Fire cabinet for first-line construction site with open water supply

A technology for construction sites and fire cabinets, which is applied in general water supply conservation, construction, and water supply installations. It can solve problems that affect construction efficiency, inconvenient water supply, and waste of time, so as to increase the rainwater collection area, ensure smooth pipelines, and improve collection. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

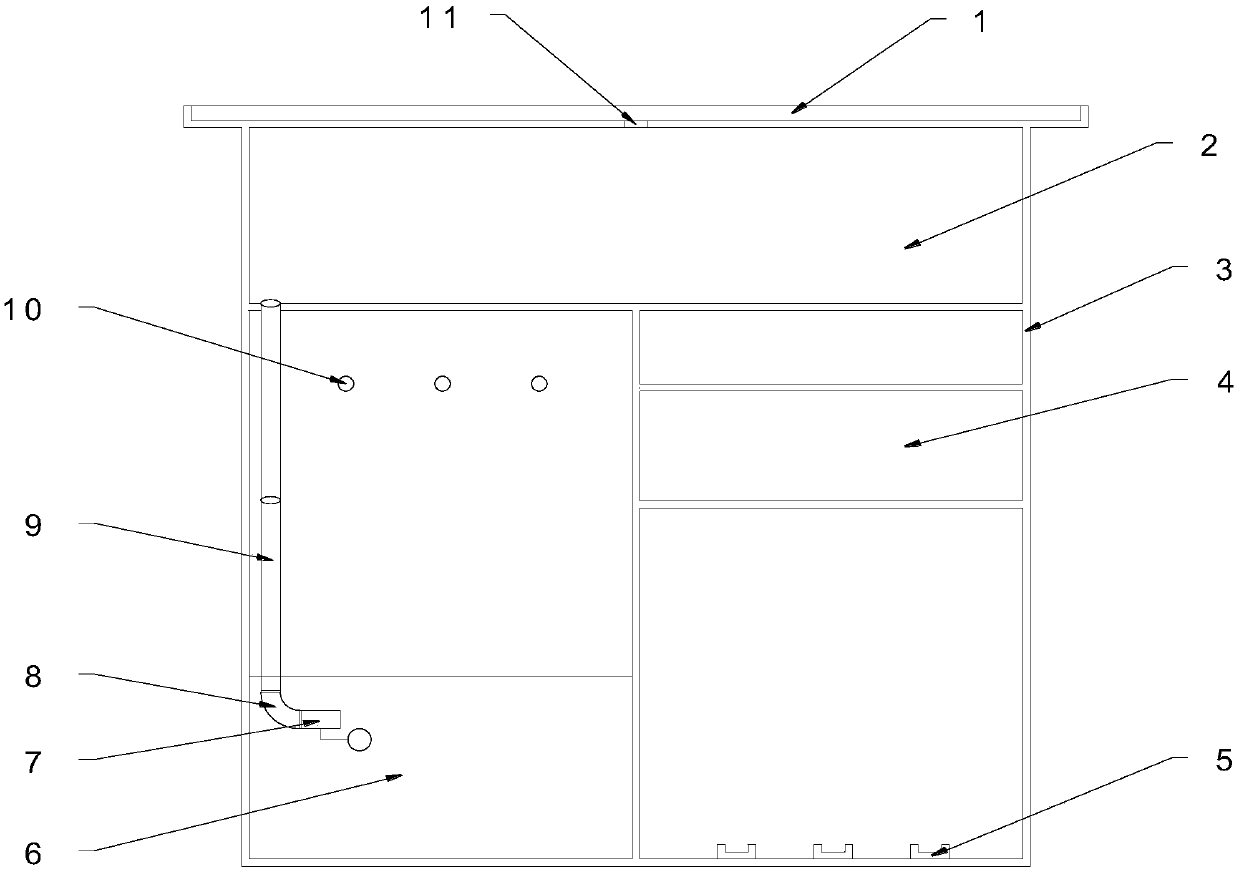

[0029] see Figure 1~2 A first-line construction site fire cabinet for open water supply, comprising a cabinet body 3, the cabinet body 3 is provided with a storage bin 4, and the cabinet body 3 is provided with a ceiling 1, a top water tank 2 and a bottom open water tank 6 from top to bottom, The ceiling 1 is provided with a water inlet 11 communicating with the inner cavity of the top water tank 2, the top water tank 2 and the bottom open water tank 6 are connected through a pipe 9, and a 90-degree elbow 8 is provided directly below the lower opening of the pipe 9, and the 90-degree elbow is horizontal Port is provided with float valve 7, and float valve 7 is positioned at bottom open water tank 6, and can close float valve water inlet 19 along with bottom open water tank 6 water level rises, opens float valve water inlet 19 with bottom open water tank 6 water level declines.

[0030] In this example, rainwater is collected through the roof 1 and introduced into the top wate...

Embodiment 2

[0032] see Figure 1~2 A first-line construction site fire cabinet for open water supply, comprising a cabinet body 3, the cabinet body 3 is provided with a storage bin 4, and the cabinet body 3 is provided with a ceiling 1, a top water tank 2 and a bottom open water tank 6 from top to bottom, The ceiling 1 is provided with a water inlet 11 communicating with the inner cavity of the top water tank 2, the top water tank 2 and the bottom open water tank 6 are connected through a pipe 9, and a 90-degree elbow 8 is provided directly below the lower opening of the pipe 9, and the 90-degree elbow is horizontal Port is provided with float valve 7, and float valve 7 is positioned at bottom open water tank 6, and can close float valve water inlet 19 along with bottom open water tank 6 water level rises, opens float valve water inlet 19 with bottom open water tank 6 water level declines.

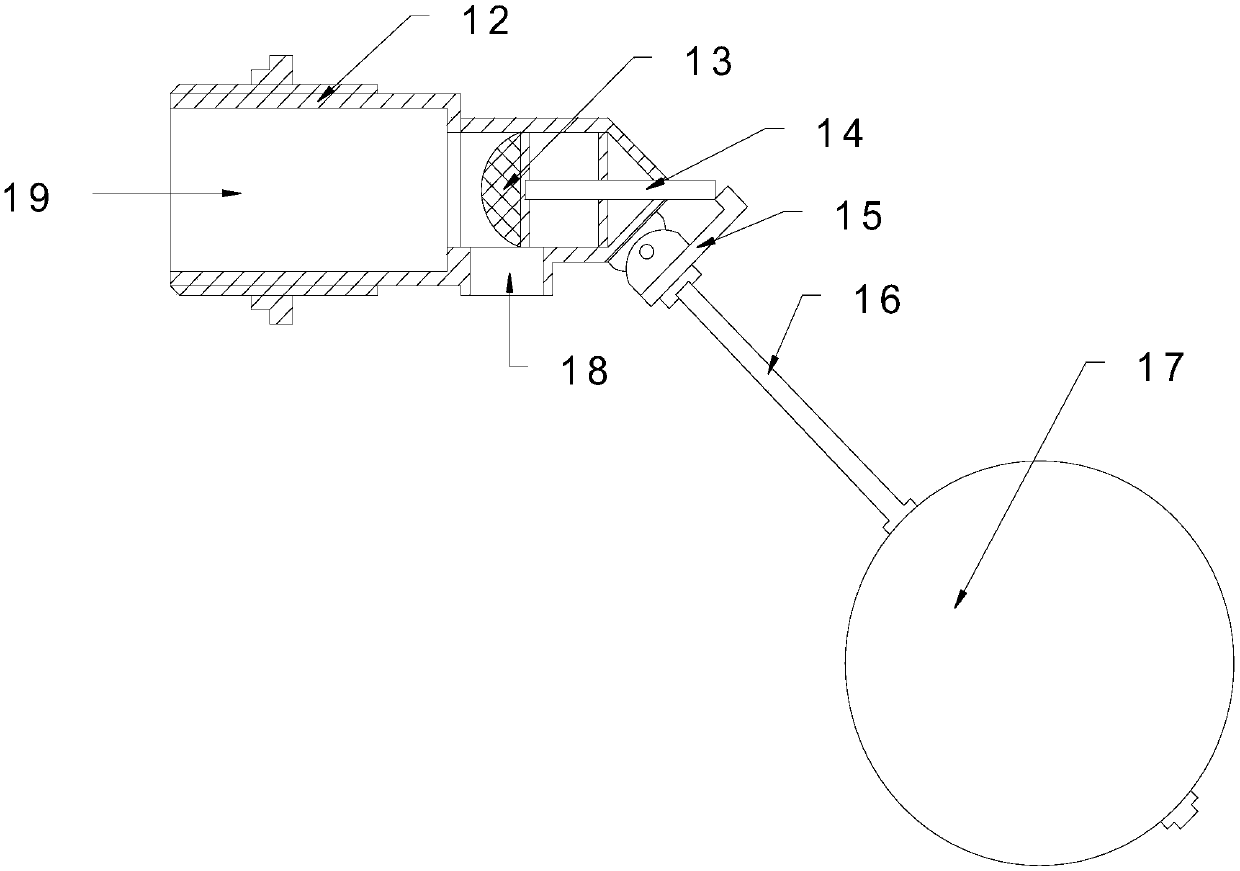

[0033] In this example, the ball float valve 7 includes a valve body 12, the ball float valve wate...

Embodiment 3

[0036] see Figure 1~2 A first-line construction site fire cabinet for open water supply, comprising a cabinet body 3, the cabinet body 3 is provided with a storage bin 4, and the cabinet body 3 is provided with a ceiling 1, a top water tank 2 and a bottom open water tank 6 from top to bottom, The ceiling 1 is provided with a water inlet 11 communicating with the inner cavity of the top water tank 2, the top water tank 2 and the bottom open water tank 6 are connected through a pipe 9, and a 90-degree elbow 8 is provided directly below the lower opening of the pipe 9, and the 90-degree elbow is horizontal Port is provided with float valve 7, and float valve 7 is positioned at bottom open water tank 6, and can close float valve water inlet 19 along with bottom open water tank 6 water level rises, opens float valve water inlet 19 with bottom open water tank 6 water level declines.

[0037] The four sides of the ceiling 1 are rolled up into a groove shape, and the four sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com