Angular kinetic energy gravity engine

An engine and kinetic energy technology, which is applied in the direction of machines/engines, mechanisms for generating mechanical power, mechanical equipment, etc., can solve problems such as insufficient power of angular momentum engines, and achieve strong power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

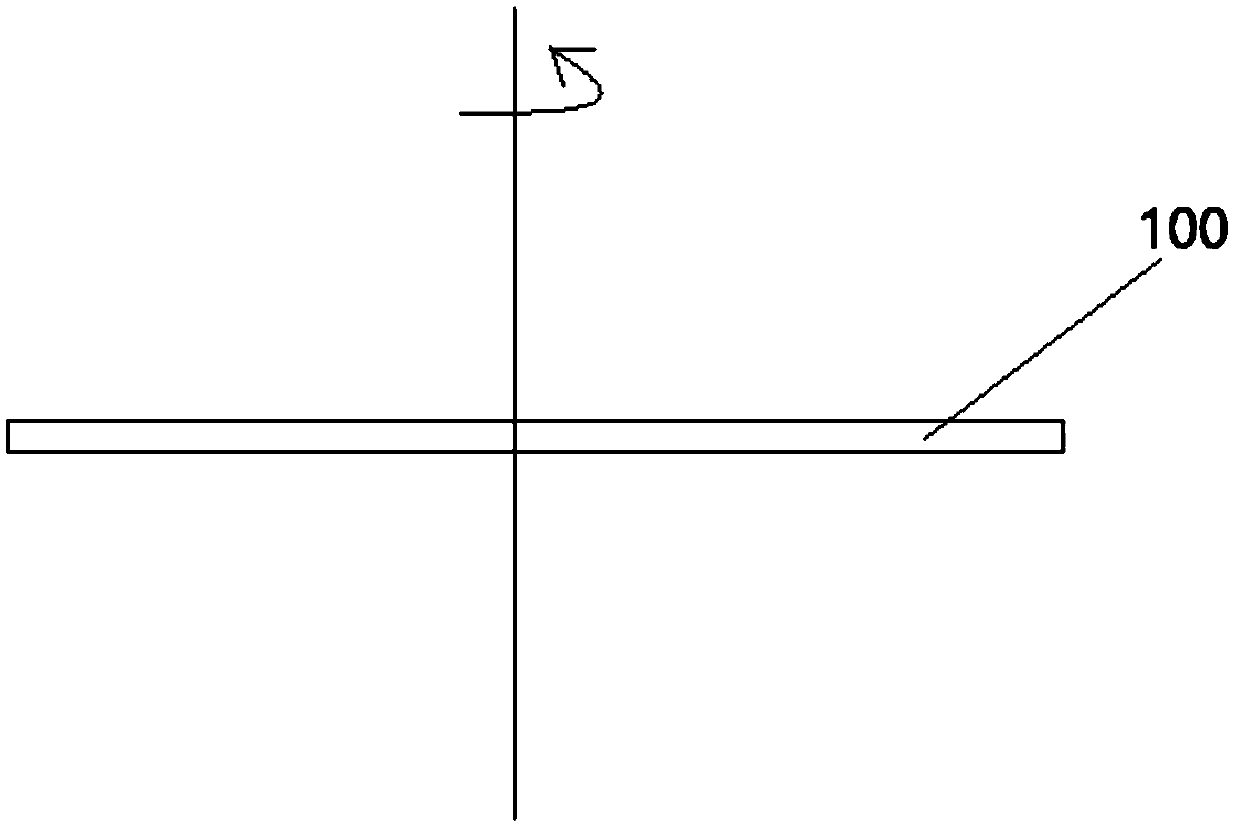

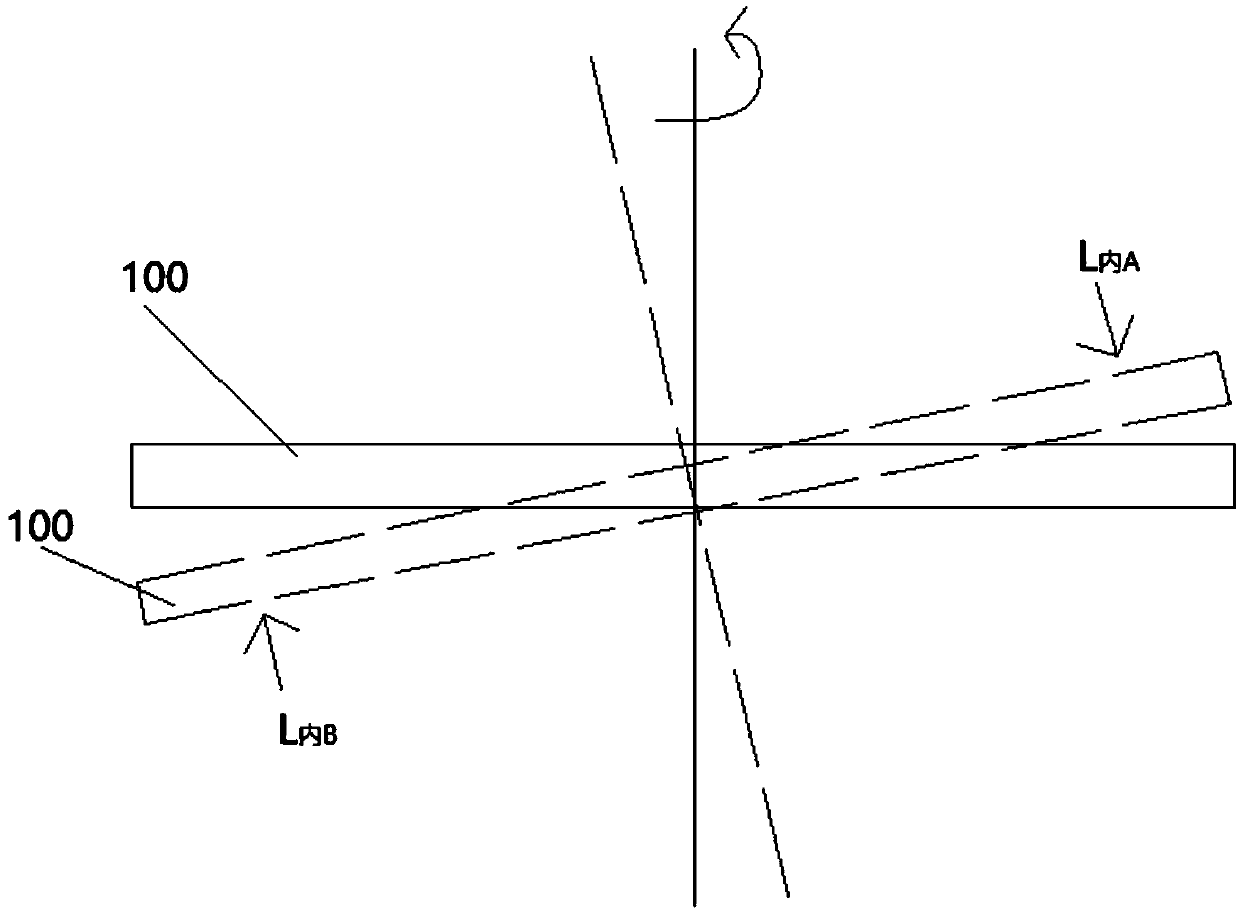

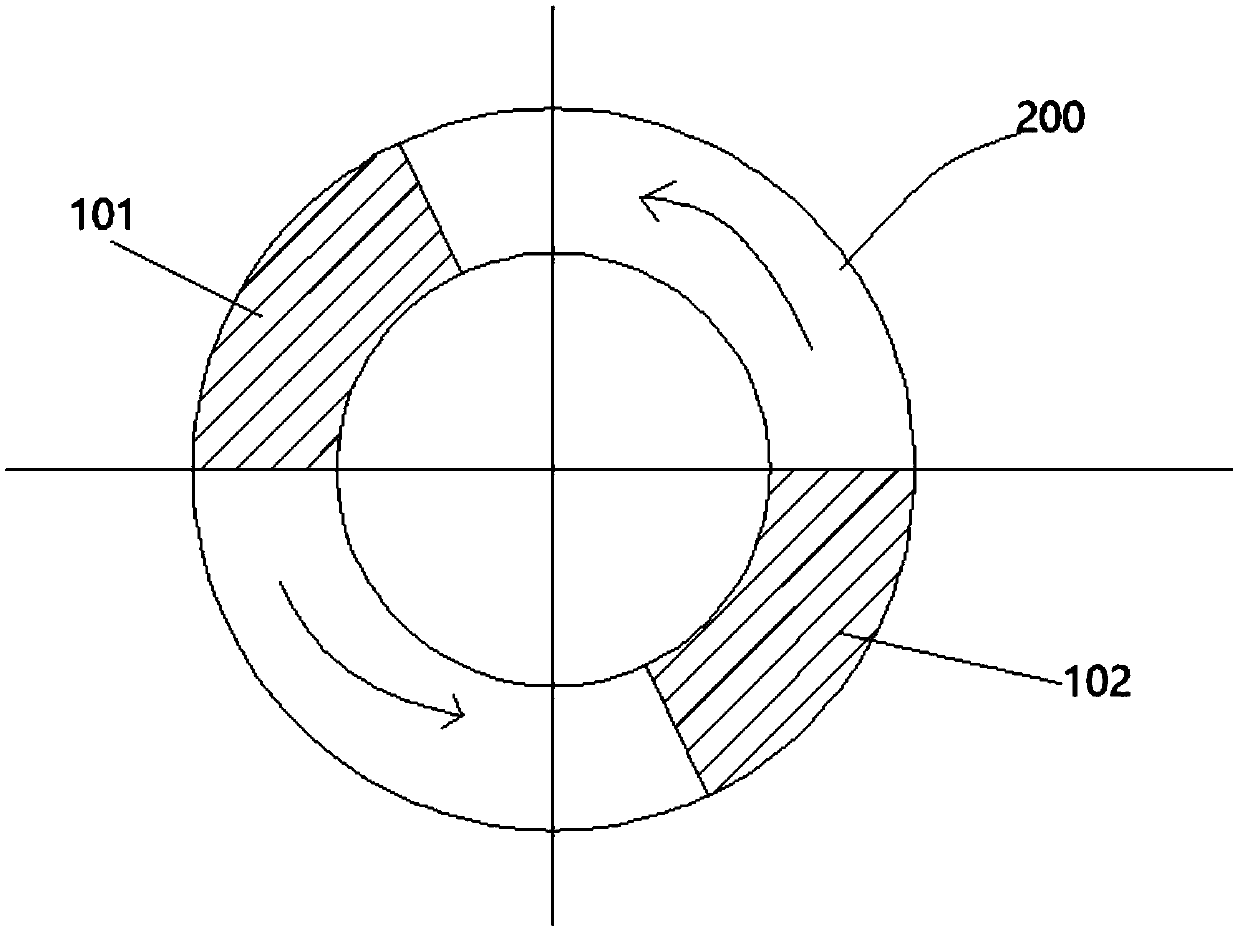

[0035] see Figure 8 ~ Figure 11, a kind of angular kinetic energy gravitational motor provided by the present invention, said motor comprises: a rotating shaft 1, placed vertically; place; an upper case cover 3, placed horizontally, shaped as a disc, with an upper casing hole 31 in the middle, through which the upper casing cover 3 is sleeved on the upper part of the rotating shaft 1, and the lower end surface of the upper casing cover 3 A cover is arranged on the upper end surface of the coil 2 along the circumferential direction of the coil 2; a bottom case cover 4 is placed horizontally and is shaped as a disc, and a lower casing hole 41 is opened in the middle part, and the bottom casing cover 4 is sleeved through the lower casing hole 41 At the lower part of the rotating shaft 1, the outer edge of the bottom case cover 4 is connected to the outer wall of the coil 2; the upper case cover 3, the coil 2 and the bottom case cover 4 cooperate to form an accommodating cavity 1...

Embodiment 2

[0060] The turntable 5 is formed by stacking an upper turntable 54 and a lower turntable 55 from top to bottom, the socket portion 51 and the connecting portion 52 are respectively arranged on the upper turntable 54, and the upper turntable 54 and the lower turntable 55 pass through a fixing member 56 Form a detachable connection. All the other are with embodiment 1.

Embodiment 3

[0062] A wear-resistant sealing ring 42 is provided between the upper surface of the bottom case cover 4 and the bottom surface of the liquid storage tank 8 . All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com