Locking buckle assembly and air conditioner

A buckle component and locking piece technology, applied in space heating and ventilation details, household heating, lighting and heating equipment, etc., can solve the problems affecting the appearance of the air conditioner, affecting the connection strength, affecting the installation efficiency, etc., to ensure Improve connection reliability, improve installation efficiency, and avoid repeated assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

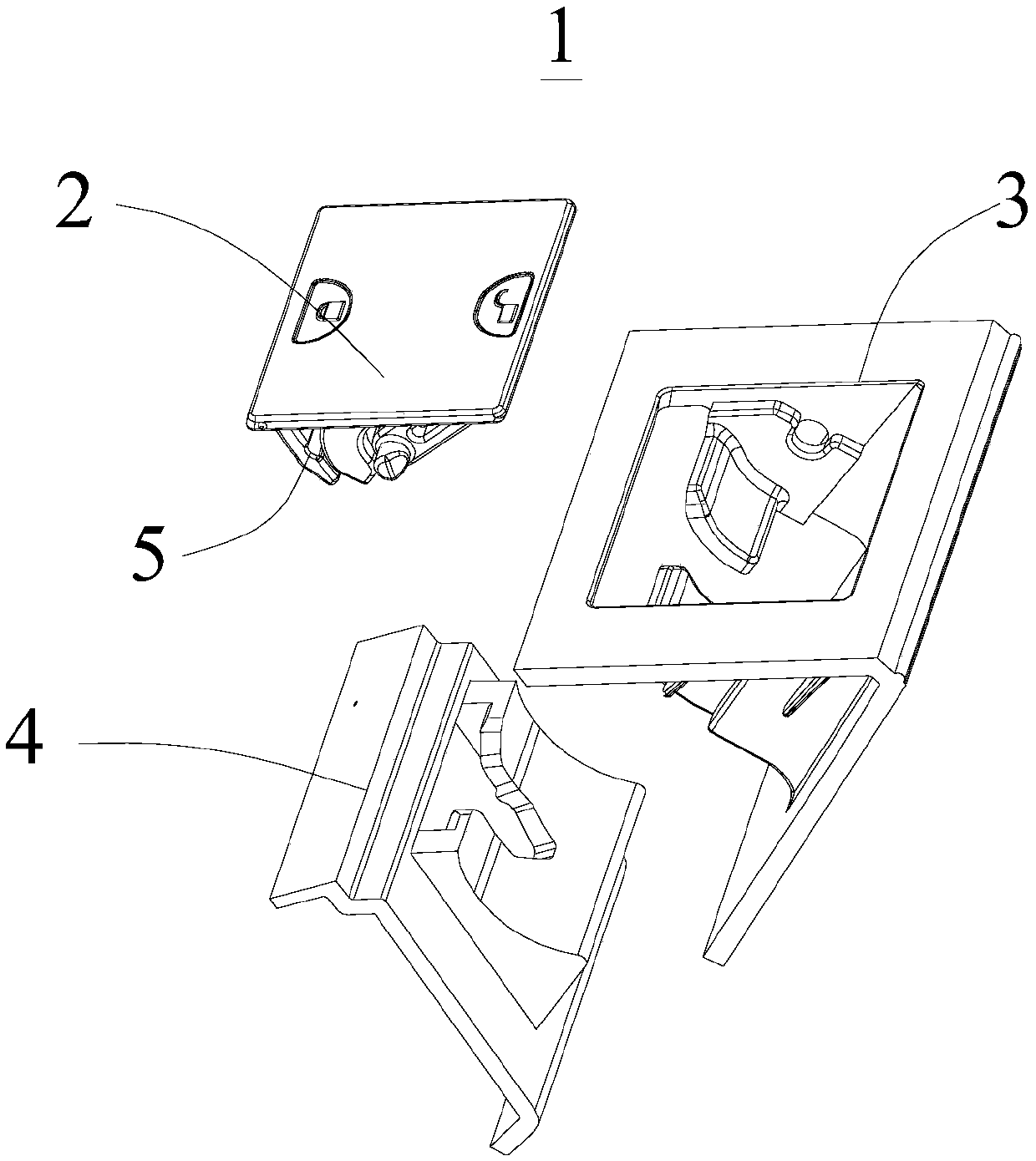

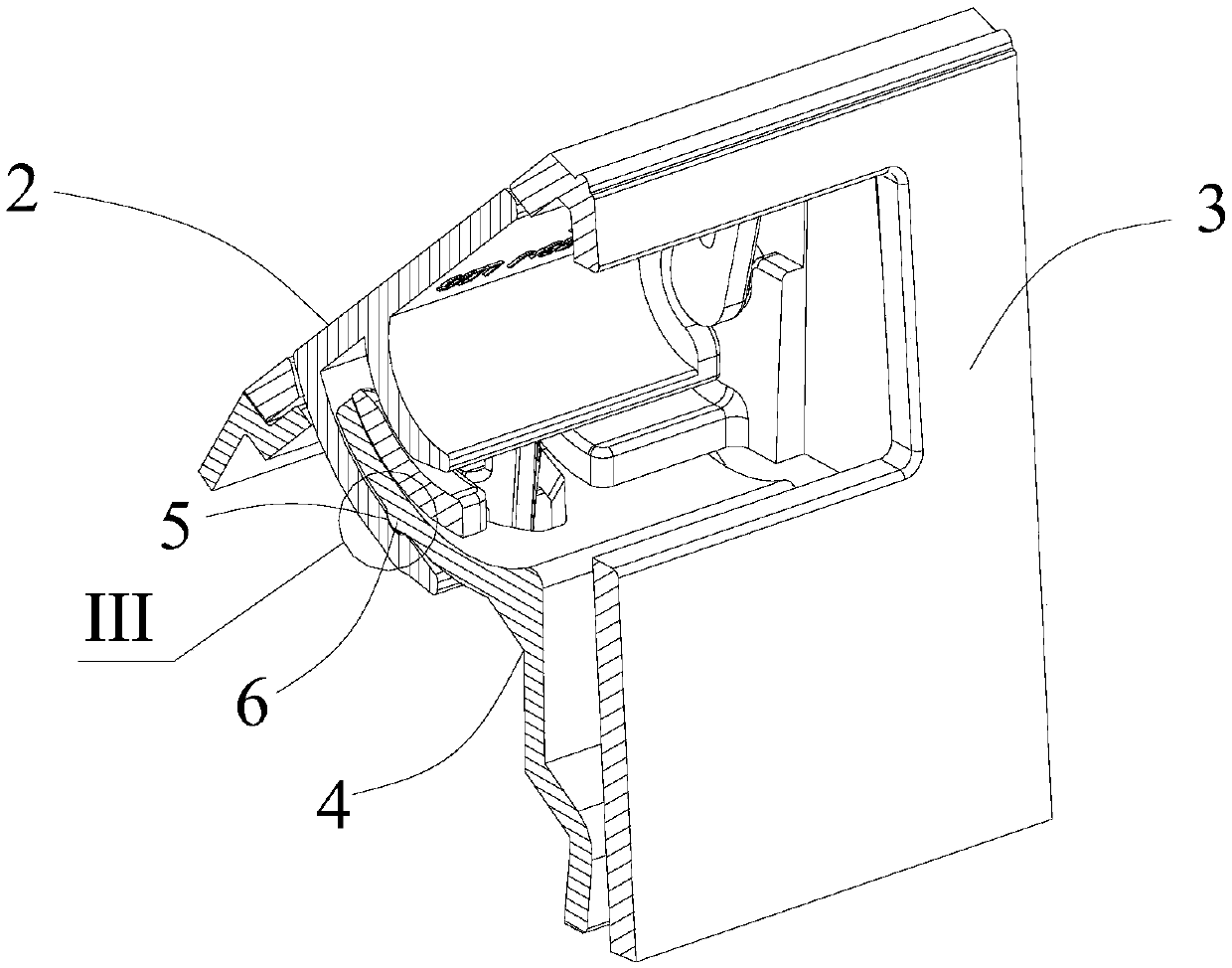

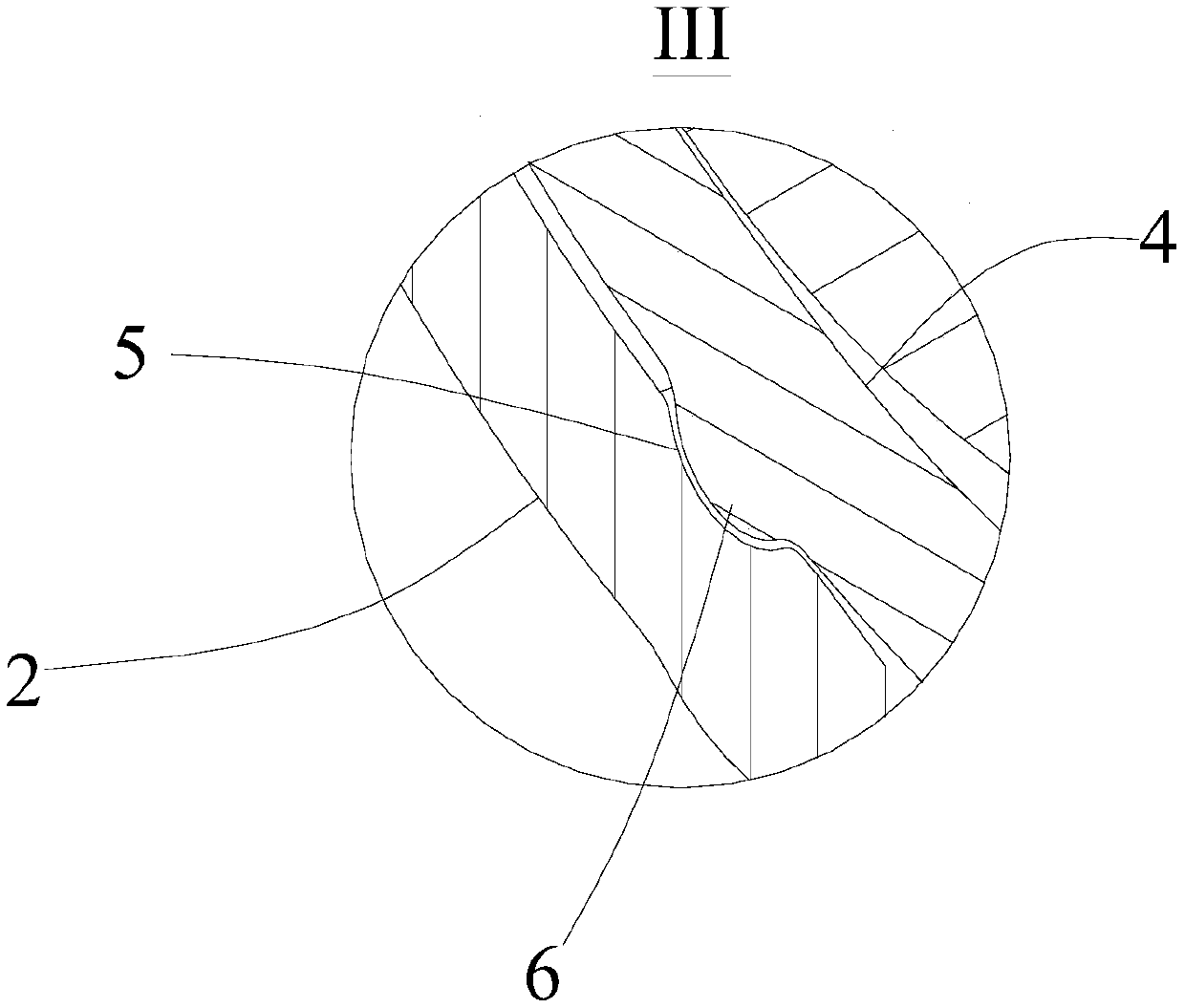

[0035] see in conjunction Figure 1 to Figure 3 , the present embodiment provides a locking buckle assembly 1, including a locking member 2, a first connecting part 3 and a second connecting part 4, the first connecting part 3 has a first connecting plate, and the second connecting part 4 There is a second connecting plate body, the locking piece 2 is rotatably connected to the first connecting part 3 and has a clamping groove structure for clamping the first connecting plate body and the second connecting plate body, and the locking piece 2 is provided with There is a first snap-in structure 5, and a second snap-in structure 6 is arranged on the second connecting part 4, and the first snap-in structure 5 cooperates with the second snap-in structure 6, so that the locking member 2 and the second connecting part 4 are connected to each other. Specifically, the locking member 2 fits and fastens the first connecting plate body and the second connecting plate body together throug...

no. 2 example

[0056] This embodiment provides an air conditioner, including a middle frame, a base, and a locking buckle assembly 1, wherein the basic structure, principle and technical effect of the locking buckle assembly 1 are the same as those of the first embodiment, and are briefly described For parts not mentioned in this embodiment, reference may be made to the corresponding content in the first embodiment.

[0057] The locking buckle assembly 1 includes a locking member 2, a first connecting part 3 and a second connecting part 4, the first connecting part 3 has a first connecting plate body, the second connecting part 4 has a second connecting plate body, and the locking The piece 2 is rotatably connected to the first connecting part 3 and has a clamping groove structure for clamping the first connecting plate body and the second connecting plate body, and the locking piece 2 is provided with a first clamping structure 5, the second The second connecting member 4 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com