Antibacterial biofilm composite microneedle and application thereof

A biofilm and anti-bacterial technology, applied in microneedles, needles, drug delivery, etc., can solve the problems of difficult to completely remove bacterial biofilm and wound healing, achieve good broad-spectrum and biocompatibility, and improve performance , the effect of a wide range of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

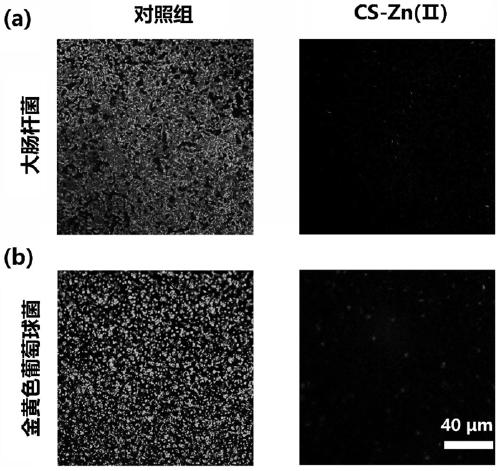

[0036] Embodiment 1 antibacterial biofilm composite microneedle

[0037] A kind of antibacterial biofilm composite microneedle, its preparation method comprises the following steps:

[0038] S1. Dissolve chitosan and zinc nitrate with a molecular weight of 50KDa in water (the quality of chitosan, the quality of zinc nitrate and the volume ratio of water are 0.3:2:50), vacuum defoaming, to obtain chitosan zinc nitrate compound solution;

[0039] S2. the chitosan zinc nitrate composite solution that step S1 obtains is 0.2mL / cm 2 Spread on the PDMS microneedle mold, evacuate to 0.06MPa, hold the pressure for 2 minutes, deflate, repeat 3 times, dry, and peel off to obtain the antibacterial biofilm composite microneedle; wherein, the microneedle body The length of the microneedle is 340 μm, the diameter of the top of the microneedle body is 250 μm, and the diameter of the bottom of the microneedle body is 25 μm.

[0040] The schematic diagram of the antibacterial biofilm composi...

Embodiment 2

[0041] Example 2 Bacterial Biofilm Composite Microneedles

[0042] A kind of antibacterial biofilm composite microneedle, its preparation method comprises the following steps:

[0043] S1. Dissolve chitosan and zinc nitrate with a molecular weight of 10KDa in water (the quality of chitosan, the quality of zinc nitrate and the volume ratio of water are 0.1:1:50), vacuum defoaming, to obtain chitosan zinc nitrate compound solution;

[0044] S2. the chitosan zinc nitrate composite solution that step S1 obtains is 0.1mL / cm with consumption 2 Spread on the PDMS microneedle mold, evacuate to 0.04MPa, hold the pressure for 3min, deflate, repeat 4 times, dry, and peel off to obtain the antibacterial biofilm composite microneedle; wherein, the length of the microneedle The diameter of the top of the microneedle body is 100 μm, and the diameter of the bottom of the microneedle body is 10 μm.

Embodiment 3

[0045] Example 3 Bacterial Biofilm Composite Microneedles

[0046] A kind of antibacterial biofilm composite microneedle, its preparation method comprises the following steps:

[0047] S1. dissolving chitosan and zinc nitrate with a molecular weight of 80KDa in water (the quality of chitosan, the quality of zinc nitrate and the volume ratio of water are 0.1:1:10), vacuum defoaming, to obtain chitosan zinc nitrate compound solution;

[0048] S2. the chitosan zinc nitrate composite solution that step S1 obtains is 0.4mL / cm 2 Spread on the PDMS microneedle mold, evacuate to 0.08MPa, hold the pressure for 2.5min, deflate, repeat 3 times, dry, and peel off to obtain the antibacterial biofilm composite microneedle; wherein, the microneedle The length is 500 μm, the diameter of the top of the microneedle body is 300 μm, and the diameter of the bottom of the microneedle body is 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com