Aqueous pure acrylic reflective heat-insulation coating material and preparation method thereof

A reflective thermal insulation coating, pure acrylic technology, applied in reflective/signal coatings, coatings, etc., can solve problems such as room temperature rise, wall temperature accumulation, poor thermal insulation performance of coatings, etc., to reduce energy loss, Reduce the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

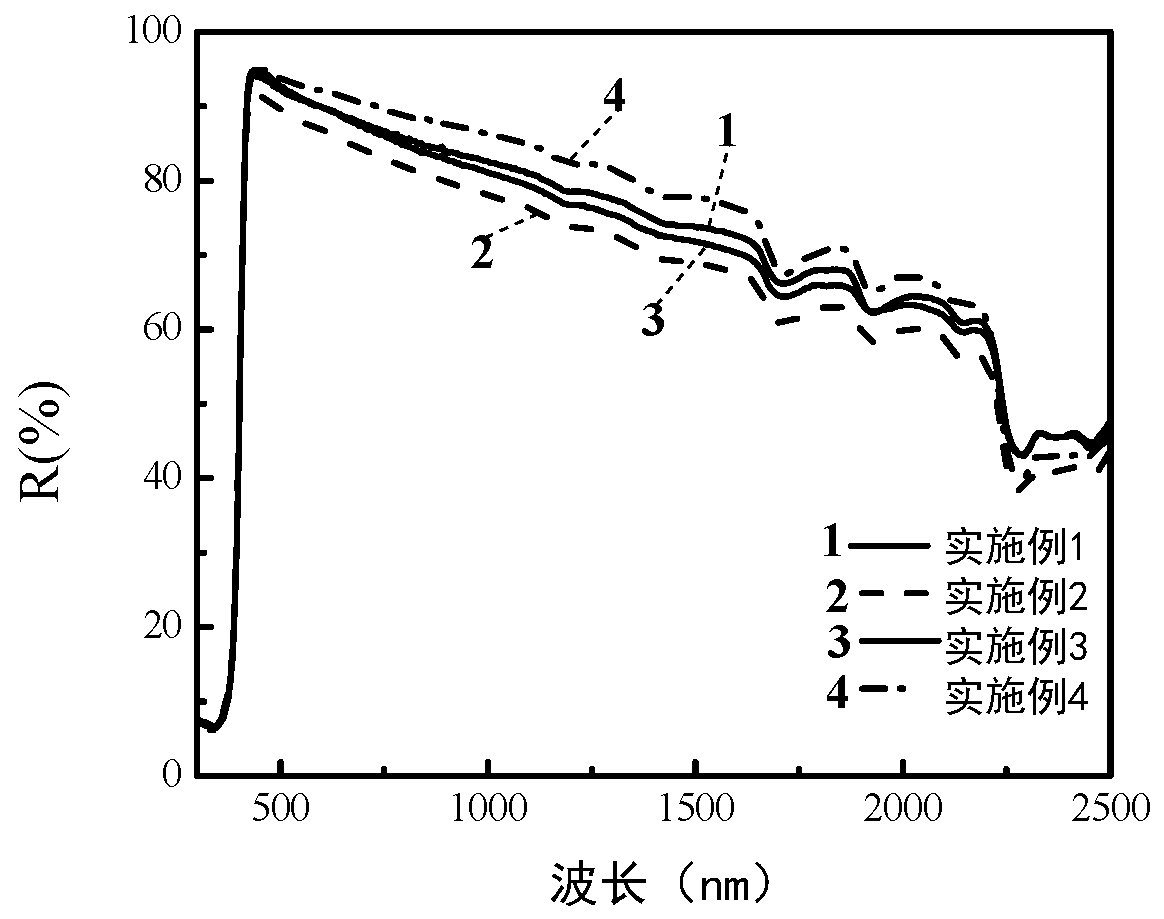

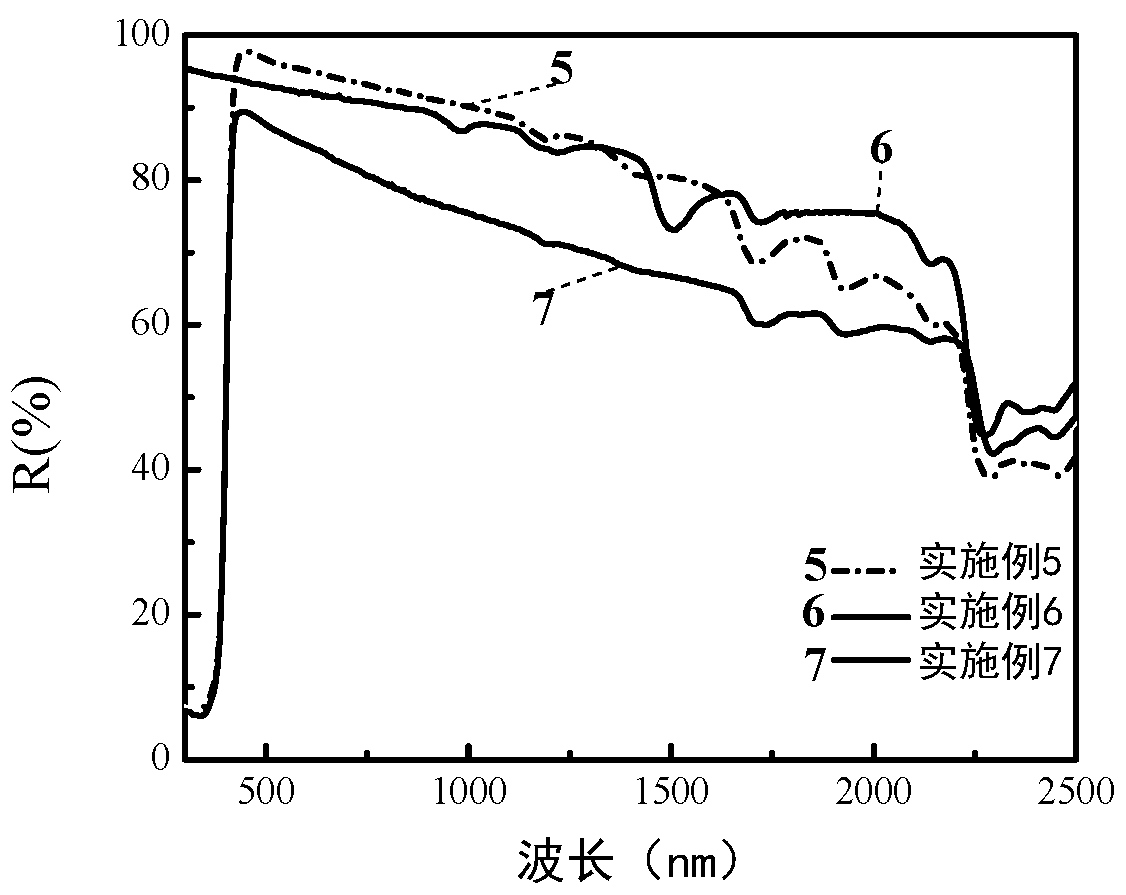

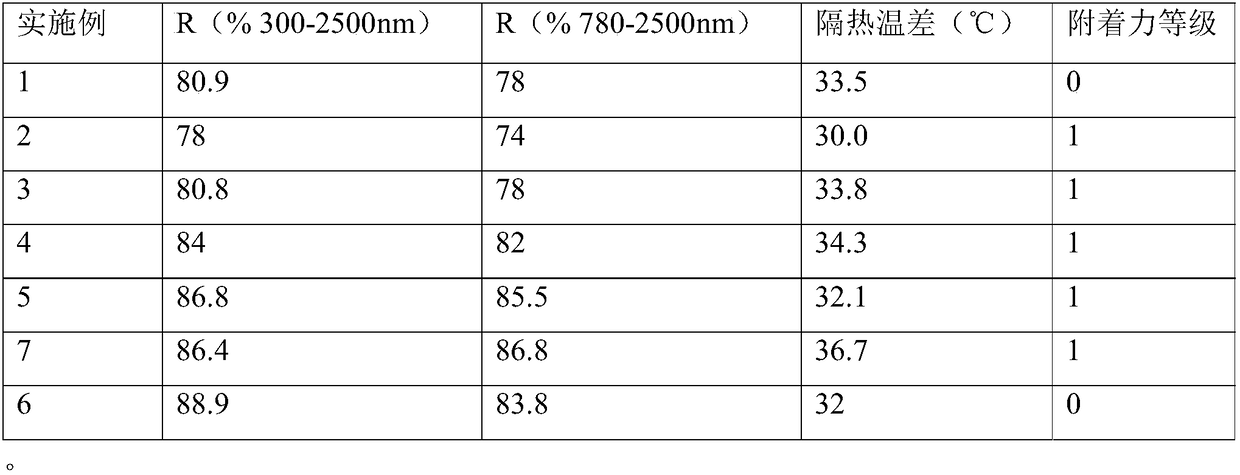

Embodiment 1

[0042] If no special instructions are used in the embodiments of the present invention include: titanium oxide (particle size 200-400nm), infrared heat reflective powder Altiris550 and infrared heat reflective powder Altiris800 (Huntsman), Clariant hydroxyethyl cellulose (Shin-Etsu Japan), 1M16K Hollow glass microspheres (US 3M), dispersant SN5040 (Qingdao Xingguo), wetting agent 752w (Tego), pH regulator AMP-95 (Dow), water-based pure acrylic emulsion (Qingdao Xingguo), leveling agent (Qingdao Xingguo) Xingguo), defoamer (BASF2410), alkali swelling thickener (BASF1125), coalescent (Dow PPH), ethyl cellulose (Shanghai Guangrui), 803 heat reflective powder (Shanghai Yutang);

[0043] Proportion by mass percentage: titanium oxide 11.7%, infrared heat reflective powder Altiris550 6.3%, infrared heat reflective powder Altiris8001%, 1M16K hollow glass microspheres 5%, water-based pure acrylic emulsion 40.8%, deionized water 25.6%, other additives Total 100%;

[0044] The preparati...

Embodiment 2

[0046] Proportion by mass percentage: titanium oxide 11.7%, infrared heat reflective powder Altiris550 6.3%, infrared heat reflective powder Altiris8003%, 1M16K hollow glass microspheres 5%, water-based pure acrylic emulsion 46.7%, deionized water 22%, other additives Total 100%;

[0047] The preparation method is as follows: add dispersant in deionized water and stir at low speed 200r / min for 20min, then add nano-scale titanium oxide, heat reflective powder and other materials and stir at high speed 3000r / min for 40min, then add other additives and cellulose and continue stirring at high speed 2000r / min for 10min , then add water-based acrylic emulsion and stir at a high speed of 2000r / min for 40min, and finally add hollow glass microspheres, and stir at a low speed of 200r / min for 120min. The prepared slurry is adjusted with a pH regulator to adjust the pH value of the slurry to prepare a water-based paint with reflective and heat-insulating functions. The aluminum plate wa...

Embodiment 3

[0049] Proportion by mass percentage: titanium oxide 10%, infrared heat reflective powder Altiris550 5.3%, infrared heat reflective powder Altiris8001%, 1M16K hollow glass microspheres 5%, water-based pure acrylic emulsion 40.8%, deionized water 27%, other additives Total 100%;

[0050] The preparation method is as follows: add dispersant in deionized water and stir at low speed 200r / min for 20min, then add nano-scale titanium oxide, heat reflective powder and other materials and stir at high speed 3000r / min for 40min, then add other additives and cellulose and continue stirring at high speed 2000r / min for 10min , then add water-based acrylic emulsion and stir at a high speed of 2000r / min for 40min, and finally add hollow glass microspheres, and stir at a low speed of 200r / min for 120min. The prepared slurry is adjusted with a pH regulator to adjust the pH value of the slurry to prepare a water-based paint with reflective and heat-insulating functions. The aluminum plate was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap