Automatic Method of On-line Detection and Control of Weft Slant of Cloth

A cloth and weft skew technology, which is applied in the field of cloth weft skew online detection and control, can solve the problems of narrow range of weft skew, input errors, large errors, etc., and achieve the effects of improving production efficiency, reducing the amount of calculation, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The features of the present invention and other relevant features are described in further detail below through the embodiments, so as to facilitate the understanding of those skilled in the art:

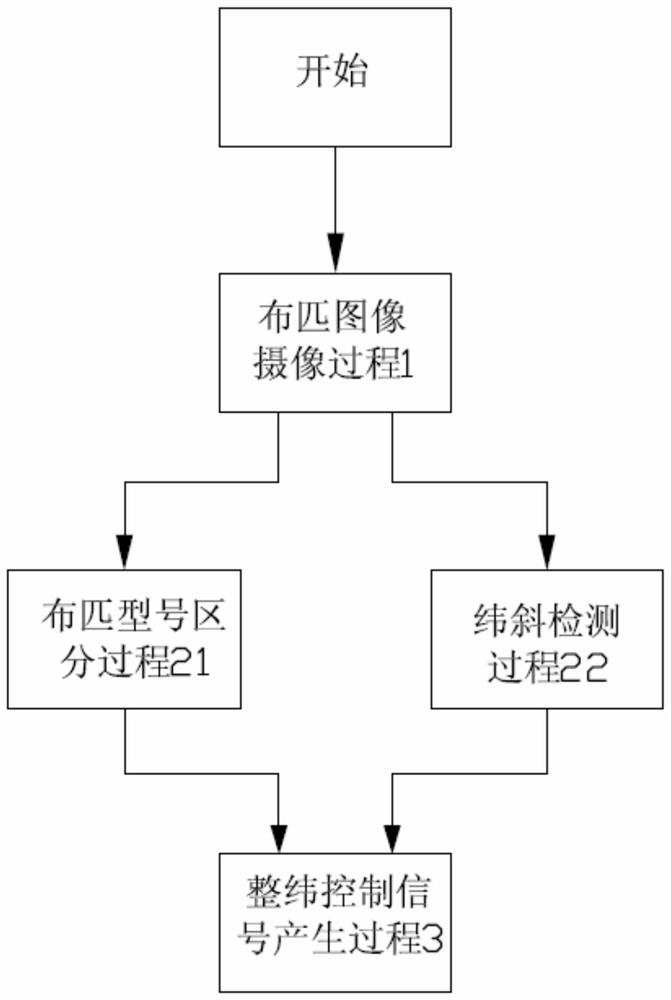

[0029] Such as Figure 1 to Figure 3 As shown, the automatic method for cloth weft skew online detection and control is characterized in that it includes a cloth image camera process 1, a cloth model distinction process 21, a weft skew detection process 22, and a whole weft control signal generation process 3, wherein,

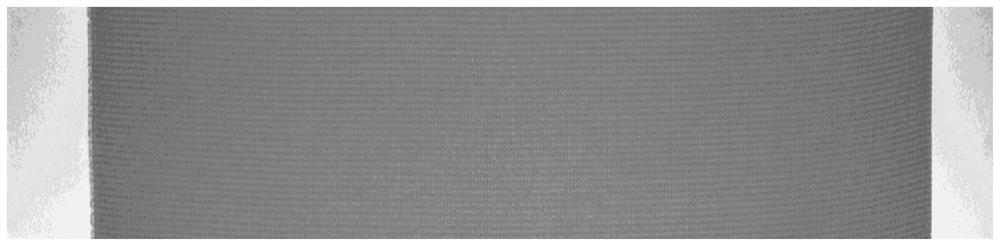

[0030] Described cloth image photographing process 1 is specifically as follows: control module carries out real-time photographing to online cloth by photographing module, and carries out data storage;

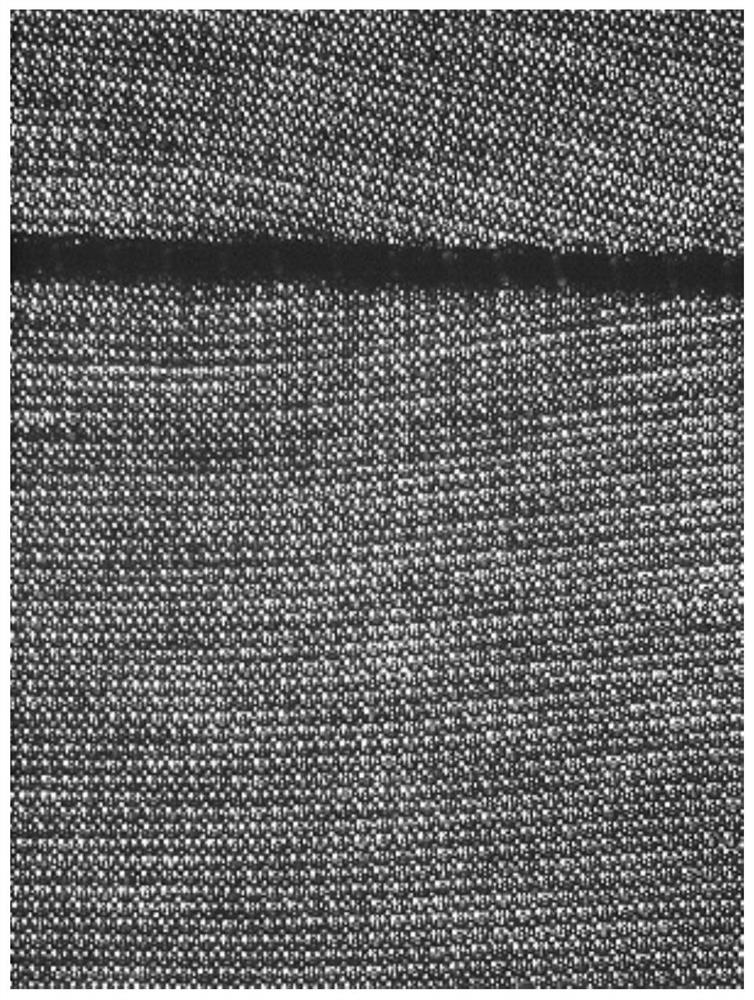

[0031] Described cloth model distinguishing process 21 is specifically as follows: control module judges current cloth kind according to cloth image, if judge current cloth kind when being pure color cloth, extract the characteristic data of current pure col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com