Asymmetric-transmission non-woVen composite material and preparation method thereof

An asymmetric transmission, non-woven material technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of not being able to better serve the comfort of absorbent sanitary products, and achieve fast horizontal diffusion, thin thickness, and good The effect of process flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

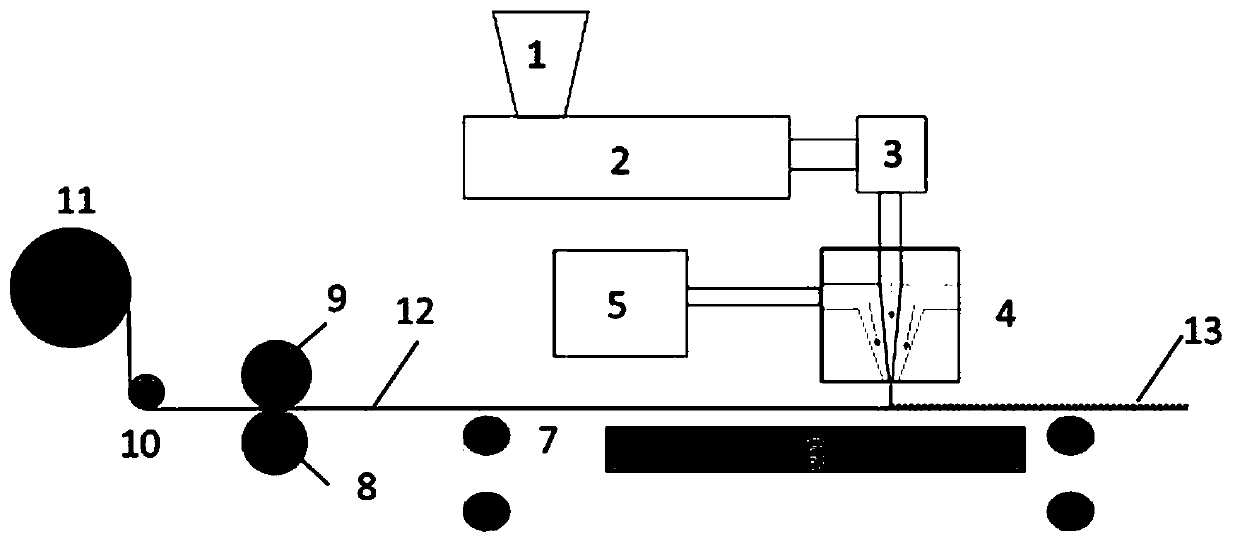

[0024] A method for preparing a non-woven composite material with asymmetric transmission in this embodiment, the steps are:

[0025] (1) The preparation of the vertical permeable layer will contain hot-melt fiber ES fiber, the mixing ratio of ES fiber is 60%; the fiber fineness is 1.5 denier, and the fiber length is 51mm. It is carded into a web by dry method (for the specific process, refer to Chapter 3, (Short Fiber Web Forming Process and Principle) and Chapter 6, (Thermal Bonding Process and Principle) of "Nonwovens" for the specific process, and it is made into a gram after drying with hot air. Weight 12g / m 2 The non-woven material is then controlled to a thickness of 5 mm with rolls, and the temperature of the rolls is 90°C.

[0026] (2) The online composite process is adopted, and the hot air nonwoven fabric reaches the bottom of the spinneret hole of the meltblown die head by using the conveying curtain.

[0027] (3) For the preparation of the horizontal diffusion l...

Embodiment 2

[0030] A method for preparing a non-woven composite material with asymmetric transmission in this embodiment, the steps are:

[0031] (1) The preparation of the vertical permeable layer will contain hot-melt fiber PE / PP sheath-core fiber, the mixing ratio of PE / PP sheath-core fiber is 60%, and the fiber of the PEG / PP melt-blown ultrafine fiber material The diameter distribution is below 800nm, 800-2000nm and above 2000nm. The number of fibers in the three distributions is counted as 100 parts, of which the number of fibers below 800nm is 10 parts, the number of fibers above 2000nm is 18 parts, and the balance is 800-2000nm in diameter. of fiber. The fiber fineness is 1.5 denier, and the fiber length is 51 mm. Combed into a net by dry method, and dried with hot air to make a grammage of 17g / m 2 The non-woven material is then controlled to a thickness of 5mm with a roller, and the temperature of the roller is 100°C.

[0032] (2) The online composite process is adopted, and ...

Embodiment 3

[0036] A method for preparing a non-woven composite material with asymmetric transmission in this embodiment, the steps are:

[0037] (1) The preparation of the vertical permeable layer will contain hot-melt fiber PE / PP sheath-core fiber, the mixing ratio of PE / PP sheath-core fiber is 60%, and the fiber of the PEG / PP melt-blown ultrafine fiber material The diameter distribution is below 800nm, 800-2000nm and above 2000nm. The number of fibers in the three distributions is counted as 100 parts, of which the number of fibers below 800nm is 10 parts, the number of fibers above 2000nm is 42 parts, and the balance is 800-2000nm in diameter. The fiber; the fiber fineness is 1.5 denier, and the fiber length is 51mm. Use dry carding to form a web (for the specific process, refer to "Nonwovens" Chapter 3 Short Fiber Web Forming Process and Principle and Chapter 6 Thermal Bonding Process and Principle, which will not be introduced too much here), after hot air drying. Gram weight 17g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com