Integrated manufacturing method for electric power Ethernet informatization marks

A production method and identification technology, which are applied to record carriers, identification devices, and instruments used in machines, can solve the problems of inconsistent data, low production capacity, and high pollution, and achieve the effect of solving the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

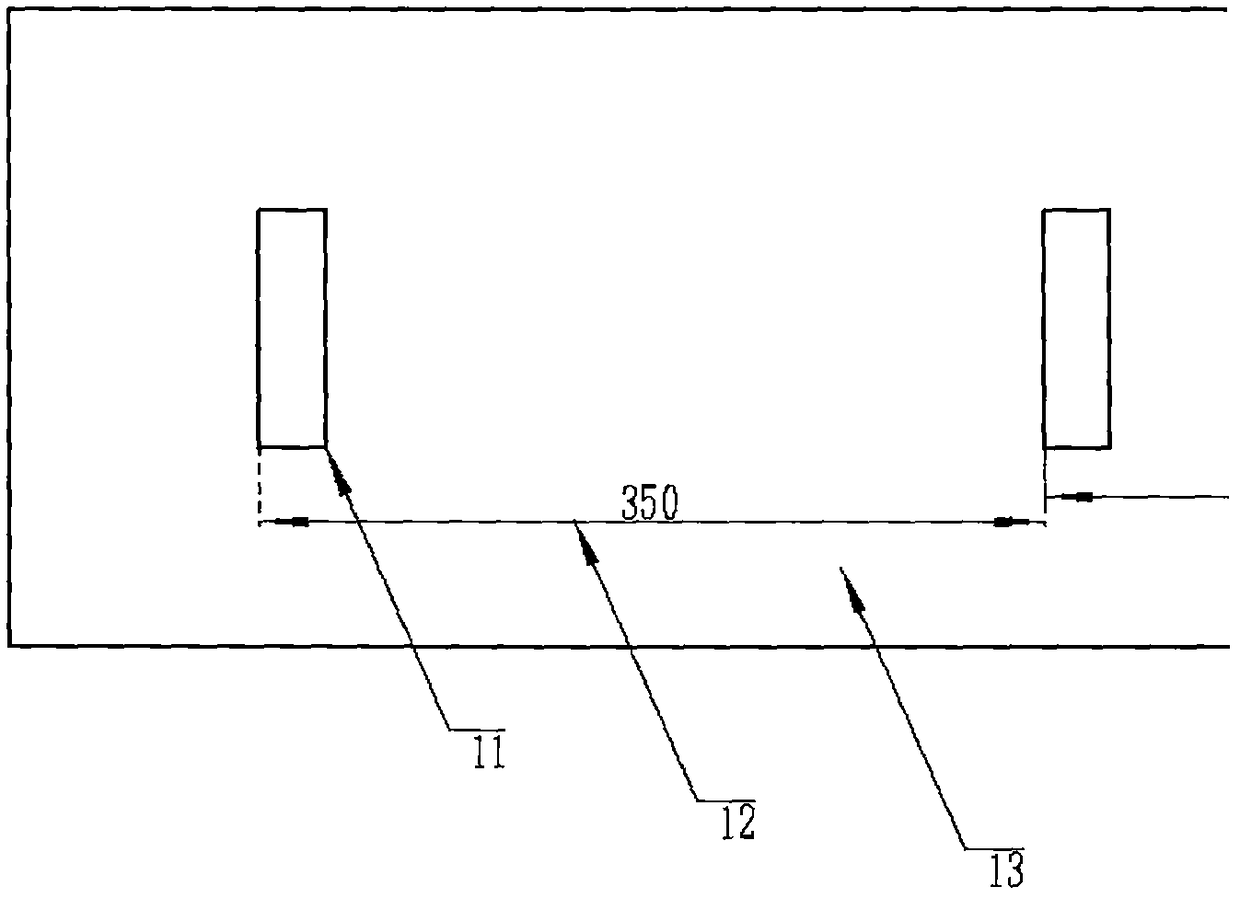

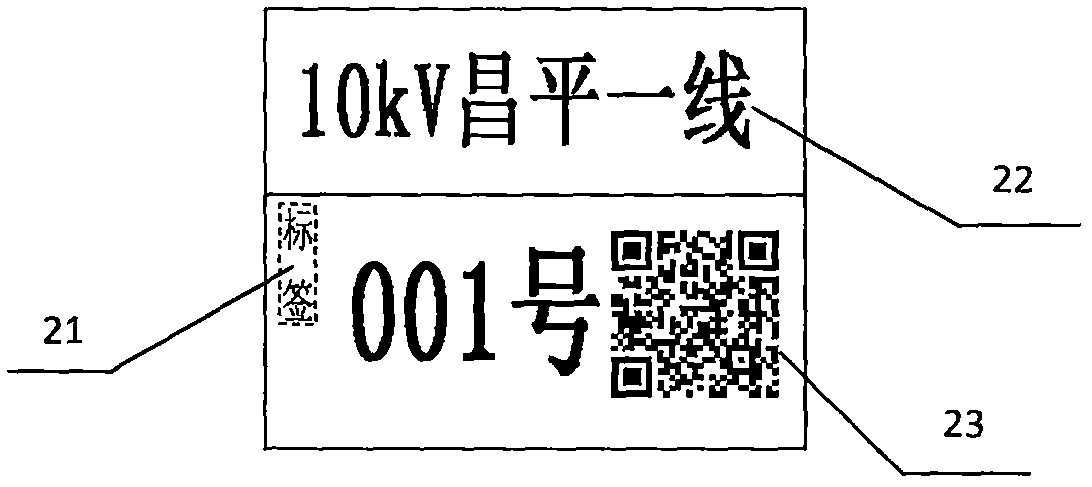

[0032] Such as figure 2 As shown, the ultra-thin 0.25mm flexible UHF electronic label and 0.135mm thick thermal transfer tape are laminated to form an IoT information tape, and then passed through the device equipped with a radio frequency read-write module and a thermal transfer print head Print power operation identification information and QR code information to form an integrated production and one-time molding process. This process effectively solves the problems of high energy consumption, high pollution, and low production capacity in the traditional stainless steel, aluminum alloy, and enamel label production process, and solves the cumbersome process brought about by batch production and installation of electronic labels and two-dimensional code labels. The cost and labor cost of batch installation of fixed brackets solves the problem of batch production and installation data inconsistency, and at the same time solves the unified and standardized construction of elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com