Vacuum temperature control test chamber

A test box and vacuum technology, which is applied in the direction of laboratory appliances, heating or cooling equipment, shells or chambers, etc., can solve the problems of loss, poor heat exchange effect, inaccurate performance test results, etc., to speed up heat exchange, The effect of enhancing the heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

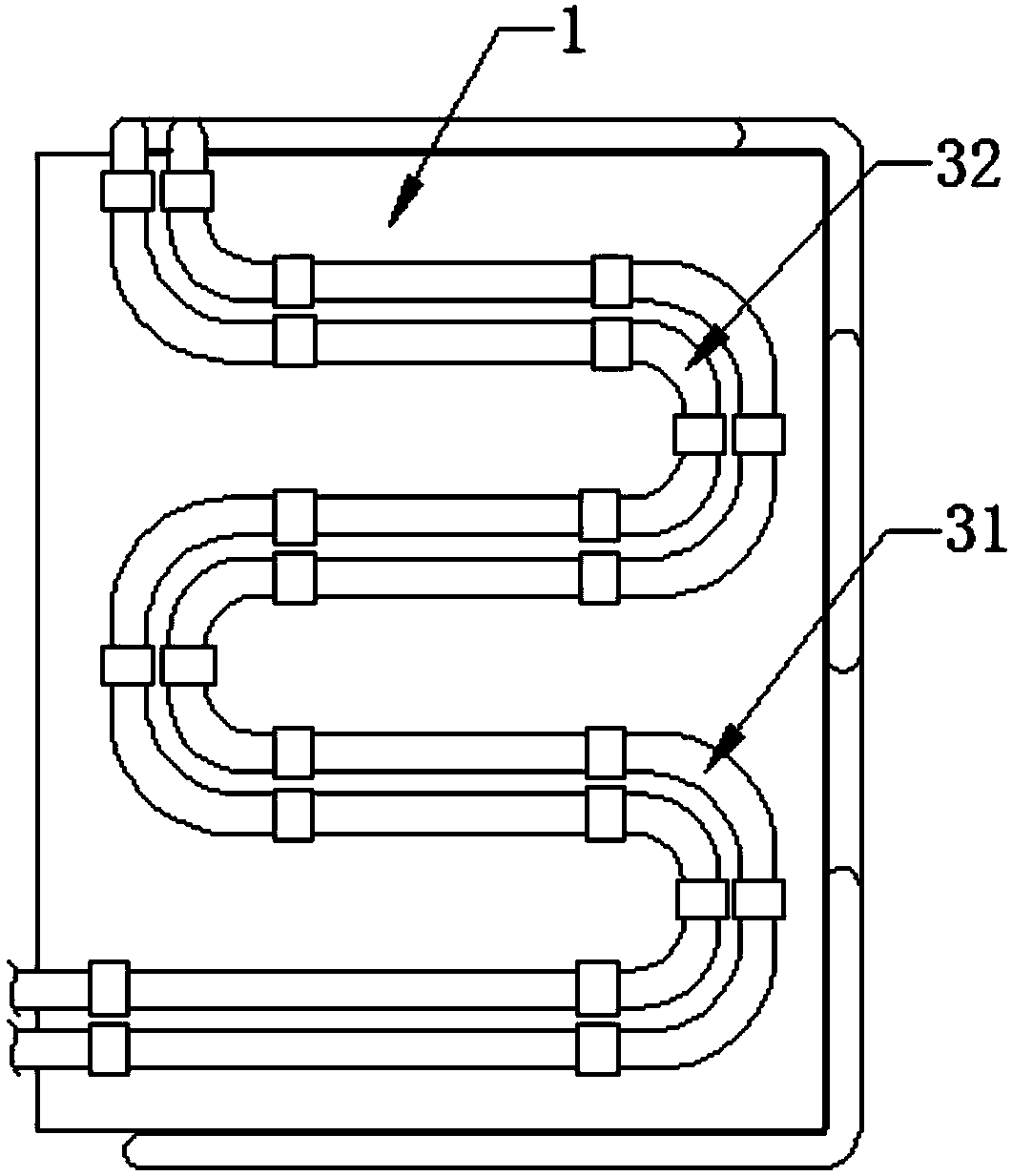

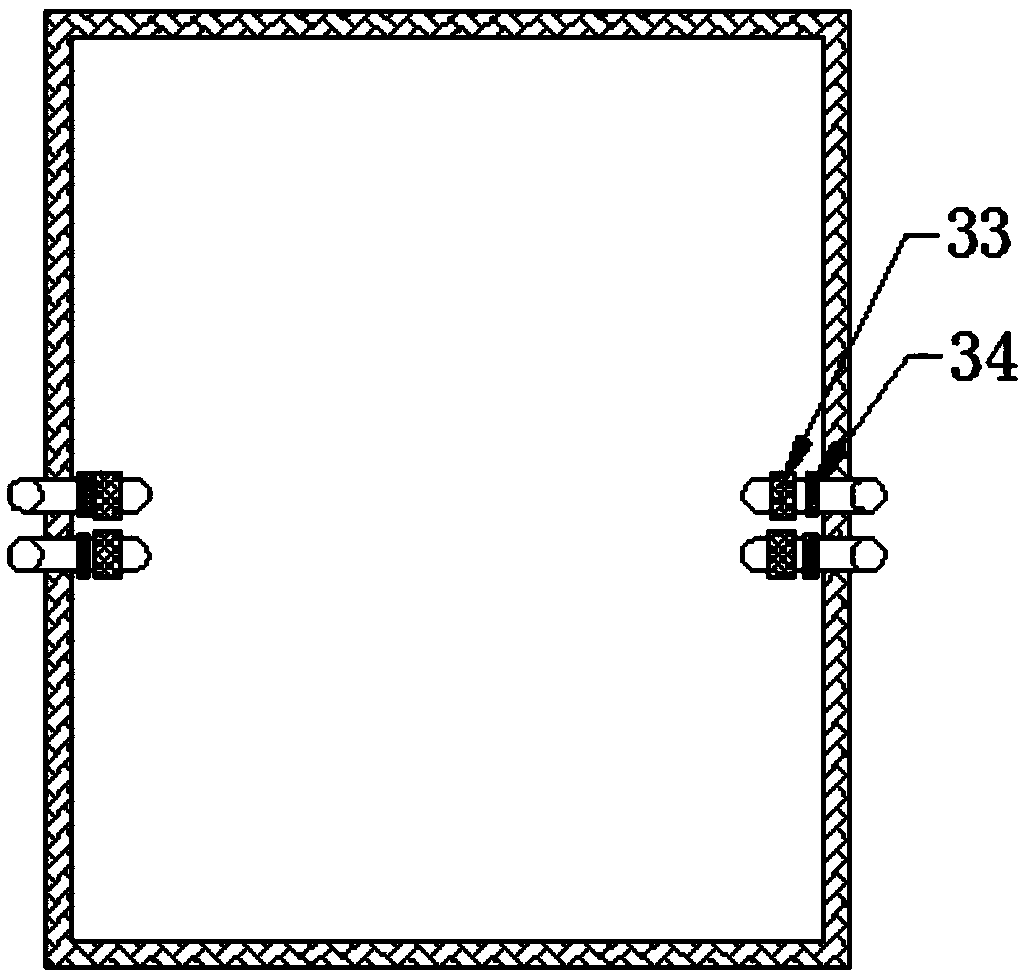

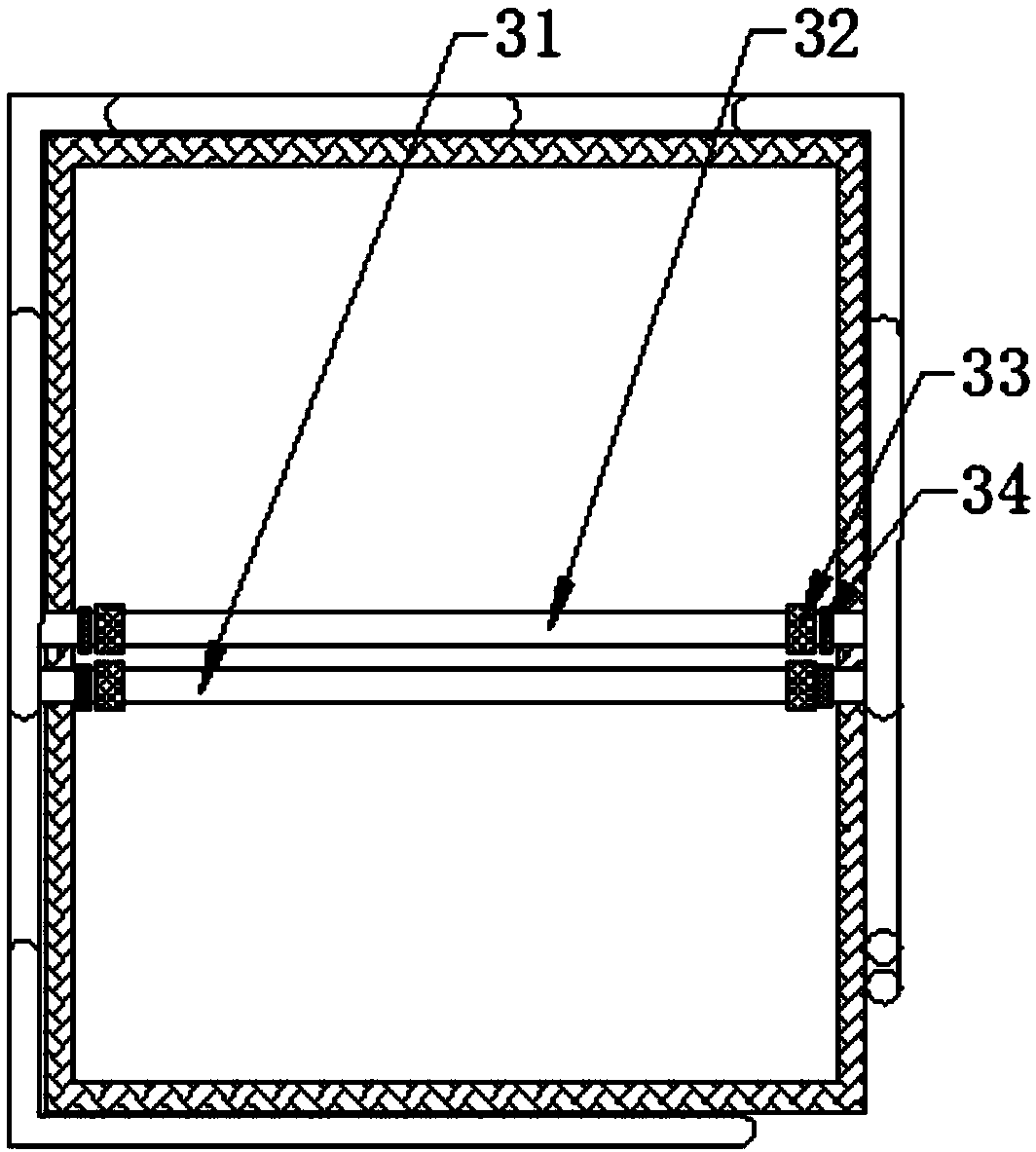

[0047] like figure 1 , Figure 12 As shown, a vacuum temperature control test box includes a temperature control sealing box 1, the temperature control sealing box 1 is connected with a temperature regulating box 2 and an air pressure regulating device, and the box body of the temperature control sealing box 1 is sequentially arranged from inside to outside A box inner shell, an insulating layer 4 and an outer box shell 5 are provided, the key of which is that a door 10 is installed on one side wall of the temperature-controlled sealed box 1, and a peripheral thermostatic tube is arranged in the insulating layer 4 , all of the peripheral thermostatic tubes are closely attached to the box inner shell; the peripheral thermostatic tubes are evenly distributed in an S shape on the box inner shells of the other five box surfaces of the temperature control sealed box 1; The peripheral thermostatic tube is bonded to the inner wall of the temperature-controlled sealed box 1 through ...

Embodiment 2

[0056] Embodiment 2: as image 3 As shown, the built-in thermostatic tube may be a straight tube, and the straight tube connects the third nozzles of the two relative three-way pipes in a straight line;

Embodiment 3

[0057] Embodiment 3: as Figure 4 As shown, the built-in thermostatic tube protrudes toward the top of the temperature-controlled sealed box 1, and the protruding part is close to the top of the temperature-controlled sealed box 1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com