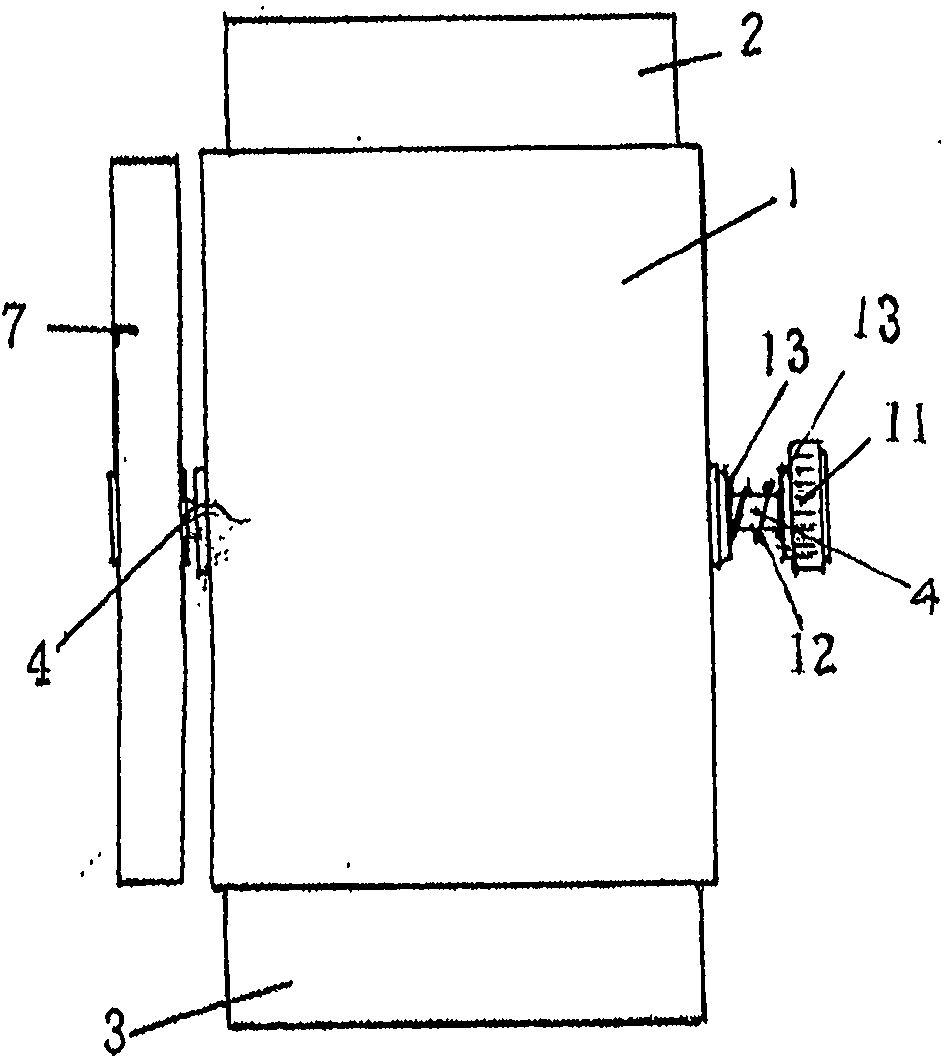

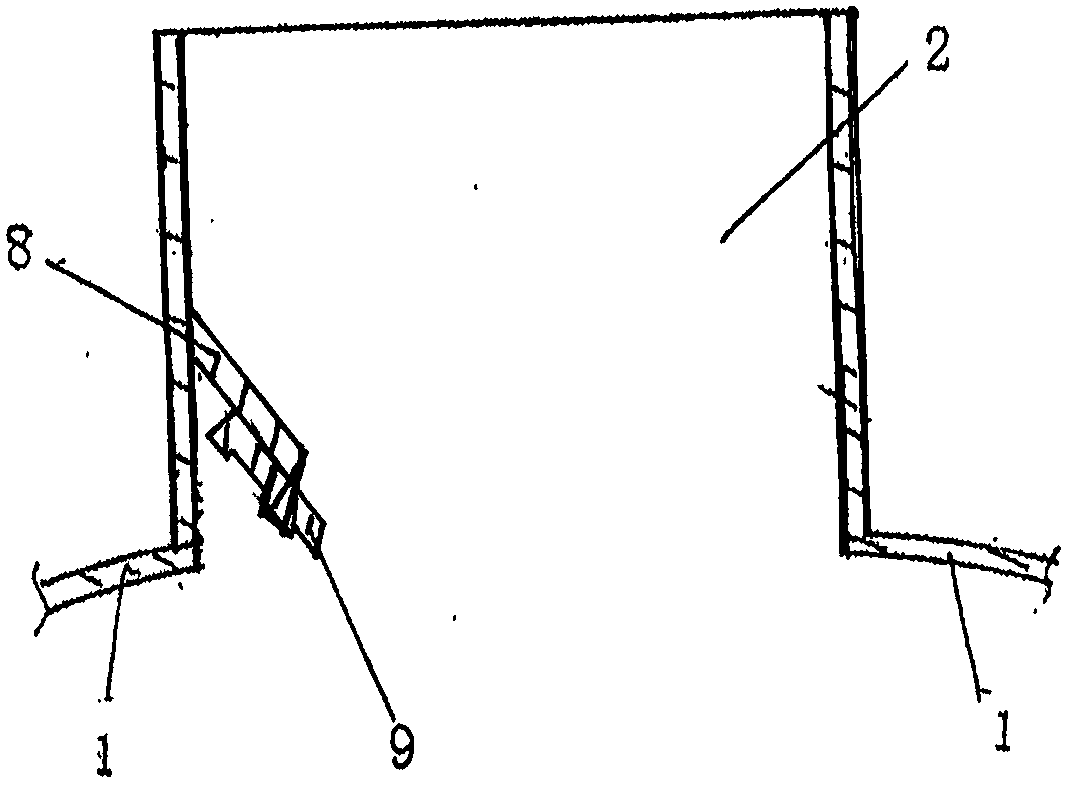

[0013] figure 1 , 2 . As shown in 3: the unloading valve is provided with a feed port 2 on the upper side of the circular valve body 1, and a discharge port 3 on the other side below; four hollow curved arc stops are evenly distributed on the middle rotating shaft 4 The material plate 5 and the outer end of the rotating shaft 4 are equipped with a counterweight cylinder 7 that rotates with the rotating shaft 4, and the four hollow curved arc baffle plates 5 and the counterweight cylinder 7 are equipped with a counterweight body 6; There is an inclined block 8 on the inner side of the upper side, and an anti-blocking scraper 9 that can slide up and down and be movable is installed on the lower side; four hollow curved arc baffles 5, two of which correspond to the outer side of the neutral block are closed plates 10, This constitutes an automatic rotating impeller structure in which the integral baffle plate can automatically unload materials in two neutral positions and block ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap