Portable large pipeline welding butting device and method of use

A convenient, pipeline-based technology, which is applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems affecting the quality of pipeline welding, the amount of pipeline error exceeding the standard, pipeline production errors and transportation deformation, etc., to achieve convenient production and operation. Simplicity, the effect of reducing construction resources and piping adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is further illustrated below by specific examples.

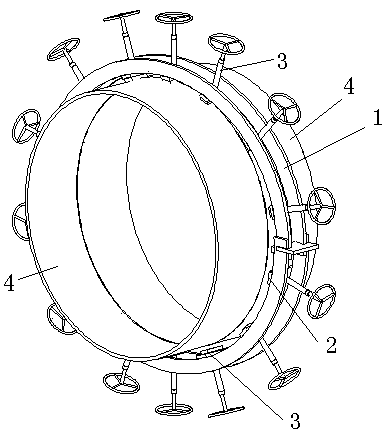

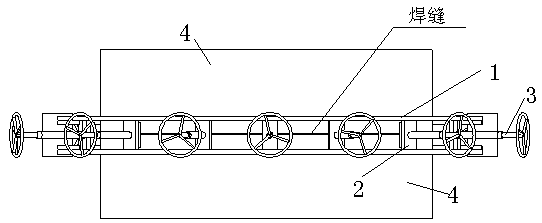

[0017] Such as figure 1 , figure 2 As shown, a portable large-scale pipeline welding counterpart device includes an annular cage 1, a pressure plate 2 and a locking bolt 3, wherein the annular cage 1 is sleeved at the butt joint of two pipelines 4, and the pressure plate 2 has Multiple pieces are evenly distributed on the inner side of the ring cage 1, the inner surface of the pressure plate 2 is respectively against the outer walls of the two pipes 4, and the outer side of the pressure plate 2 is provided with locking bolts 3; the locking bolts 3 pass through the ring cage 1, It is connected with the annular cage 1 through a threaded through hole, and the locking bolt 3 is rotated so that the pressure plate 2 is tightly pressed against the outer wall of the pipe 4 .

[0018] The use method of the portable large-scale pipeline welding counterpart device includes

[0019] Step 1. Adjust the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com