Drawing frame roller non-stop automatic refueling device

A technology of automatic refueling and refueling device, which is applied to mechanical equipment, engine components, engine lubrication, etc., can solve the problem of frequent manual refueling, etc., and achieves a high degree of automation and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

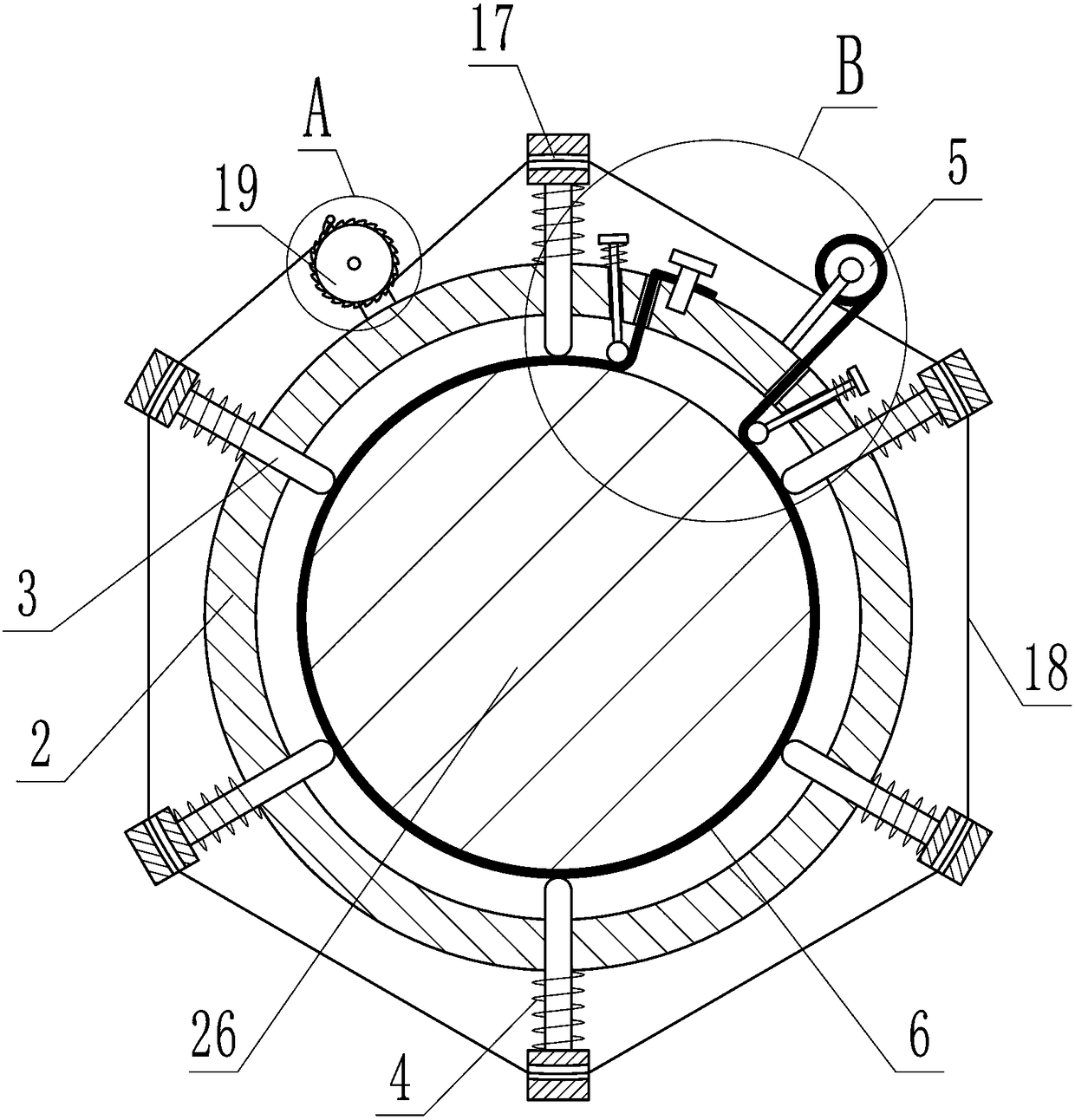

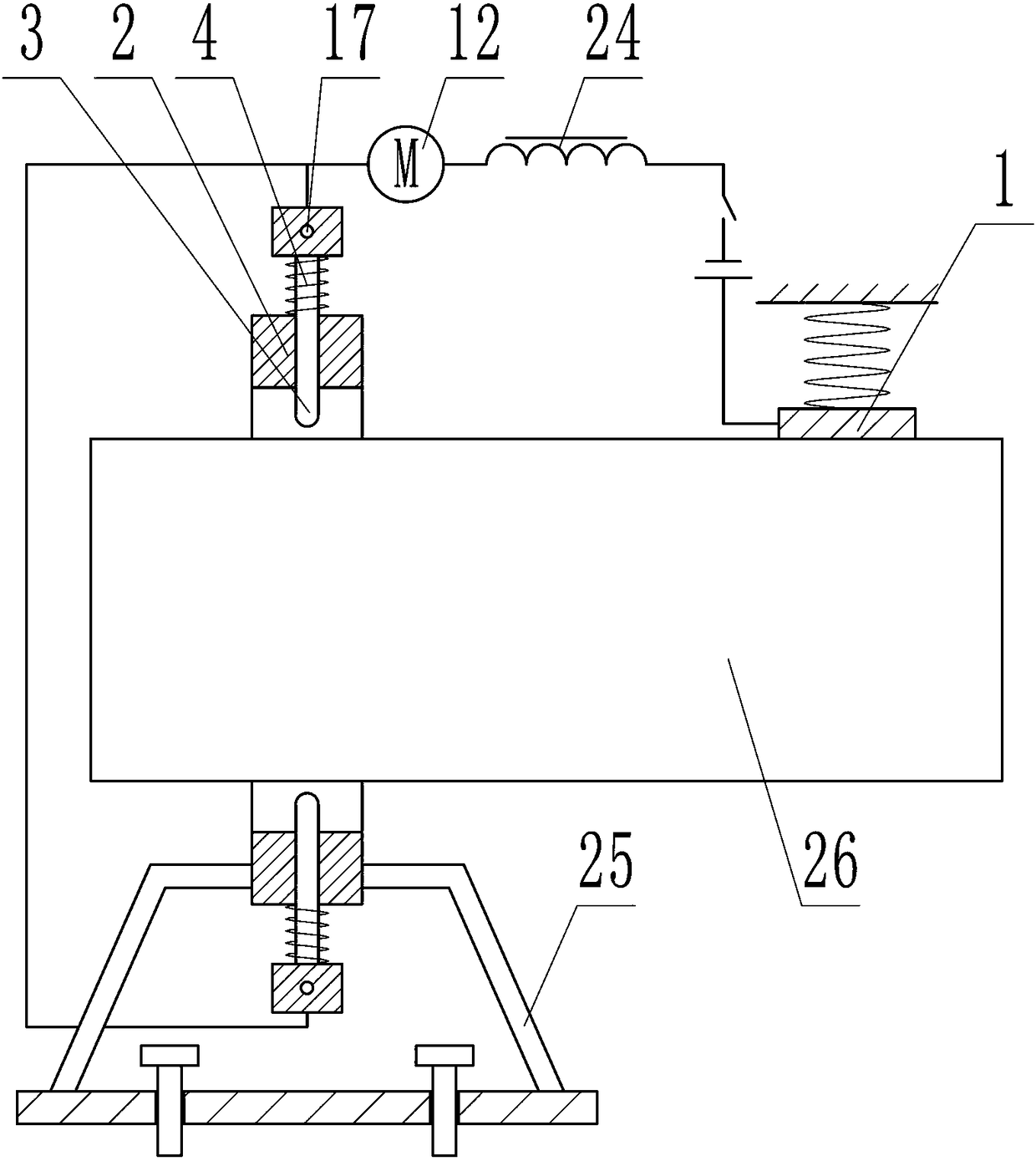

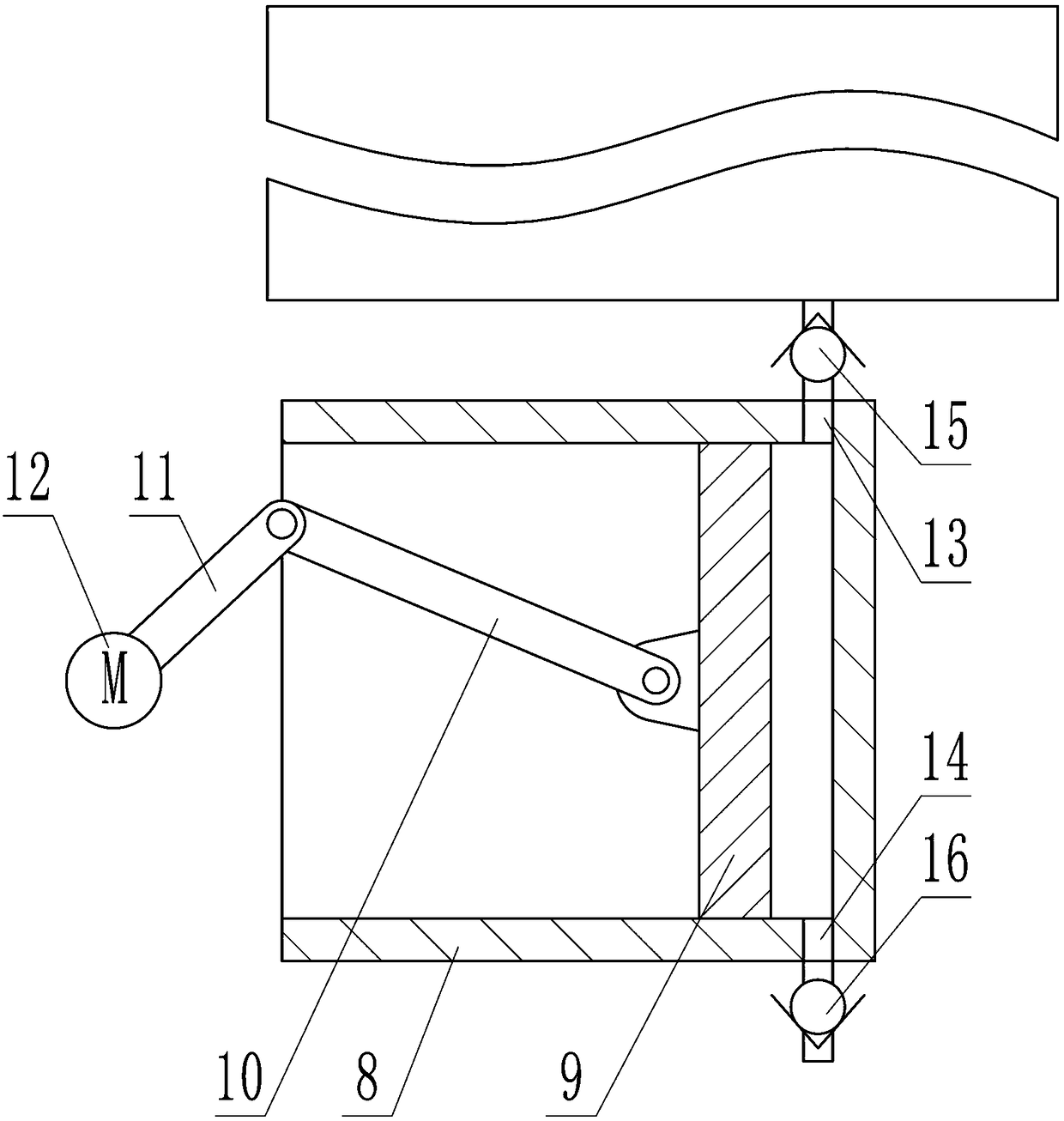

[0017] Depend on Figure 1 to Figure 5 Given, the present invention includes detection device and refueling device, and detection device comprises a brush 1 and an annular sleeve 2, and annular sleeve 2 is coaxially sleeved on the mandrel of top roller, and the circumference of the side wall of annular sleeve 2 is evenly distributed A plurality of conductive guide rods 3 passing through its side wall in the radial direction, the plurality of guide rods 3 can move radially along the annular sleeve 2 at the same time, and the outer end of each guide rod 3 and the outer wall of the annular sleeve 2 are connected with a second A compression spring 4; a circle of steel belt 6 is arranged in the annular sleeve, and the steel belt 6 can be wrapped around the mandrel and can be closely attached to the mandrel;

[0018] The refu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com