Storage type turbocharger

A turbocharger and turbine technology, which is used in machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of air intake airflow obstruction, reduce intake air flow velocity, etc., to improve air intake efficiency, simple and reasonable structure , Control convenient and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

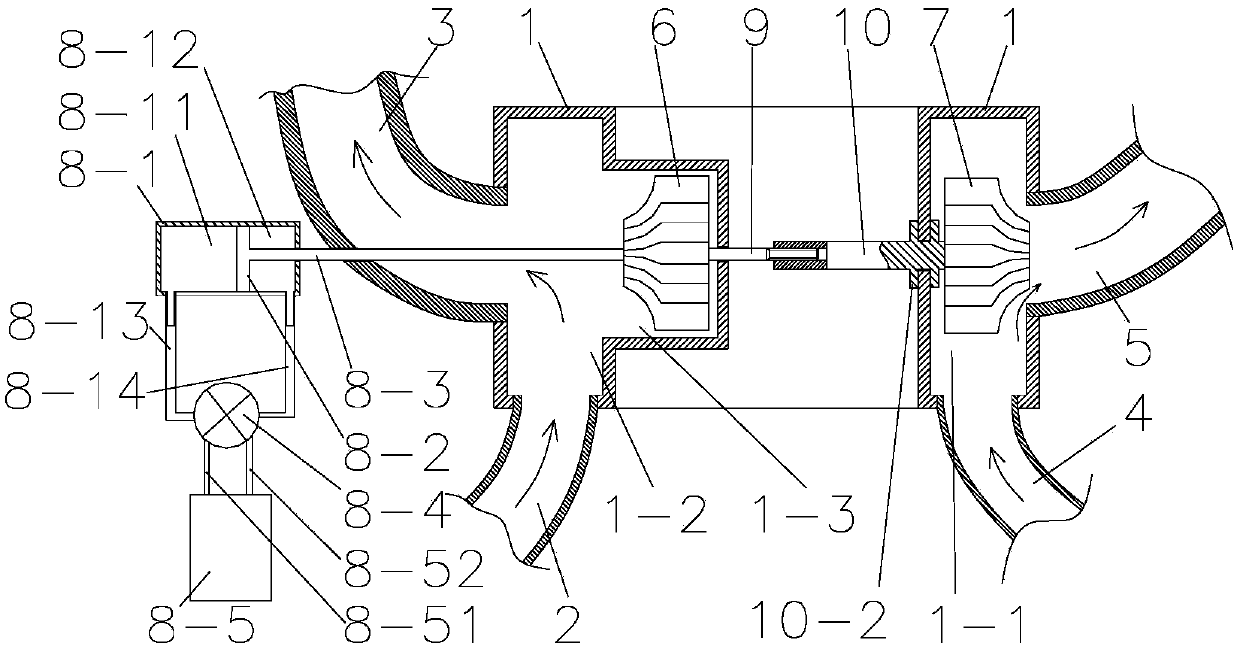

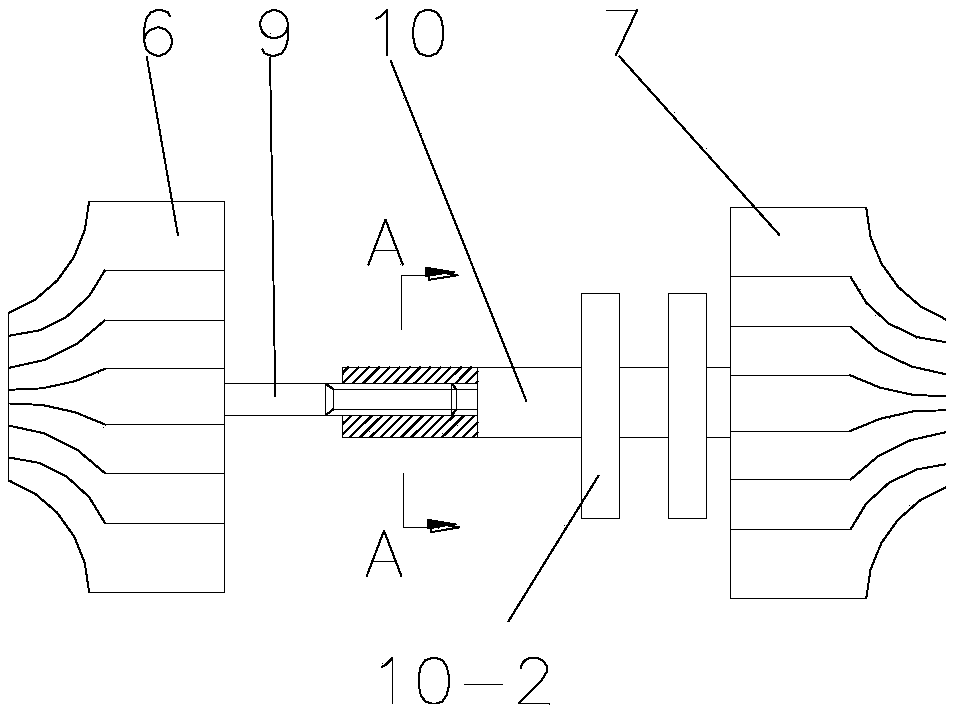

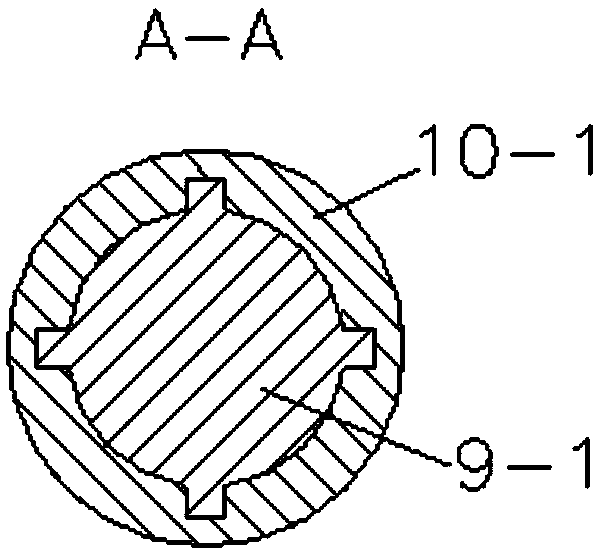

[0022] Such as figure 1 with Figure 4 As shown, a retractable turbocharger includes a housing 1, an intake turbine 6, an exhaust turbine 7, and a driving device. The housing 1 is provided with an exhaust passage 1-1, an intake passage 1- 2 and the intake receiving groove 1-3 communicating with the intake port 1-2, the intake port 1-2 has a front side intake port 2 and a rear side intake port 3, the exhaust port 1- 1 has a front exhaust port 4 and a rear exhaust port 5. The intake turbine 6 and the exhaust turbine 7 are respectively arranged in the intake port 1-2 and the exhaust port 1-1, the exhaust The turbine 7 is axially fixed, the intake turbine 6 and the exhaust turbine 7 rotate coaxially, and the driving device is used to drive the intake turbine 6 to slide between the intake duct 1-2 and the intake receiving groove 1-3 .

[0023] Such as Figure 1~7 As shown, the driving device includes a control cylinder 8-1, a control rod 8-3, a reversing valve 8-4, and a hydraulic pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com