Method for setting up and running an inkjet printing press for a print job

An inkjet printer, inkjet printing technology, applied in the post-processing of printing, printing, printing devices, etc., can solve problems such as interference, and achieve the effect of large color space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

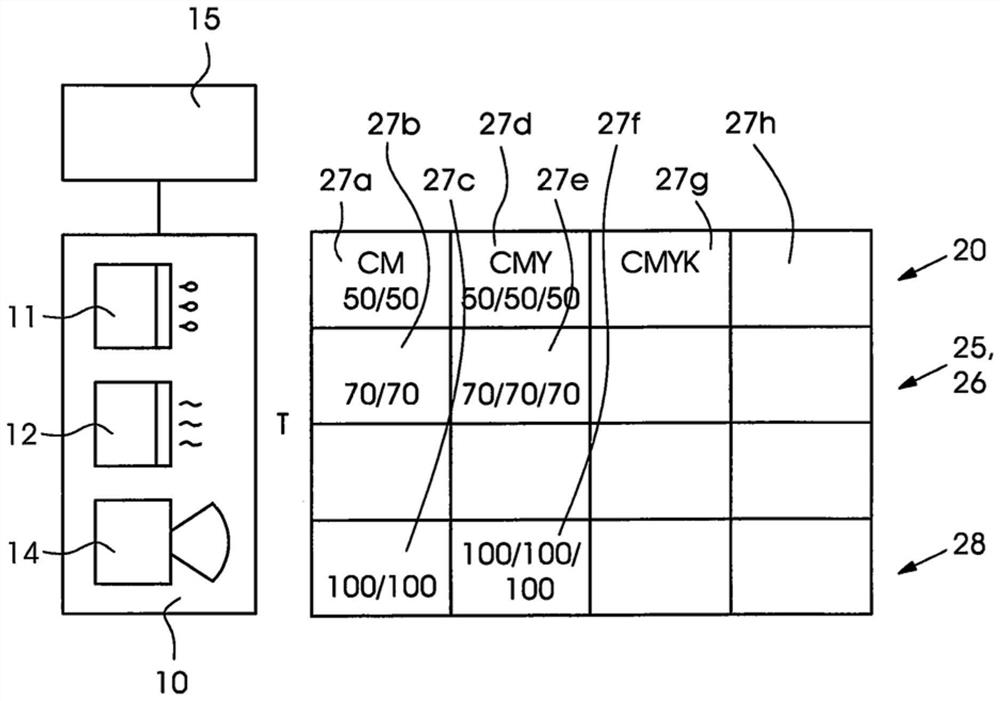

[0037] The test area 27a is printed with color inks: cyan (C) and magenta (M), where cyan is printed at 50% of the maximum possible cyan ink volume (ink limit for cyan) and magenta is printed at the maximum possible magenta ink volume 50% of the amount printed.

[0038] The test area 27e is printed with colored inks: cyan (C), magenta (M) and yellow (Y), where cyan is printed at 50% of the maximum possible cyan ink volume and magenta is printed at 50% of the maximum possible magenta ink volume. 50% is printed, and yellow is printed at 50% of the maximum possible yellow ink volume (ink volume limit for yellow).

[0039] The test area can be provided with 2, 3, 4 or more colored inks (eg cyan, magenta, yellow, orange, green, purple or other special colors). It can also be provided, as shown for example in test field 27g, that black ink is additionally printed on a test field.

[0040] Each test area 27a-h thus has a total ink volume M (total ink limit) resulting from the sum o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com