Ground wire clamp

A grounding wire and fixture technology, applied in electrical connection sockets, wire-wound connectors, etc., can solve the problems of low efficiency, too many insulating rods, sore and weak hands and upper limbs, etc., and achieve the effect of reducing labor intensity and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

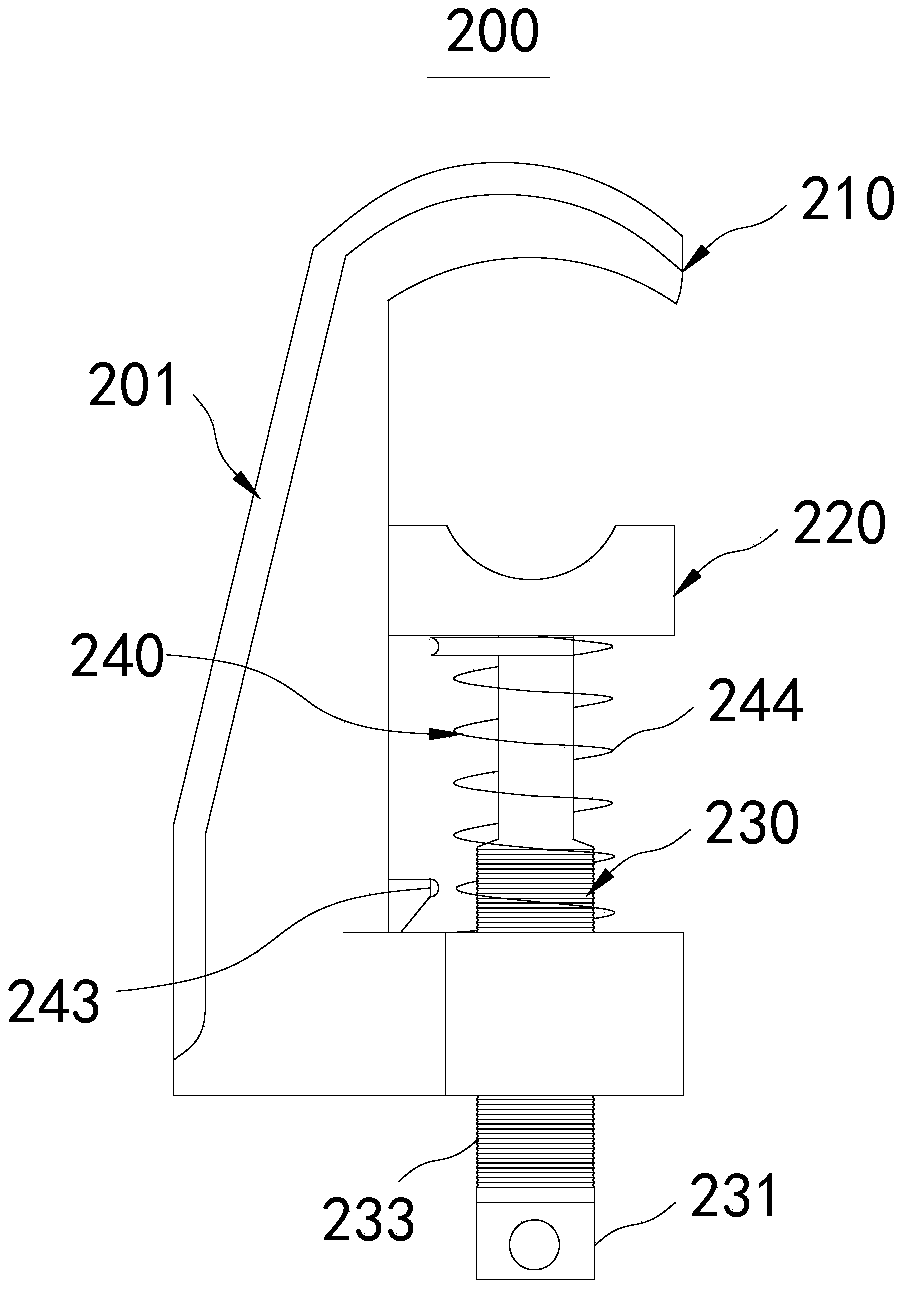

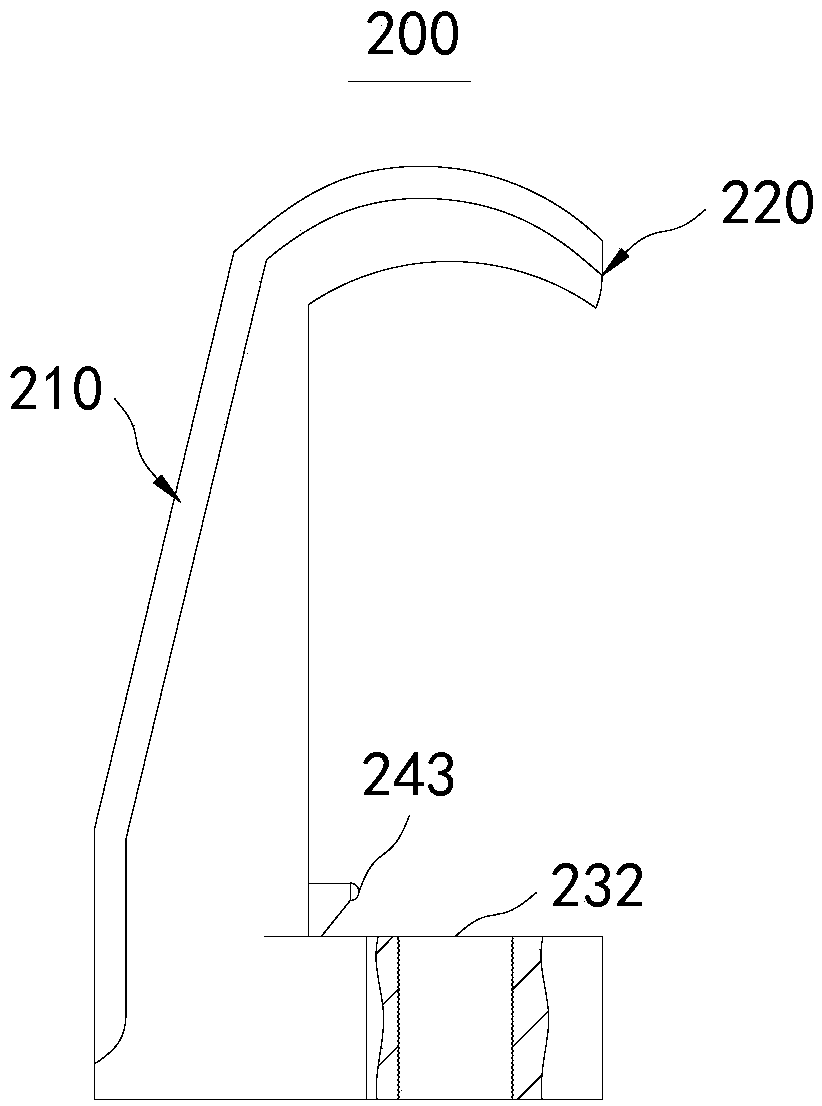

[0048] Please refer to Figure 1-Figure 3 , Figure 1-Figure 3 The specific structure of the ground wire clamp 200 provided in the embodiment is shown.

[0049] from Figure 1-Figure 3 It can be seen from the figure that the ground wire clamp 200 includes a body 201 , a first clamp 210 and a second clamp 220 .

[0050] The first clip 210 is disposed on the body 201 , and the second clip 220 is movably connected with the body 201 through the movable structure 230 .

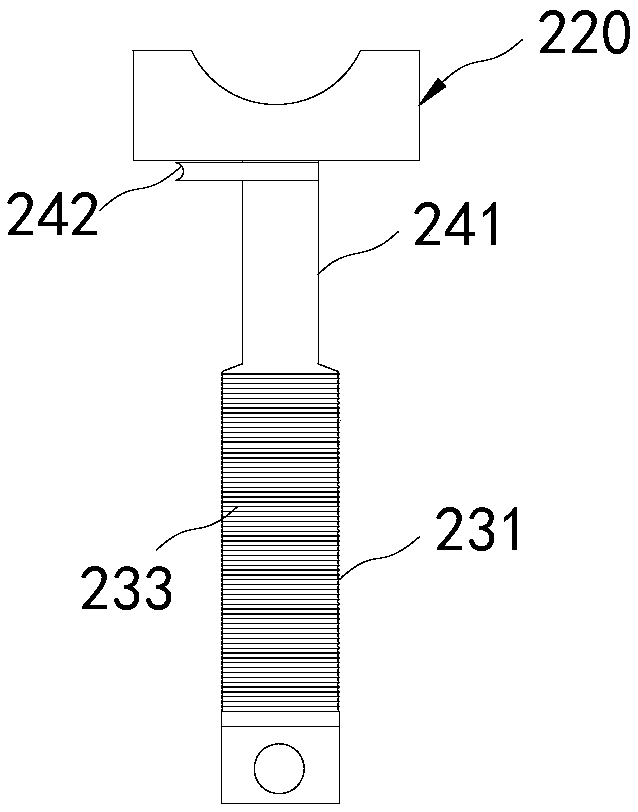

[0051] The movable structure 230 includes a screw rod 231 and a through hole 232 arranged on the body 201; the through hole 232 is arranged on the end of the body 201 away from the first chuck 210, and an internal thread is arranged in the through hole 232, and the screw rod 231 is provided with a The external thread segment 233 that matches the internal thread, the screw rod 231 is connected with the second chuck 220 after passing through the through hole 232 .

[0052] The ground wire clamp 200 also includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com