Method for strengthening insulation protection net in unlined tunnel

A technology for protective nets and tunnels, applied in tunnels, shaft linings, tunnel linings, etc., can solve the problems of fiber loss and strength, and achieve the effects of improving service life and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

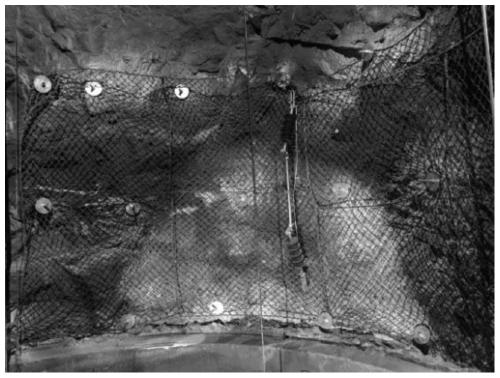

[0025] Embodiment 1, use the anchor backing plate to The insulation protection net is reinforced in the tunnel

[0026] The materials used are as follows:

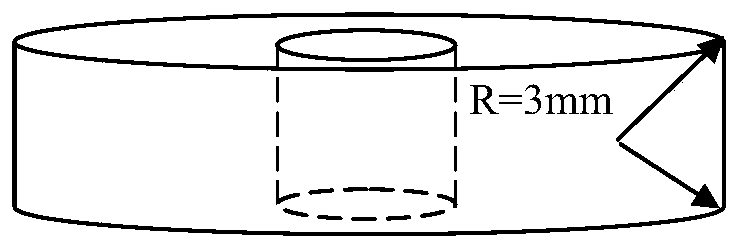

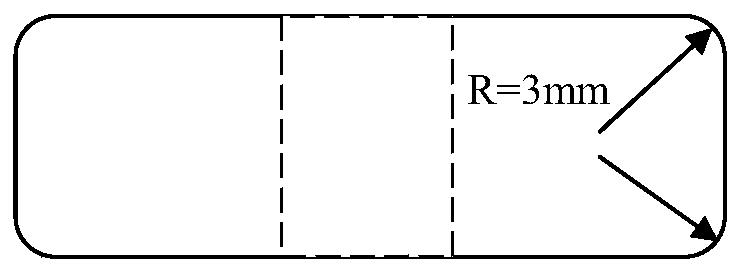

[0027] Anchor plate, the schematic diagram of which is shown in figure 1 As shown, it is made of galvanized steel sheet in a circular shape with an outer diameter of 180mm, an inner diameter of 25mm, and a thickness of 10mm, and the upper and lower surfaces have the same chamfer as the sides, and the radius of the chamfer is 3mm, Such as figure 2 shown.

[0028] Bolt: Hollow full-length grouted bolt is used, and the anti-corrosion adopts hot-dip galvanizing process. The diameter of the bolt is 25mm, and the length is 1-2.5m (including the exposed section). The specific design length is determined according to the test report of the surrounding rock stress circle.

[0029] Suture rope: use diameter 9mm The rope is used as a sewing rope.

[0030] Auxiliary bolt: used to make the protective net better cling to the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com