Method for preventing looseness through bolt length-diameter ratio

A technology of length-to-diameter ratio and bolts, which is applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems that the length of bolts is not specified or reflected, so as to ensure the anti-loosening effect, reduce the difficulty of processing, and ensure the operation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

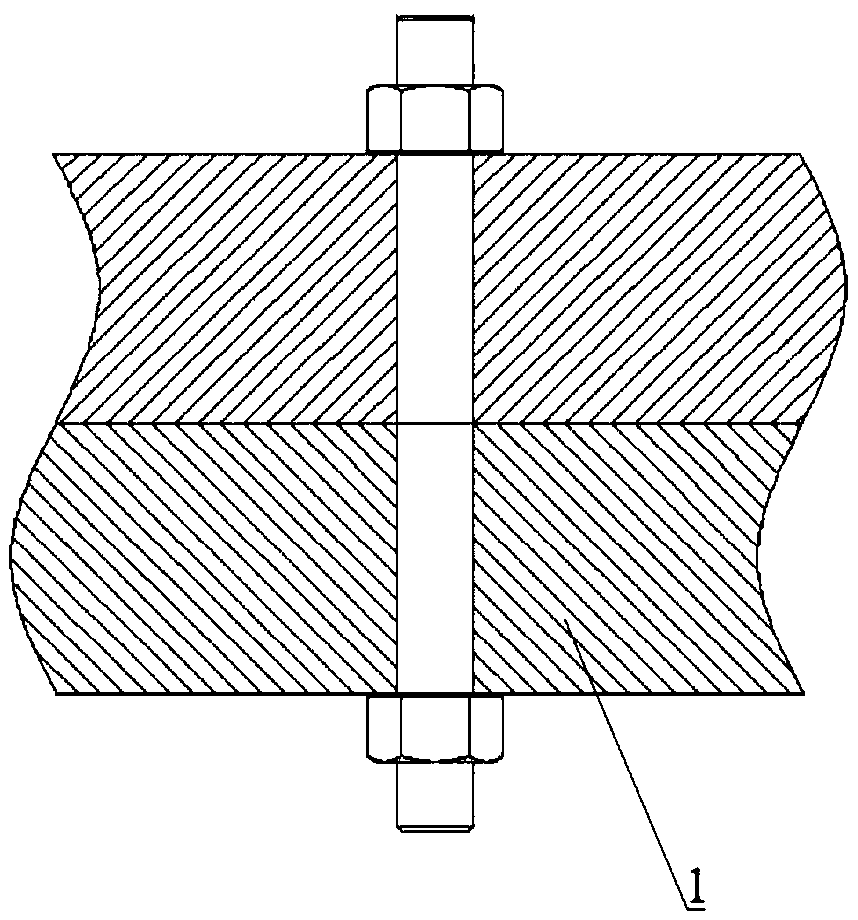

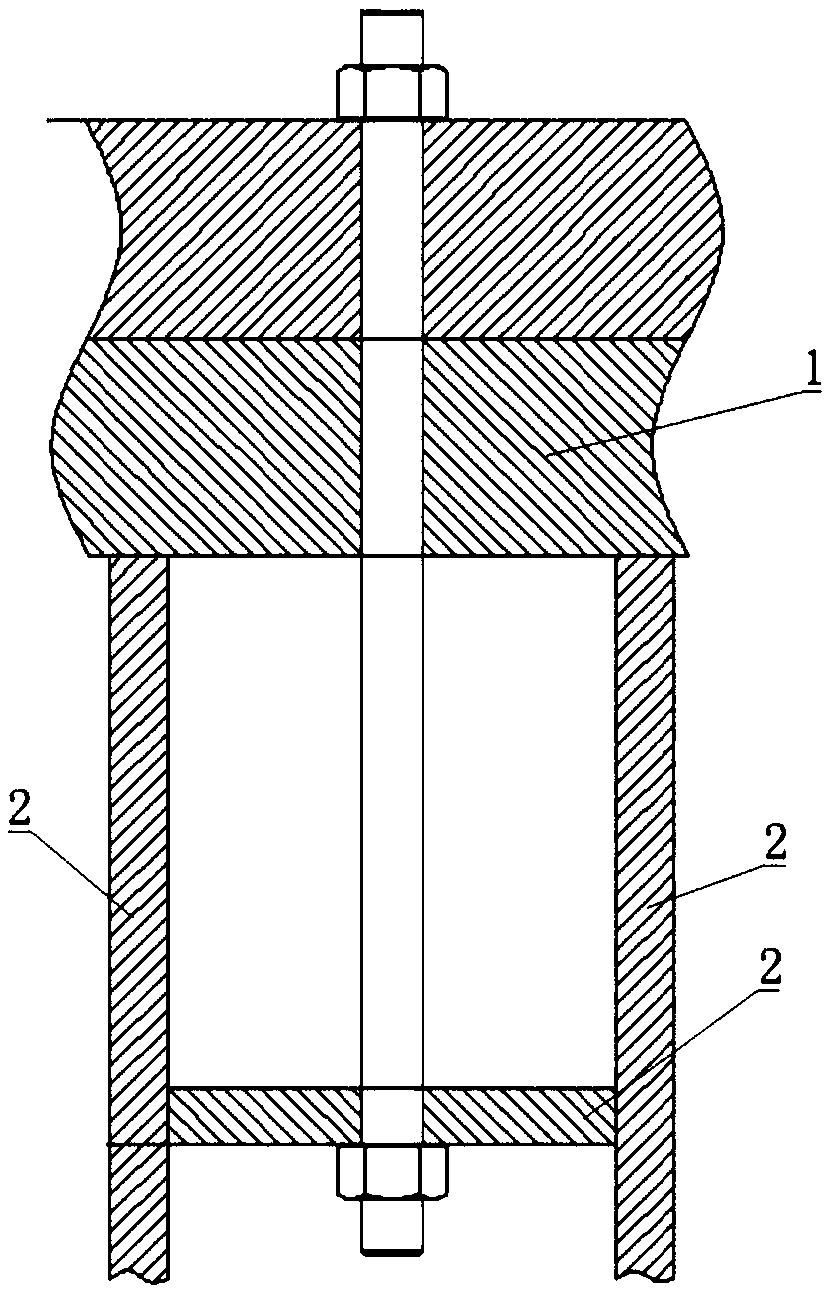

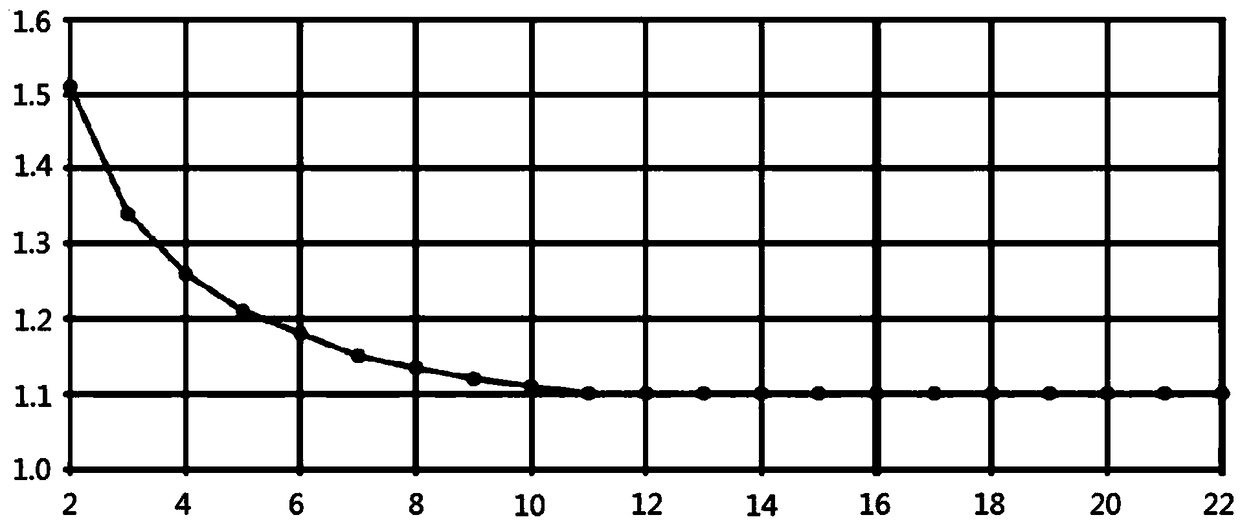

[0019] Such as Figures 1 to 2 As shown, a method of using bolt length-to-diameter ratio to prevent loosening is achieved by changing the bolt installation environment to adjust the effective length of bolt installation and adjusting the bolt length-to-diameter ratio to achieve the purpose of bolt loosening during use. The effective length of the installation bolt refers to the bolt tightness The absolute thickness of the solid workpiece.

[0020] In the example figure 2 The bolts in the figure change the effective length of the bolts installed on the workpiece 1 by increasing the support plate 2 to enhance the anti-loosening performance. The start and end of the effective length are represented by A in the figure. In this embodiment, this method is used to illustrate a specific implementation of the method in the present invention. Situation, other similar methods of using the present invention to enhance the anti-loosening performance of bolts all belong to the protection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com