Gas film damping fan blade with vibration absorption sheet covered by throttling orifices

A technology of fan blades and orifices, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve the problem of lack of vibration damping mechanism for wide-chord fan blades and fan blade vibration , fan blade fatigue failure and other problems, to achieve obvious vibration reduction effect, reduce vibration level, and reduce structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

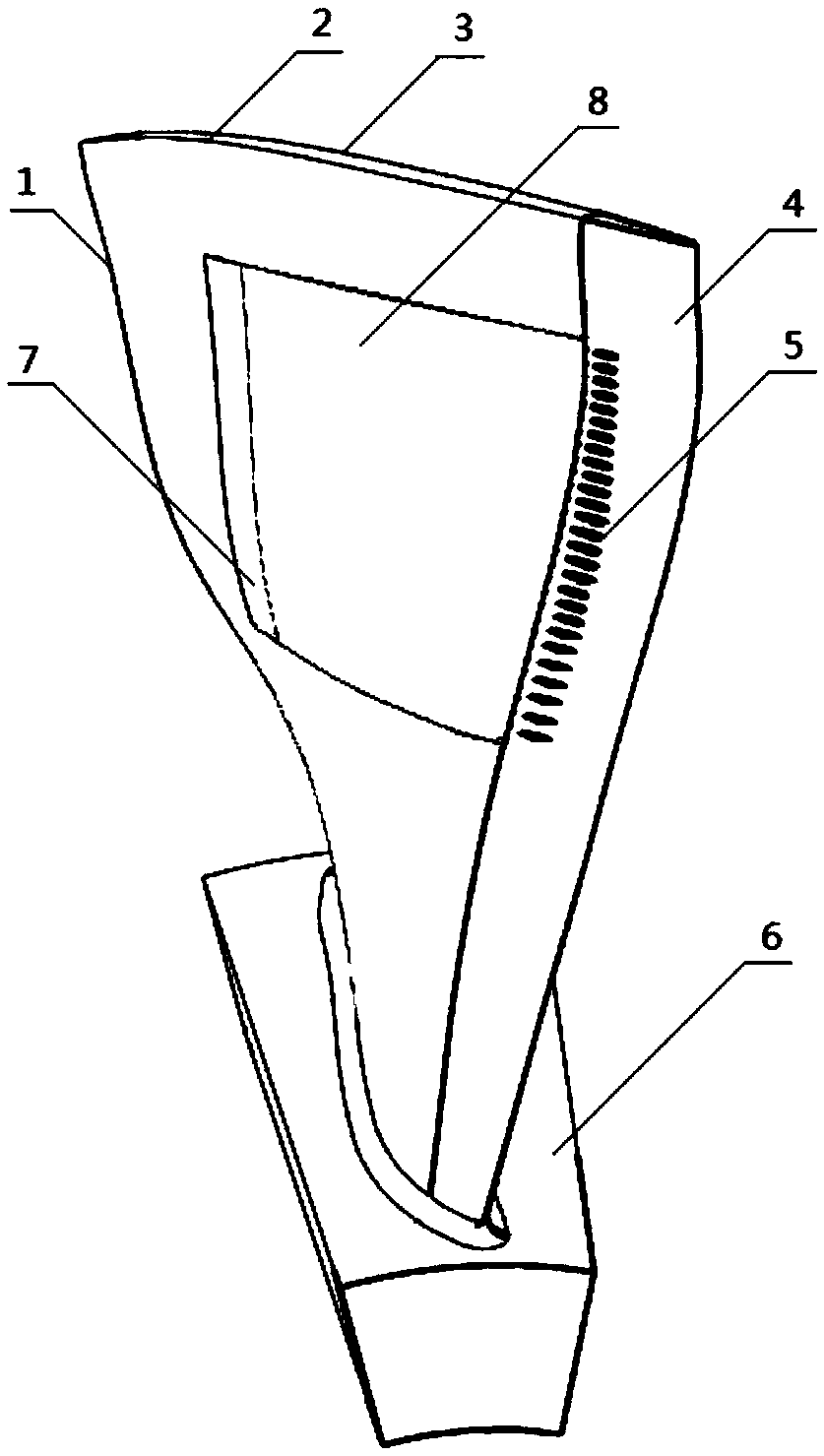

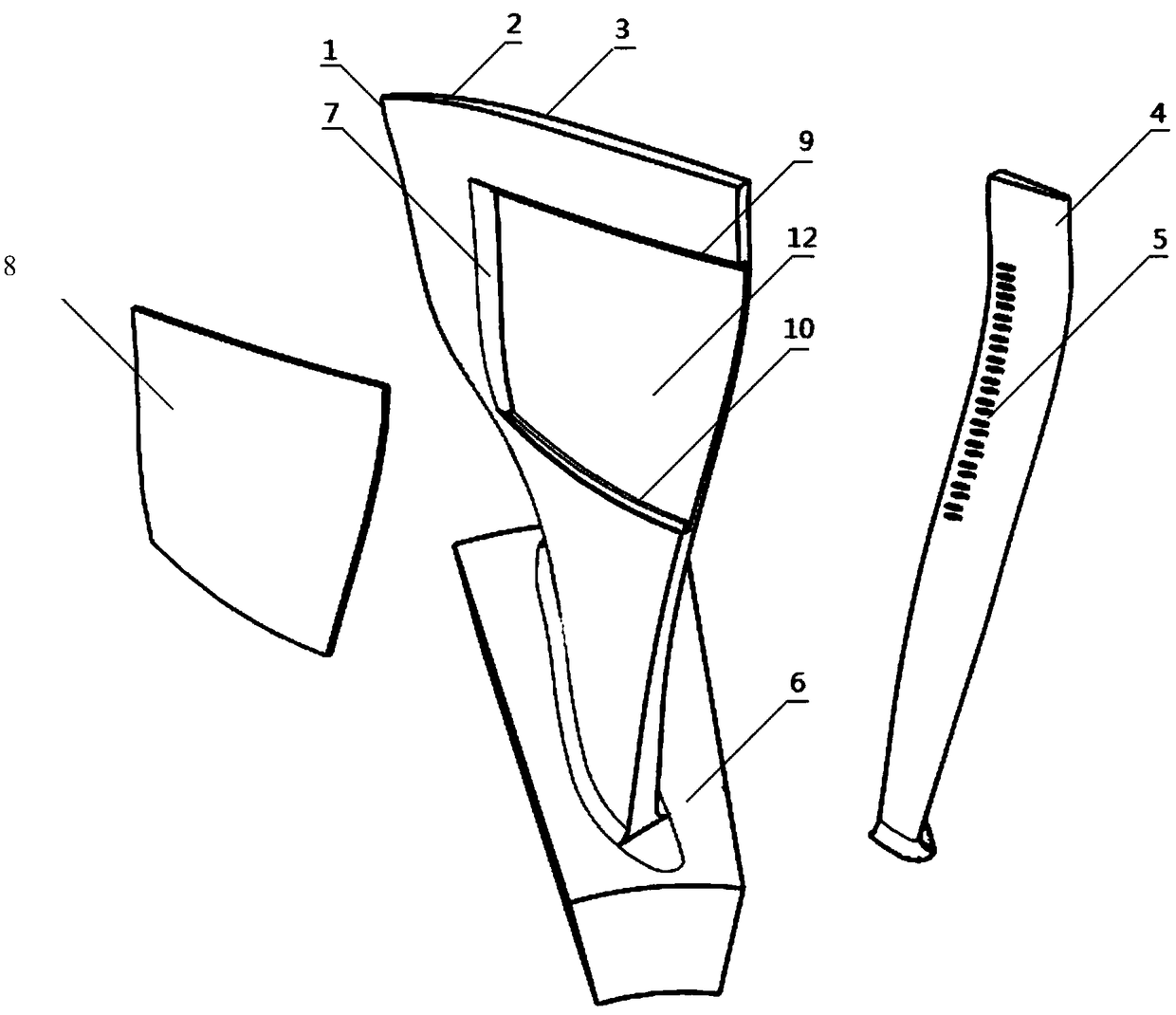

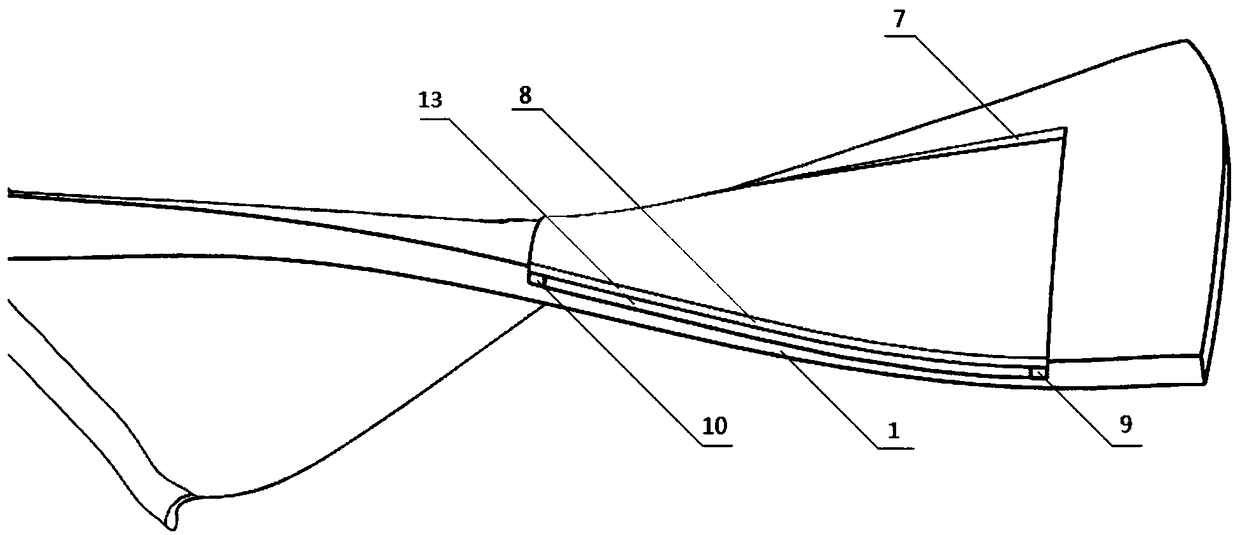

[0027] The air film damping fan blade provided by the present invention with an orifice covered with a shock-absorbing thin plate will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0028] Such as figure 1 — image 3 As shown, the air film damping fan blade with a throttle hole covered with a vibration-absorbing thin plate provided by the present invention includes a blade body 1, a vibration-absorbing thin plate 8, a blade leading edge 4, and a blade disc 6; wherein the blade body 1 is a large-sized wide chord without a shoulder The fan blade structure is composed of the blade back 2 and the blade pot 3 through diffusion welding, and the lower end is fixed on the blade disc 6; in the middle of the blade back 2, an open cavity 12 is formed extending from the front edge to the rear edge of the blade body , the upper and lower ends of the open cavity 12 are respectively equipped with an upper support 9 and a lower support 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com