Quick washing pond for processing before production of dehydrated vegetables

A technology for dehydrated vegetables and cleaning pools, which is applied in the field of quick cleaning pools for pre-processing dehydrated vegetables, can solve the problems of poor cleaning effect, treatment affecting vegetable cleaning, etc., to achieve better cleaning effect and improve cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

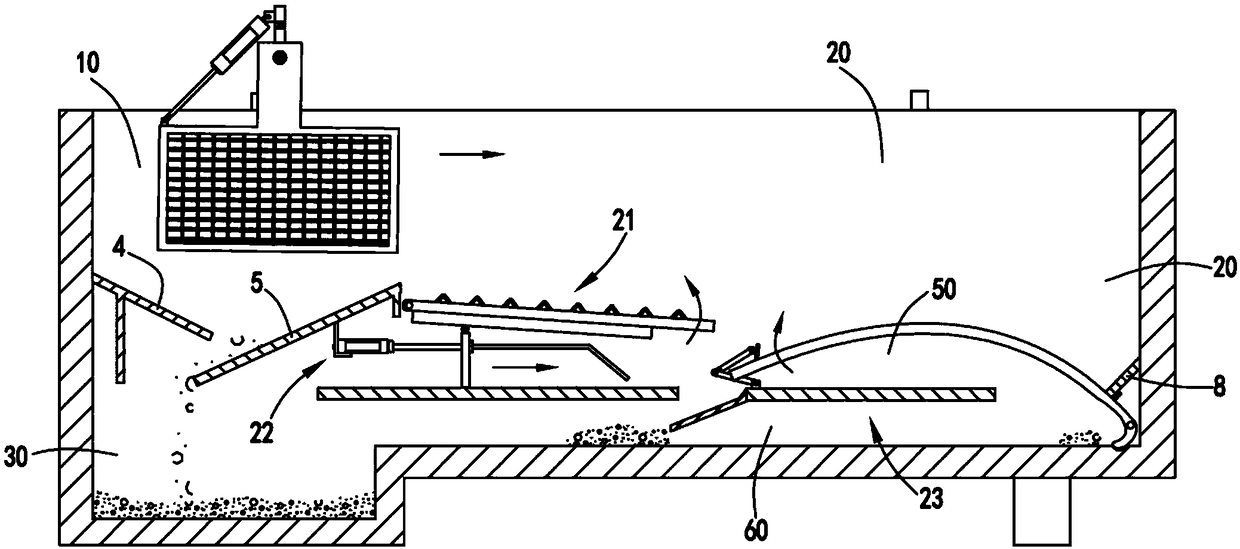

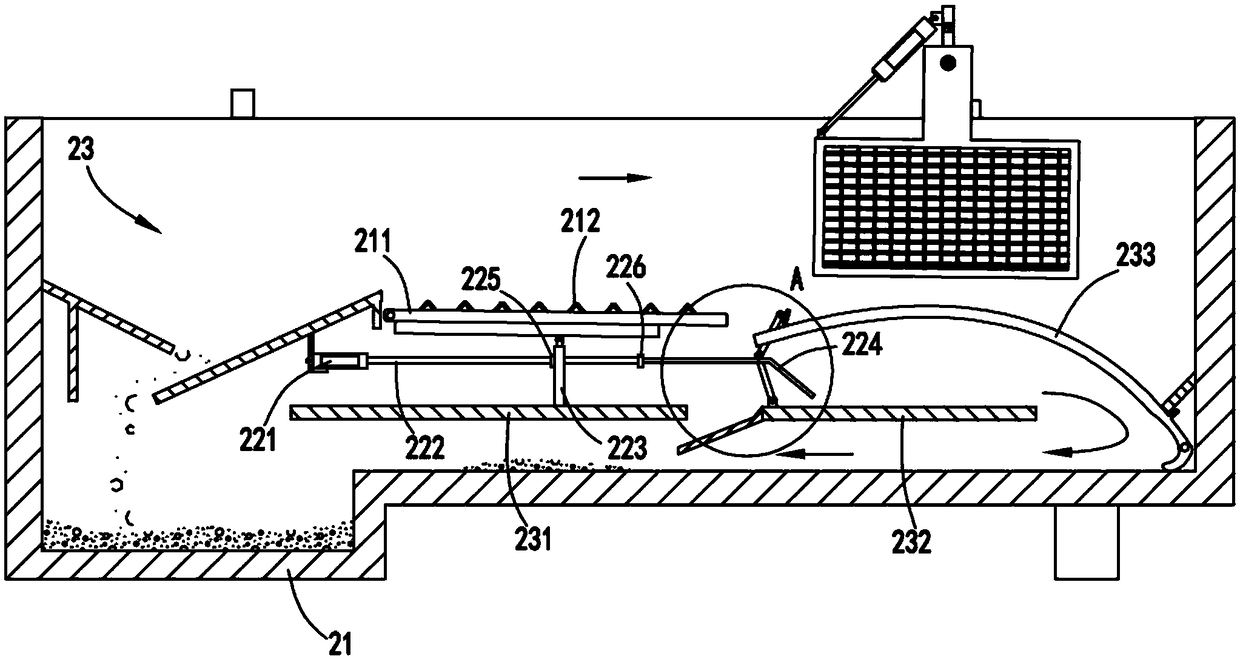

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a quick cleaning tank for pretreatment of dehydrated vegetables includes a water tank 1, and is characterized in that: the water tank 1 is divided into a primary cleaning area 10 and a secondary cleaning area 20 on the left and right, and the bottom of the primary cleaning area 10 is also A sludge accumulation area 30 is provided;

[0037] The water tank 1 is provided with a sludge cleaning device 2, and the sludge cleaning device 2 includes a surge mechanism 21 arranged below the primary cleaning area 10 for making the water surge upwards, and a surge mechanism 21 arranged below the surge mechanism 21 The horizontal pushing mechanism 22 used to push the water below the primary cleaning area 10 and the secondary cleaning area 20 to flow in the horizontal direction and cooperate with the horizontal pushing mechanism 22 to guide the flowing water flow so that it generat...

Embodiment 2

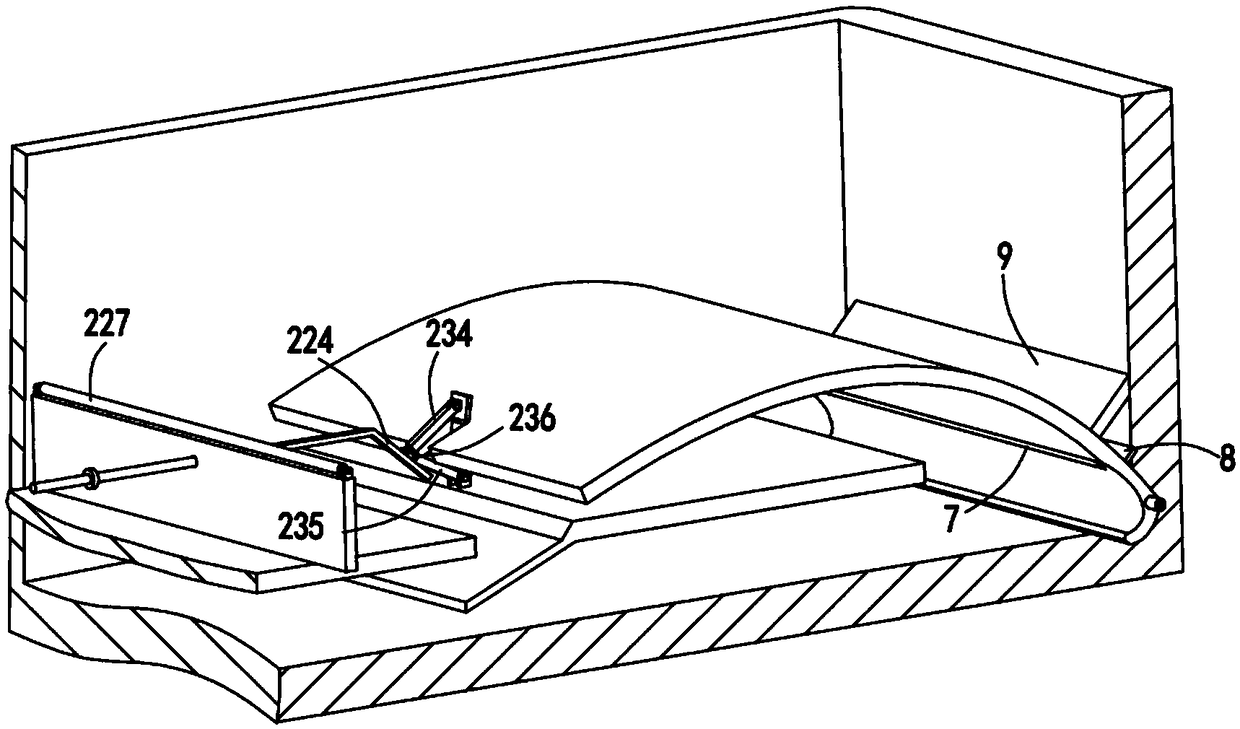

[0050] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that the transfer mechanism 32 includes a sliding seat a321 and a sliding seat b322 respectively sliding along the front and rear upper edges of the water tank 1, and the front and rear upper edges of the water tank 1 are respectively provided with limited The position block a11 and the limit block b12, the sliding seat a321 and the sliding seat b322 both include a bracket 3211 and at least two sliding rollers 3212 rotatably arranged on the bracket 3211 .

[0051] Further, the swing mechanism 31 includes a rotating shaft 311 whose two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com